6 cost-saving inventory control techniques to optimise your stock management

Inventory control techniques that help optimise your stock management

Instead of focusing on organising warehouses, tracking goods, and picking and packing efficiently, in this blog, we examine the best inventory control methods to manage your inventory well and ensure stock availability.

Effective inventory control techniques are at the heart of efficient supply chains, ensuring products are in the right place at the right time to fulfil demand and ensure customer satisfaction.

We all know that inventory takes up valuable warehouse space, ties up capital and impacts the bottom line. Therefore, it’s important to invest in products that will sell to optimise inventory turnover and warehouse space.

We all know that inventory takes up valuable warehouse space, ties up capital and impacts the bottom line. Therefore, it’s important to invest in products that will sell to optimise inventory turnover and warehouse space.

In this post, we’ll examine six inventory control techniques to help you control your stock levels, optimise your inventory and maximise profits.

What is inventory control?

Inventory control involves managing and regulating the supply, storage, and distribution of stock. It is a key supply chain management function that maintains appropriate stock quantities to meet customer demand at the lowest cost to the business.

What is stock optimisation?

Stock optimisation aims to have the right products in the right place at the right time as efficiently and cost-effectively as possible. Stock optimisation (also known as inventory optimisation) is key to ensuring that inventory control techniques are effective. It’s the art of ensuring stock availability while reducing inventory costs and minimising the risk of excess items. This is achieved by forecasting demand and managing supply variables while continually adjusting stock rules and inventory parameters.

Six inventory control techniques to optimise stock levels

1. Understand your demand

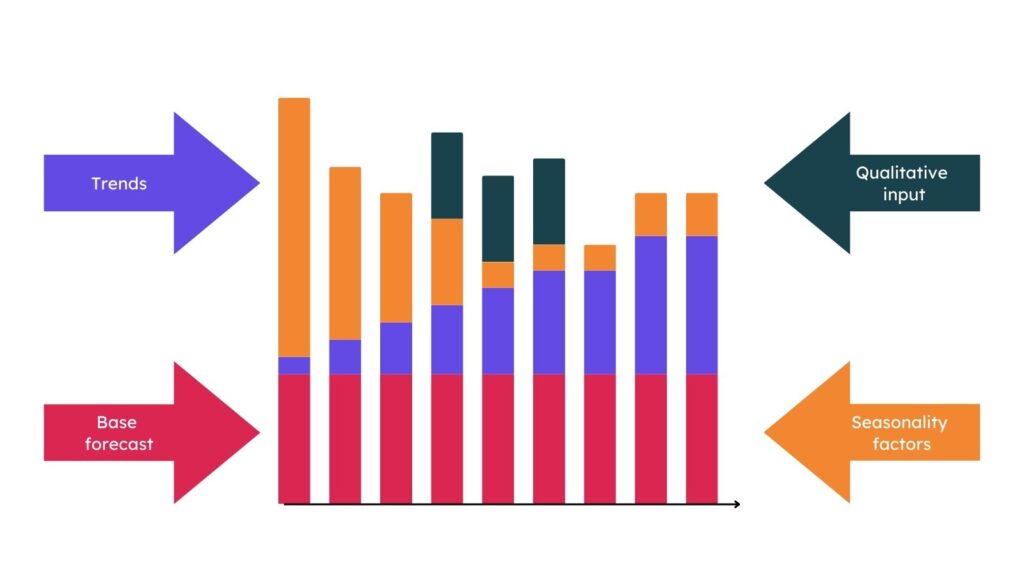

Our first inventory control technique focuses on demand forecasting. Understanding which products to carry to satisfy market demand is crucial in controlling your stock levels. It’s critical to invest time (and money if required) in setting up advanced inventory forecasting models that produce accurate demand forecasts. It’s not enough to look at last year’s sales figures and expect this year’s to follow the same pattern. Effective forecasting should consider the following:

Product lifecycles: Every item in your warehouse is at a specific stage in its product life cycle. Each life cycle stage affects the item’s demand pattern, so it needs to be considered when calculating forecasts. Read our blog on demand forecasting accuracy for more details.

Seasonality: Identify any products in your portfolio that have seasonal demand variations. It’s best practice to keep seasonal demand factors separate from your base demand calculations. This helps keep the data clean and makes forecasting easier going forward.

Trends: Product demand is influenced by fashion, technology, social, economic and legal factors. Monitor these trends in your historical demand data and adjust your forecasts accordingly.

Qualitative factors: Include any qualitative forecasting elements, such as sales promotions, competitor activity or external market events in your data.

Improving the accuracy of your demand forecasts will improve the accuracy of your ordering. When reordering and demand profiles match, excess stock and stockouts will reduce. This will free up capital and increase revenue that would otherwise be missed due to lost sales.

Many factors cause demand variability – our eGuide has more details:

2. Know your star products!

ABC inventory analysis is an excellent technique for segmenting your warehouse stock by the value it brings to the company. Each item in your warehouse has a different value in terms of the revenue it generates. There are many ways to define ‘value’, including segmenting based on sales revenue, profitability, sales volume or annual consumption value. Choose one that suits your needs. Then divide your stock into categories – A, B, and C. ‘A’ represents the items critical to your business’s success, and ‘C’ represents the least important.

ABC classification is a simple method for identifying your essential products so that you can concentrate your stock control and management time. It can also help you establish more targeted stock control parameters, as we discuss next.

However, it’s a basic framework and doesn’t consider supply and demand variables. Inventory optimisation software enables multi-dimensional item categorisation. Segmenting SKUs by demand, inventory turnover, and profitability provides deeper insight into how to control your stock levels.

You’ll be able to prioritise the most profitable items and reduce the number of slow-moving items to maximise space, reduce investment and boost revenue.

3. Set stock level control policies

Inventory policies help ensure you stock the right goods in the right quantities. This is essential for effective inventory control and warehouse management, so ensure you have a set of ‘rules’ for each SKU.

Inventory classification methods like ABC analysis can help with this by guiding you in different service levels, safety stock levels and reordering parameters for each category.

Include a policy for reducing excess stock and removing obsolete items. Not only does excess stock negatively impact stock turnover and eat into working capital, but if it becomes obsolete, it will erode your profit margins.

Another consideration here is the cost of storing stock. For example, using the economic order quantity formula (EOQ) to find the order quantity where the costs of ordering inventory and storing it are at their lowest.

You should also set useful inventory KPIs when setting stock level control policies. While this might sound obvious, it’s worth reviewing your current KPIs to ensure they’re contributing to meeting business objectives and improving efficiency, customer service and profitability.

4. Introduce service level targets to optimise stock

A target service level measures the probability of having the correct quantity of an item in stock when it’s requested for delivery so that there is a completely fulfilled order.

Consider your customers’ availability and delivery time expectations when setting target service levels. For example, suppose a seven-day lead time is acceptable to your customers. You might be able to lower your inventory levels and rely on smaller purchase quantities, reducing tied-up capital, or you could place on-demand orders with your suppliers if they have short lead times for you.

Remember, providing higher service levels than required costs your company money. However, failing to meet customer expectations can lead to lost sales and a damaged reputation. So you need to find a balance.

Service levels will also influence your stock turnover rate. Aim for higher service levels on faster-moving items and lower them for those with less demand, so you can keep your turnover rate high and avoid tying up capital unnecessarily.

5. Fine-tune your stock replenishment strategies

You can only optimise stock levels if you have informed inventory purchasing practices and only order the amount of inventory you need.

Most businesses reorder when they reach a fixed date or when stock drops to a specified level known as the reorder point. Most enterprise resource planning (ERP) and warehouse management systems (WMS) will either reorder a fixed or variable amount to meet a minimum or maximum stock level. However, if these methods cause stockouts or excess stock, you should consider a more ‘informed’ or dynamic approach that factors the following variables:

- Demand forecasts

- Supplier lead times

- Cost-effective order quantities

Incorporating supply and demand variables into your stock replenishment planning will improve ordering accuracy, prevent stock build-up and reduce capital investment.

6. Carry safety stock to reduce the risk of stockouts

SSafety stock, also called buffer stock, is held to prevent stockouts and back orders when forecasts are exceeded or supply is delayed. Safety stock minimises disruptions caused by demand fluctuations, supply chain disruptions and fulfilment issues, with minimal capital investment.

Many businesses using WMS, ERP and inventory management systems use a basic stock days model to calculate safety stock. They typically calculate the number of days or weeks of demand and add enough buffer stock to cover any variance. For example, four weeks of cycle stock and two weeks of safety stock.

However, this ‘one-size-fits-all’ approach assumes that all goods in the warehouse have similar demand and behaviour patterns. Which, as we’ve already discussed, isn’t usually the case. The more accurate your safety stock calculations, the less likely you will experience out-of-stock or overstocking situations. When calculating safety stock, the most important factors to consider are:

- The desired service level

- Forecasting accuracy

- Lead time (or delivery variation)

A sound statistical approach to safety stock calculations maximises customer service and minimises inventory cost and investment.

For more information on calculating safety stock, download our eGuide below.

It’s time to review your inventory control methods

Optimising your stock levels is impossible without considering supply and demand variables. Therefore, effective inventory control techniques rely on stock optimisation strategies.

Using standard ERP, WMS systems or spreadsheets to manage stock control procedures has functional limitations, which is where inventory optimisation software comes in.

Inventory optimisation software reduces time-consuming inventory control, automates inventory management processes to boost efficiency and reduce costs. The advanced algorithms and functionality of inventory optimisation tools make inventory management calculations faster and more accurate.

Cloud-based inventory optimization software integrates easily with ERP systems, enhancing inventory management capabilities and highlighting areas for improvement. With and deliver a fast return on investment.

Connecting specialist inventory optimization software eliminates the need for manual inventory classification calculations. Instead, the advanced stock classification functionality dynamically groups stock items using key properties at a more granular level to provide stock availability for each group.

Regular algorithm updates adjust forecasts, safety stock levels, and demand planning to maintain accuracy and optimal stock levels.

Optimizing inventory saves money by reducing stock levels without hurting service levels. In many cases, service levels increase thanks to improved efficiency and automated alerts for when items are at risk of stockouts.

Software like EazyStock provides an affordable way to optimize inventory management and improve efficiencies. Customers typically reduce inventory levels by 30%, resulting in 25% fewer holding costs and a 15% improvement in stock availability.

EazyStock has a unique customer support model with dedicated customer success managers for each customer. Outside the subscription fee, there aren’t any hidden costs for ongoing support or system upgrades. Our annual fee includes all customer updates and training, so you don’t need to allocate additional budget for any unexpected costs.

If you need help with your stock management, get in touch to understand how EazyStock can help you save money with a fast return on investment.

Originally published 03/08/2015, updated July 2020 and May 2024.