Seasonal demand forecasting (2025 Guide)

What is seasonal demand?

Seasonal demand is defined as a time series with repetitive or predictable patterns of demand, due to re-occurring seasonal events. These patterns can re-occur over days, weeks, months or quarters and often make it harder for businesses to accurately calculate demand forecasts.

Seasonal demand examples in the UK include religious festivals such as Christmas or Ramadan, annual events like Valentines Day or Bonfire Night and seasonal weather patterns, including snow in winter and a hot climate in summer.

Here’s how you can plan better for seasonal demand fluctuations and why doing so can improve your forecasting accuracy and optimise your competitiveness.

How to optimise your competitiveness by forecasting seasonal demand

Businesses that cannot accurately forecast seasonal demand often face issues with their stock levels. If they under-forecast this can cause stockouts and lost sales during times of peak demand. And if they over-forecast they can face being left with excess stock that needs to be sold off at the end of a season.

If you can therefore forecast for seasonal demand accurately, you can gain an advantage over your competition and revel in the benefits.

Take advantage of peaks in demand

Forecasting for seasonal variances will ensure you have sufficient levels of stock available to take advantage of increases in product demand at peak times of the year. If you rely on your busy seasons to make most of your money, you need to be on top of your game and ensure optimum product availability during these times.

Prevent excess stock levels

Equally, it’s important that you don’t over forecast for seasonal demand fluctuations. Instead you want to invest in the right amount of inventory to ensure your cashflow remains fluid and your balance sheet is healthy.

By preventing excess stock at the end of a season, you don’t face the dilemma of selling it off at a discounted rate or taking on the burden of inflated carrying costs until demand picks up again.

Keep suppliers informed and orders on time

It’s easy to forget the importance of preparing your suppliers for seasonal demand fluctuations. Smart businesses will work closely with their suppliers, giving them visibility of their needs with plenty of time to react. By planning orders upfront, your suppliers can help guarantee deliveries to meet customer demand.

Make informed stock decisions

With accurate demand forecasts that account for seasonality you can optimise stock levels and make informed decisions on safety stock levels and replenishment rules.

How to forecast for seasonal demand

There are four basic rules to forecasting seasonal demand:

1. Identify which products are affected by seasonal demand

It’s important to remember that seasonality only refers to the portion of demand fluctuation accounted for by a reoccurring pattern. Therefore, you only need to identify demand patterns that repeat systematically over time.

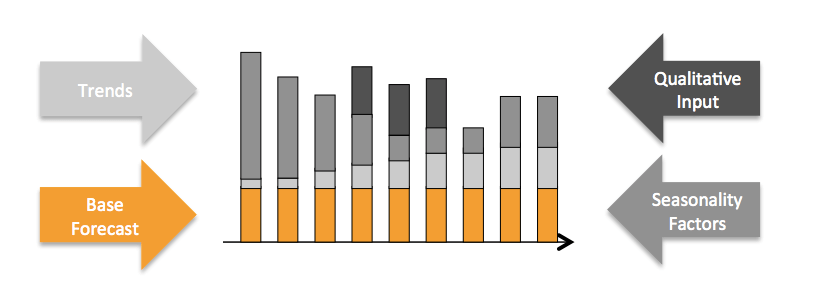

Below is an example of other demand factors that can impact or inflate your normal base demand.

When analysing seasonal demand for each stock item, be sure to ask the following questions:

- Can you see the same demand pattern year-on-year? Analyse the correlation between each year, if there’s an underlying pattern, you have a seasonal demand you can rely on.

- Are you sure the change in demand is a seasonal variance and not just a trend upwards/downwards over time? De-seasonalise the demand e.g ignore the seasonal demand trend and check whether the demand is still increasing.

- Is the seasonal demand strong enough to warrant treating the product differently? Analyse the amplitude of the variance.

2. Understand when the peaks will happen

This sounds obvious, it is! Use past demand data to calculate when upcoming peaks and troughs will occur. Read our tips on demand forecasting best practice.

3. Accurately forecast the relative size of those peaks compared to normal demand

If seasonality is relevant to an item, you should adjust the demand accordingly before using it in a forecast calculation. Best practice is to keep seasonal demand and other variable factors separated from your base demand calculations, in order to keep the data clean, and easy to use for forecasting going forward.

4. Understand the level of uncertainty associated with those forecasted peaks

Marketplaces are more dynamic than ever, so it’s rare for a demand forecast to be 100% accurate, especially when seasonality is part of the equation.

It’s therefore important to consider the accuracy of your forecast.

There are many techniques to improve the accuracy of your forecasts, such as identifying demand outliers and investigating their impact on your calculations.

In addition, working out forecast error will help you understand the level of error in your previous demand forecasts. You can then factor this into future ones and adjust stock rules, such as safety stock levels or re-order points, accordingly.

Make forecasting seasonal demand easier with EazyStock

If forecasting seasonal demand still feels like a tall order, perhaps you should consider investing in an inventory optimisation tool, such as EazyStock. With EazyStock you can save time and remove the hassle of manually calculating seasonality and forecasting demand. Instead EazyStock does all the hard work for you, providing up-to-date, accurate and detailed demand forecasts, that consider factors such as seasonality, trends, supplier lead times and delivery schedules.

If you find inventory forecasting a challenge, contact the EazyStock team today. Our demand forecasting software gives you advanced capabilities to speed-up day-to-day stock management tasks.