Importance of ABC analysis in inventory management

ABC analysis in inventory management

Managing thousands of stock items from various suppliers and delivering them to an extensive customer base is challenging. To help control such complexity, businesses can introduce models to prioritise their inventory management. They can then apply a level of control to each group, based on their importance to the business. One way to do this is to use a model such as ABC analysis, also known as ABC inventory classification.

This blog post explores how businesses can use ABC analysis (ABC classification) to improve their inventory management and stock control practices.

What is ABC inventory analysis?

Inventory management teams use ABC inventory analysis (ABC inventory classification) to classify stock items into three categories – A, B and C – based on their ‘value’ or ‘importance’ to their business.

ABC analysis is a fairly simple way to help managers focus their time and efforts on controlling more significant stock items using demand and cost per unit. They can also adapt their inventory management processes and inventory control policies for each category to help ensure they carry optimised levels of the right stock.

Using ABC analysis for stock control

Every stocked item (or SKU) does not have the same value in a business. Some items will be more profitable, urgent or critical than others, requiring more focus on forecasting, management and replenishment activities. One way to help differentiate and prioritise items is to segment them into categories (A, B, and C).

ABC inventory classification ranks inventory items based on their usage value, such as sales or consumption. Usage value is calculated by multiplying an item’s ‘usage rate’ by its ‘individual value’ or its ‘sales volume’ by its ‘unit cost’. We explain this in more detail in our blog post, ‘How to calculate ABC classification – a working example.’

- ‘A’ classification items are very important and sometimes business critical. They require the most careful control.

- ‘B’ classification items are less important than ‘A’ items and more important than ‘C’ items.

- ‘C’ classification items are marginally important and need less attention and control.

ABC inventory analysis and the 80/20 rule

You’re undoubtedly familiar with the ’80/20 rule’, also known as the Pareto Principle. This rule of thumb can also be used for inventory consumption, where a few stock items make up most of the usage value.

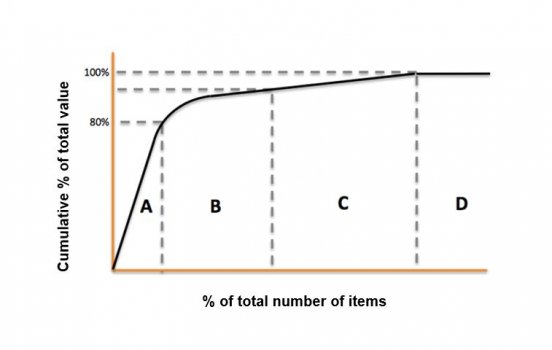

So, A items are the 20% or so of items with a high usage value. These items account for around 80% of the total usage value.

B items are the next 30% of medium usage value items, accounting for around 10% of the total usage value.

C items are low usage value items that comprise around 50% of total stock, but contribute only 10% to the total usage value.

The graph below shows how ABC inventory classification conforms with the Pareto Principle. You can see that 80% of the inventory’s total usage value comes from a small number of A category items. The remaining 20% comprises a large number of B, C and D items. In this example, we have included category D items, as some companies may want to classify their inventory beyond, A, B and C.

While the Pareto Principle might not always be 100% accurate, ABC is an easy way to find where most of a business’s revenue comes from.

Other types of ABC stock analysis criteria

Although ABC stock analysis commonly uses usage value, it isn’t the only way to classify stock. You could decide to group inventory items based on other ‘operation critical’ criteria, including:

- Risk of stock-outs – how likely items are to be out of stock

- Consequences of stock-outs – this could be based on production delays or customer service levels

- Uncertainty of supply – items with erratic demand could warrant more attention

- Item deterioration risk – items at risk of going obsolete might need extra monitoring

The importance and advantages of ABC analysis

After analysing your stock and categorising each item, you can then use the information to improve stock control and management efficiencies.

Improved inventory management process

Inventory teams can improve how they manage their time. For example, they can focus primarily on managing category A items to improve their stock availability, update demand forecasts or review stock levels more frequently.

Inventory optimisation

Knowing which products have high demand allows you to ensure you invest in the right products: those you know will sell. You can also prioritise warehouse space for A items and reduce the risk of obsolete items taking up valuable space.

ABC analysis can help you determine appropriate inventory rules such as different service levels, safety stock levels and re-ordering parameters for each category. For example, improving order quantities or safety stocks of A items could lead to significant savings overall. Improving fulfilment rates of A items could also dramatically increase overall availability.

Improved supplier relationships

Understanding your most valuable items means you can develop relationships with suppliers of your A items. This could be improving lead times or negotiating prices.

Better product life-cycle management

Monitoring items as they move between categories can help you track where they are in their product life cycle – launch, growth, maturity or decline. This means you can adjust demand forecasts and maintain high service levels for each item.

Disadvantages of ABC analysis

While ABC analysis is a relatively easy way to prioritise inventory management, it also has several limitations:

Too simplistic

ABC analysis arguably oversimplifies inventory classification. Especially if you base the analysis on ‘gut feel’ and not hard data. ABC classes are also very one-dimensional as they only consider one variable, such as sales value. Factors such as demand variability, sales frequency and pick frequency are equally important when categorising your most important inventory.

With only three categories, ABC analysis lacks granularity. Having hundreds or thousands of items in one segment doesn’t mean they have the same characteristics, so they shouldn’t be treated in the same way.

Static

ABC analysis lacks dynamism. In a marketplace with varying trends and erratic product sales, items can quickly move from category C to B or vice versa. This means your ABC classification groups can quickly become outdate without regular analysis and reclassification. Treating A products as C products or visa versa can harm a business. It couldlead to out-of-date inventory policies and stockouts or excess inventory.

Time-consuming

It takes time to constantly re-evaluate your As, Bs and Cs and look for signs of movement between the groups. This puts you at risk of your ABC classification getting out-of-date quickly. Inventory management teams spend more time classifying their goods rather than acting on the implications of the results.

Considering demand in ABC analysis

You can take ABC analysis to the next level by including the demand variability of your items. This allows you to classify products based on their value and forecastability, e.g., how likely demand will vary from the forecast.

For example, some products will have a regular demand, whilst others will have intermittent demand. This additional insight helps you to make informed decisions about which products to stock and the corresponding safety stock levels.

In its simplest form this is known as XYZ analysis and adds further categories.

- X items – regular demand

- Y items – strong variability in demand

- Z items – demand is very irregular and difficult to predict

You could also cross-analyse usage value with pick frequency or the number of times an item is sold. This can prevent over-stocking of relatively high-value, slow-moving items that don’t sell quickly. It also ensures that low-value items that sell regularly are identified as ones to watch. These can be equally important, as sometimes these low-value items have high margins.

Automating ABC inventory analysis

There is a way to overcome the shortfalls above and use ABC analysis effectively as part of your inventory management processes. The answer lies in utilising software to analyse and categorise your inventory. Some ERP systems offer basic ABC and XYZ analysis functionality. However, you should invest in an inventory optimisation tool for more advanced capabilities.

ERP apps like EazyStock take ABC inventory analysis to the next level. EazyStock carries out multi-dimensional item categorisation that considers a range of variables, including:

- Value of annual usage – sales volume x unit cost

- No of picks – number of times picked over the year

- Demand volume – number of units sold

- Sales frequency – what % of historical periods have a sale

The result is a far more advanced inventory classification matrix. EazyStock then uses it to recommend inventory policies, providing service level targets and safety stock levels for each product category down to SKU level.

As EazyStock recalculates and updates the classifications daily, it sends alerts when products move between categories. This keeps segmentation in line with market dynamics.

For more information on how EazyStock can deliver advanced ABC analysis functionality download our eGuide, where we deep dive into this topic.

With the analysis and hard work done for you, you can then manage by exception, focusing on the categories or even SKUs that EazyStock suggests need your attention.

Contact us today for a demo or to discuss your inventory challenges call: 0121 312 2992.

Post first published 10 July 2015, updated July 2021 and October 2023.