How to manage inventory effectively in a growing business

Inventory management, business growth and expanding product ranges

There are several reasons you could be expanding your product portfolios. Whether your customers demand more variety or you’ve strategically decided to diversify your product ranges, you could face some internal inventory management problems:

- Difficulty managing SKUs efficiently using spreadsheets or manual processes.

- Reducing stock levels to carry more lines (without accurate forecasting and inventory optimisation tools), which can lead to stockouts, expensive backorders, or rush orders.

- A build-up of excess inventory and obsolete stock as forecasting models fail to keep up with quickly changing social trends and technologies.

- Increased operational costs and a lack of warehouse space.

You must adapt your inventory management processes to manage stock effectively as you continue to grow. One way to do this is by implementing inventory optimisation practices to balance stock levels.

Inventory optimisation is critical to growing businesses with an extensive stock range. It starts with identifying the demand patterns of your products so you can then accurately forecast demand and optimise your stock to ensure order fulfilment.

Let’s look at each in more detail:

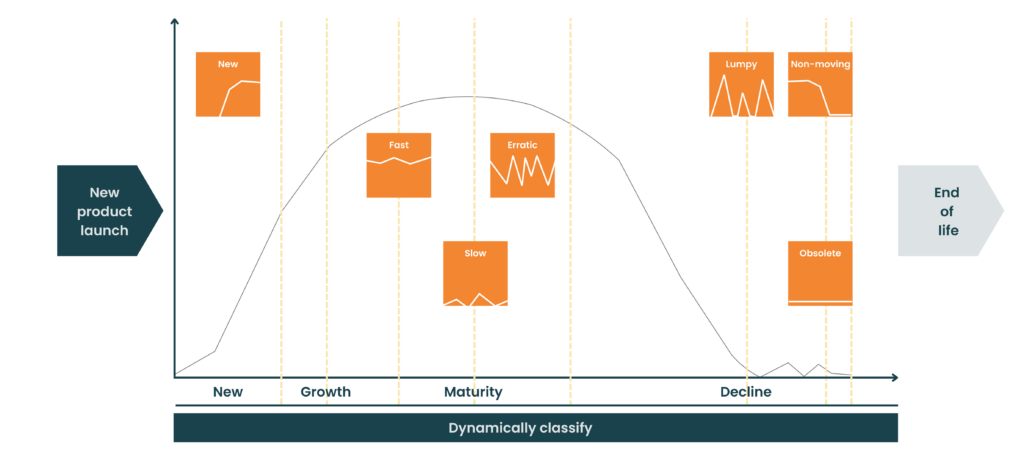

Identifying demand types

All products in your warehouse have a product lifecycle, which they will move through at different times and paces. At the growth stage, items will display either positive or ‘fast’ demand, i.e. selling a steady volume. As an item moves to maturity, demand may become ‘erratic’, with more unpredictable, fluctuating demand or an emerging negative demand pattern.

Identifying and tracking demand types will help you accurately forecast future orders and prioritise which products to stock.

Accurate demand forecasts for smart procurement

Accurate demand forecasting helps you achieve the right inventory levels to fulfil orders while preventing excess or obsolete stock risk. After all, tying up capital in excess stock increases opportunity costs, resulting in less cash to invest in new lines or react to opportunities.

When forecasting demand, ensure you consider demand variables, such as seasonality, trends and qualitative information sources to make demand forecasts as accurate as possible. If you’re looking for growth opportunities, you need to understand what your customers are buying now and in the future to generate demand forecasts.

Adjust your forecasting formula to consider the demand types above. Each demand type has a different deviation from its mean and, therefore, responds better to some forecasting algorithms than others. Our eGuide provides more guidance on accurate demand forecasting.

Optimising inventory levels as SKUs grow

Once you understand the items in demand, you need to carry enough stock to meet those forecasts.

As your company grows and you increase the number of SKUs you carry, finding valuable shelf space to carry new inventory can be a struggle. It’s tempting to reduce the quantities of each line to make space, but this can lead to supply chain problems. Unless your supplier lead times are short or you have drop shipping arrangements, cutting your stock levels can increase your risk of stockouts, affecting customer satisfaction.

Effective inventory management uses stocking policies and inventory classification to prioritise the stock you carry based on its value to the business. When setting stocking policies, the objective is to prioritise products forecasted to sell well in the future and make you the most money. You can then reduce the stock levels of other SKUs, preventing the likelihood of building up excess stock levels, which can turn obsolete.

ABC analysis is a simple way to categorise inventory. It helps you stock more category ‘A’ items that sell well with a good profit margin versus ‘C’ items with low sales rates and less value to the business.

With inventory planning software, stock classification can be much more advanced. For example, EazyStock bases stocking policies on several key criteria:

- Demand volatility – EazyStock automatically segments items based on their demand volatility and ease of demand forecast.

- The value and annual usage of each SKU – this accounts for sales volume and the product’s unit cost.

- Each SKU’s pick frequency – this distinguishes high-volume products with many requests (1000 requests for 1 unit) from high-volume products with low requests (2 requests for 500 units).

For example, suppose you wanted to focus on products with a high annual usage value. You could prioritise those with predictable demand patterns and high pick frequencies (as the risk of excess stock is low, and you need to ensure you can cover demand) over those with volatile demand and low pick frequencies (as these are expensive to stock with inconsistent demand).

Automated inventory management assists business expansion

Cloud-based inventory optimisation software, such as EazyStock, can be advantageous when managing a growing or extensive product portfolio, as it considers a range of inventory data. EazyStock is designed to automate demand forecasting, stocking policies and replenishment tasks to help you manage your stock more effectively.

It factors in supply and demand variables and dynamically adjusts inventory levels and reorder points to ensure stock availability for order fulfilment while optimising turnover. By removing spreadsheet reliance, you’ll reduce the risk of human error and speed up complex calculations.

Effective inventory management is critical to business growth

Effective stock management is critical if your business and product lines are constantly growing. Many small businesses have invested in inventory management systems, such as enterprise resource planning (ERP) or warehouse management systems (WMS). While these may be effective at inventory control processes, such as tracking and counting items in your warehouse, many lack the functionality to optimise your inventory levels.

Implementing inventory optimisation software rather than or as well as an inventory management solution can help overcome many inventory management problems growing businesses face. Its ability to carry out accurate forecasting, set cost-effective stock levels and automate reordering delivers a fast ROI for many businesses.

If you have inventory management problems that you’d like to discuss with our team, or you’d like a demo of EazyStock software, please get in touch.