The inventory planners guide to managing the product life cycle

Every product goes through several phases from its launch to eventual phasing out, which is known as the product life cycle.

The product life cycle model is not only important to marketing teams and product managers, it’s also critical to inventory planners managing demand forecasting and stocking policies. In this blog post, we’ll find out why!

Introducing inventory life cycle management

The product life cycle describes the different stages a product goes through, from the moment it gets introduced to a marketplace until it’s finally removed from sale. Inventory planning is very closely linked to the product life cycle because each stage dictates an item’s demand pattern. Inventory life cycle management is the process of treating inventory items differently, in terms of adjusting demand forecasting methods, stocking policies and reordering parameters, according to where they sit in their product life cycle. There are four key inventory life cycle stages:

- Launch stage or introduction stage

- Growth stage

- Maturity stage or mature stage

- Decline stage

The product life cycle and inventory management

Product life cycle management is a long-established business management technique that defines the various stages of a product in the marketplace – from market introduction to end-of-life. Almost every product is limited to how long it can successfully be sold to customers. Some products will have a shorter product life cycle, due to changing technology and consumer tastes, e.g. a mobile phone or fashion item. Other products will last much longer, e.g. branded groceries.

Supply chain managers need to work with other departments to make critical decisions about each product’s future. Therefore, supply chain managers and inventory planners need to know the life cycle stage for every inventory item they manage. By improving visibility and control of the product life cycle, inventory managers can reduce risk and costs, while enhancing the customer experience.

Product life cycle management brings together data, people and processes to find the optimal level of product availability and risk at each stage of the product life cycle. This is to ensure stock levels reflect the associated customer demand continually. This short video will help explain:

Customer demand and the product life cycle

As a product moves through its life cycle, it will experience major changes to its demand. For example, demand could rocket during the launch stage but drop off as it reaches decline. These differing demand patterns make it more challenging for inventory planners to forecast and ensure they order the right stock levels.

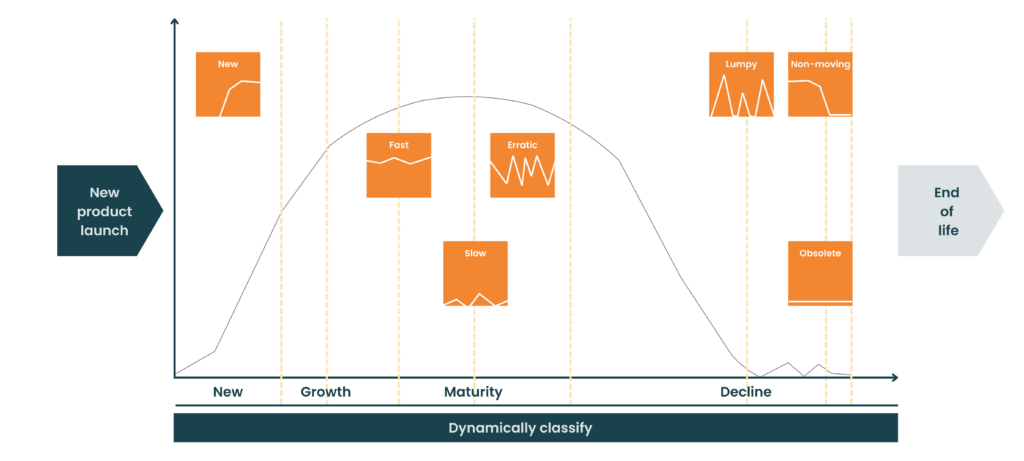

Here is a product life cycle and the corresponding demand patterns, or ‘demand types’ that EazyStock groups items into:

As existing products move through each stage in their life cycle, they will align to a different demand type (at different times and varying speeds). Inventory managers should use different forecasting models for each demand type to ensure high accuracy. This is because demand will fluctuate differently in each case, so the confidence interval (the range of values within which the eventual demand value is likely to be) will be greater or smaller. For example, it makes statistical sense to use a different algorithm to forecast demand for a product with ‘lumpy demand’ (with a typically high deviation from its average demand) to a product with ‘fast demand’ (with minimal deviation).

Stocking policies and the product life cycle

A product’s position in the product life cycle is also critical when it comes to warehouse stocking rules. Whilst basic inventory classification models, such as ABC analysis, group and prioritise products based on their value to the business, they fail to account for their position in the life cycle and consequential demand types. For example, if a product has previously sold well with good profit margins, you’d be inclined to hold generous amounts of stock. However, without knowing its life cycle position, you could increase your risk of ending up with excess and obsolete inventory, especially if the product is nearing the end of its maturity and beginning to hit a phase of decline.

How do I manage my inventory to account for stages of the product life cycle?

1. Launch stage (introduction stage)

The launch or introduction stage of the product life cycle is when a new product is first made available to the market. There’s no denying it this is a high risk time for inventory planning teams who need to understand how much of the product to order and which supplier they need to order the parts or end products from.

Even with forecasted sales figures, no one really knows how customers will respond to the product. If customers love it, you’ll need to ramp up purchasing fast. If they hate it, you could end up with high levels of unwanted stock.

With a lack of historical demand data to support forecasting, inventory planners can use data from similar product launches to assist at this uncertain time.

2. Growth stage

If a new product increases in popularity, sales will start to rise. This growth could be rapid, slow or highly sporadic, but the trend will still be positive either way. You’ll have more data to work with, so rather than using data from similar products, you can start to use quantitative data and track trends.

As a successful inventory planner, you’ll need to run frequent demand forecasts to ensure you have the right stock levels to keep up with changing demand and meet any sales targets set before launch. These forecasts should use a different algorithm to the one used at the launch stage.

You’ll also need to keep a close eye on safety stock, which can be used to support any surges in sales. With sales in a steady growth phase, it could also be wise to analyse your reorder points to optimise their cost model.

3. Maturity stage (Mature stage)

Once a product is well established in its market, growth slows and begins to level off. In this stage, inventory planners typically see erratic, slow or fast demand patterns, depending on the product and its market. Again, you’ll need to carry out frequent forecasts to ensure stock levels are optimised.

As an item begins to reach the end of its maturity phase (mature phase) and hit decline, stock managers need to start taking action. This comes in the form of lowering the number of inventory items you’re holding, ready for the final drop in demand. This can be done by:

- Lowering target service levels: It can be challenging for companies to reduce the availability of products to the market and risk stockouts and missed sales. However, if businesses don’t, they face holding excess inventory (e.g. overstock that doesn’t have a defined customer demand) or even costly obsolete inventory (stock with zero demand).

The costs associated with carrying large quantities of excess or obsolete stock can be a substantial financial burden for any business. The key is to re-forecast demand regularly and make replenishment adjustments accordingly. - Reduce safety stock levels: You should reduce your safety stock’s reordering frequency or replenishment levels according to the slowing demand.

4. Decline stage

As trends change and new products are released to the market, some older products will experience a fall in demand. Smart inventory planners will have already seen this decline on the horizon and taken action to reduce stock levels appropriately to avoid getting stuck with obsolete goods. At the very end of the product life cycle, the excess and obsolete stock should be almost zero, to ensure your company’s cash isn’t tied up in inventory or lost altogether.

How do I calculate the product life cycle for effective inventory planning?

Effectively managing the product life cycle ensures products can move seamlessly through each stage, from introduction to decline and end of life. It also helps provide continuity to your business by improving new product development to avoid product cannibalisation and obsolete stock.

Manually calculating the product life cycle stage of all your stocked and non-stocked items can be extremely time-consuming – especially if you have an extensive product portfolio. As previously discussed, you should ideally identify these life cycle stages and corresponding demand types regularly.

If this sounds like a daunting task, consider integrating EazyStock with your business systems. As the leading inventory optimisation software tool, EazyStock will simply plug into your ERP, WMS or inventory management system and automatically forecast demand, optimise your stock levels and recommend your replenishment requirements – daily.

EazyStock not only calculates every item’s product life cycle stage and demand type but also considers seasonality, trends and sales promotions when forecasting demand and optimum inventory levels. With data updated daily, your reorder quantities and reorder points will always be based on the latest supply and demand variables. Want to know more? Download our eGuide below or contact our inventory experts here.