How to improve stock management in Microsoft Dynamics 365

Dynamics 365 Business Central, or Business Central, is Microsoft’s newest ERP. Predominantly based on the functionality of Dynamics NAV, it seamlessly integrates with other Microsoft 365 software suite applications to provide a fully integrated business system. Dynamics Business Central has primarily been developed for the cloud as a scalable SaaS product, allowing businesses to pay per user, per month.

Dynamics BC and NAV are both known for their comprehensive functionality across a range of business operations, including finance, customer service, warehousing and logistics. Users can explore Microsoft’s AppSource marketplace to find additional applications with a wide range of more specialised functionality. EazyStock is one such add-on that helps customers who require more advanced inventory forecasting, planning and replenishment. In this post, we review Business Central’s inventory management capabilities and discuss what additional features and benefits EazyStock can offer.

Microsoft Dynamics 365 Business Central inventory management features

Microsoft Business Central’s inventory management functionality enables users to oversee the management of stock items across their business. It stores a wealth of data about all products and updates stock levels based on outgoing sales and incoming purchases.

Using Dynamics 365 Business Central inventory management, you can:

- Manage a wide range of data on every inventory item, including units of measurement, unit costs, sales prices, and dimensions.

- Group items into hierarchical structures and assign category attributes.

- Assign stock locations and track items from one location to another.

- Link items to create a bill of materials for production.

- Post sales and purchases against each item to adjust stock counts automatically.

- Link replacement articles to offer alternatives to sold-out products.

- Manage non-stocked items.

When are Microsoft Dynamics 365’s inventory management features not sufficient?

The complexity and importance of inventory management are often underestimated. Fundamentally, inventory planners have to calculate what to buy, when to buy it, and in what quantities, which is not as simple as it sounds.

For starters, forecasting encompasses many aspects, including seasonality, trends, promotional activity and allowing for forecasting error. When determining optimal order points and order quantities, buyers must keep track of various factors, including minimum order quantities, stock multiples and article replacements, while ensuring adequate storage space. Finally, they also need to manage supplier relationships and track and account for fluctuating lead times.

The Dynamics 365 Business Central inventory management functionality may be sufficient for businesses with a few product lines, relatively stable demand, a small number of suppliers and steady lead times. In such cases, manually creating forecasts and working out order quantities and safety stock levels is a manageable task. With larger or growing product ranges, high stock availability ambitions, many users find that they struggle to hit order fulfilment targets, prevent stock-outs and keep inventory investment under control.

Tell-tale signs that you need a more advanced tool for inventory management:

Here are eight signs that you need to improve the capabilities of Microsoft Business Central inventory management:

- Inaccurate demand forecasts

- Static inventory turnover rates

- Lost sales from struggling to improve service levels (stock availability/order fulfilment)

- Consistently tying up too much working capital in excess stock

- Issues with obsolete stock and dead stock

- Losing time updating Business Central’s reordering policies and planning parameters

- Regular stockouts or incomplete orders that lead to unhappy customers

- An inability to deal with irregular supplier lead times

Here’s how an inventory optimisation tool can help fill the void.

How does EazyStock complement Dynamics 365 Business Central inventory management?

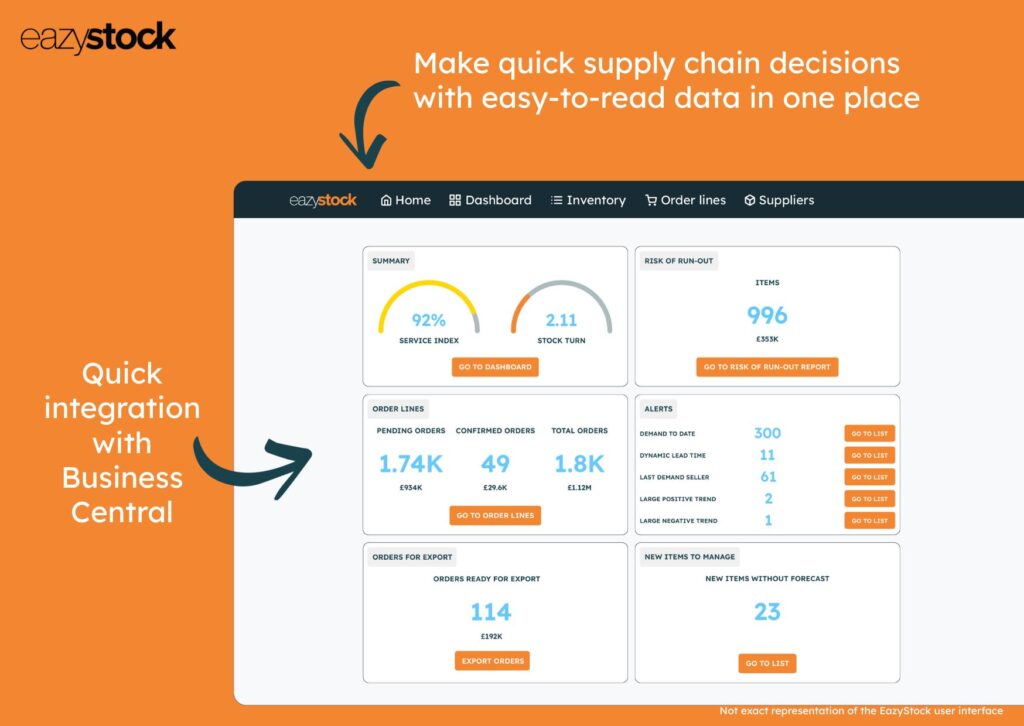

EazyStock is an ERP add-on, specifically designed to provide organisations with inventory optimisation capabilities. As a cloud-based tool, EazyStock easily integrates with Dynamics BC via a ready-made connector, making it simple to implement with fast ROI.

Key benefits of inventory optimisation include:

- Statistical demand forecasting over manual forecasting

- Advanced inventory classification

- Optimised stock levels

- Automated reordering and replenishment

Demand forecasting

Like many ERPs, the demand forecasting functionality in Dynamics BC relies on users manually uploading forecasts and combining them with relevant reordering policies. The system then suggests a reorder proposal when stock levels are insufficient to cover demand.

Anyone who manually produces demand forecasts using spreadsheets knows that this is a resource-intensive task that requires regular review to ensure forecasting accuracy.

Additionally, if you are calculating demand for items with erratic or inconsistent demand using previous demand data alone, you’ll experience forecasting errors.

Finally, forecasting using only spreadsheets makes accounting for seasonality, long-term demand trends, and promotional activity challenging.

EazyStock automates demand forecasting and brings advanced functionality. The software analyses historical demand data and classifies each inventory item into one of eight different demand types, depending on the item’s position in its product life cycle. EazyStock uses the demand type to determine the statistical algorithm it uses to calculate each forecast.

EazyStock also identifies factors such as seasonality, consumer behaviour trends and promotions, and adjusts forecasts accordingly. You can also configure EazyStock to weight forecasts on more recent demand data (for fast-moving industries) or longer historical demand periods (for slow-moving industries).

Inventory classification and stocking policies

Microsoft encourages Dynamics BC users to manually categorise their stock items using a simple ABC analysis model. This model is based on an item’s value and volume relative to total stock. So, high-value, low-stock ‘A’ items are treated differently from low-value, high-volume ‘C’ items.

Users should then use this information to choose and assign a suitable reordering policy to each item within their ERP – another time-consuming manual process.

Unfortunately, as soon as the information is entered, it will begin to become outdated, leading to the assignment of unsuitable reordering policies to items and, consequently, stockouts or excess stock.

As EazyStock automates inventory classification, it can go beyond simple ABC analysis. It divides stock items into more granular categories based on criteria including demand type, value of annual usage (VAU), pick frequency and demand volatility. With every SKU categorised into an inventory matrix, EazyStock applies specific stocking rules to each group.

This means that you can make much more informed, data-led stocking decisions than when using a simple ABC analysis framework.

Working with service levels

Many businesses use service level KPIs to measure stock availability or order fulfilment.

Unfortunately, most ERPs, including Dynamics Business Central, lack the functionality to measure and track this important KPI. With EazyStock, however, target service levels can be set and measured at product group or even SKU level, allowing businesses to monitor stock availability more closely. Dynamic inventory classification and stocking policies aim to achieve target service levels with the minimum amount of stock.

Automated order proposals

When it comes to reordering functionality, Dynamics 365 Business Central’s inventory planning module undoubtedly has more sophisticated features than many other business systems on the market.

Users can manually enter a range of planning parameters for each stock item, such as reorder points, safety stock lead times, safety stock quantities, time buckets (reorder cycles), and order modifiers, e.g. min/max order quantities. They can then assign one of four reordering policies to each stock item, which determines how these individual planning parameters interact, ultimately calculating when and how much to reorder.

However, this places relatively high demands on the user, who must first determine the best reordering policy for each item and then manually calculate a whole range of parameters outside the system. Many of these parameters may also need continual recalculation and updates to prevent them from becoming outdated.

In contrast, EazyStock calculates all orders automatically and continuously adjusts all inventory parameters based on demand forecasts, inventory policies, service level targets and supplier lead times. This means that reordering becomes market-driven, and responding to customer behaviour (or production requirements) and suppliers’ capacity.

EazyStock can also adjust reordering based on any additional ordering constraints you or your suppliers have. For example, you may only have the resources to reorder on certain days of the month or receive deliveries on certain days of the week. Alternatively, your suppliers may have specific periods during which production slows or shuts down, such as the Chinese New Year or summer holidays. EazyStock automatically adjusts reordering quantities, dates and safety stock levels to help optimise stock levels and prevent stock-outs.

This means that users receive a continually optimised list of order proposals, which they can then decide to review orders or automate the ordering process. The orders can then be pushed back into Business Central for processing.

Improve inventory management with Dynamics Business Central and EazyStock

EazyStock is an invaluable add-on to Business Central that enables inventory management teams to shift their focus from manually producing forecasts and updating reordering policies to reviewing those automatically generated by the software. This means more time to devote to strategic tasks, such as managing customers and overcoming supply chain challenges

At the same time, the powerful stock optimisation tool will deliver impressive results, lowering inventory levels by 30% or more, releasing capital and improving stock availability.

If you’re interested in finding out more about our Business Central connector, or how inventory optimisation software could help your business, email us or call 0121 312 2992.

You can read more about the benefits of connecting EazyStock to Business Central and how the connector works in our free eGuide – Enhancing the inventory management capabilities of Microsoft Dynamics 365 Business Central.