Understanding minimum order quantity (MOQ) and its issues

What is an MOQ, and how do you overcome its challenges?

ABC, ERP, EOQ, JIT…acronyms are everywhere in inventory and supply chain management, including MOQ. So what does MOQ mean?

MOQ stands for minimum order quantity. It is the lowest amount a supplier will accept for an order, which can be units, value, or weight. MOQs can be for single items or a range of items.

Suppliers might need to set up a production run that will produce a certain quantity, so they don’t want to have waste or costly extra stock that they can’t sell. MOQs vary depending on product, supplier and industry, but they are common in manufacturing and wholesale businesses.

Suppliers use MOQs as it’s more cost-effective and increases their sales margin. If your supplier is trying to remain competitive by selling products with minimal markup, selling low quantities could see them losing money. The minimum order quantity helps them to ensure they are at least breaking even on their orders.

MOQs and their impact on inventory

Minimum order quantities, values, and weights are common challenges for inventory planners and purchasers. If you only have one supplier of a particular item, you will be bound by their MOQ, meaning you might need to order more stock than you need. Whereas, if you have multiple suppliers of the same product, they might have different MOQs, so you need to determine which is the best to meet your needs.

Suppliers with high MOQs could see you increase your average inventory levels, which has a knock-on effect of increasing holding costs. This also ties up working capital and increases the risk of excess stock becoming obsolete. You can read more about managing excess stock in our blog post.

However, high MOQs can be beneficial because they can reduce administration and ordering costs, as you won’t need to send as many orders. Buying in bulk usually brings cost savings as you will get a lower unit cost. You also reduce the risk of stockouts, as you’ll have excess stock.

Lower MOQs allow you to hold lower inventory levels, reduce working capital tied up in stock, and reduce the risk of stock becoming obsolete or dead stock.

Conversely, you might need to place more orders or carry safety or buffer stock.

This means that when purchasing from suppliers, it’s essential to understand the impact their MOQ could have on your inventory levels. You should always aim to find the optimal level of inventory where you have enough stock to meet demand, with some safety or buffer stock, but you aren’t investing capital in unnecessary excess stock that could become obsolete.

For example, you need to create an order for item A to send to your main supplier but realise that you’re below their minimum order quantity.

You add more of item A, and even though there’s no forecasted demand, order some of item B to bump up your quota and then top off the order with some of item C to hit the magic MOQ number.

On the plus side, you’ve hit the minimum order requirement and ordered the all-important A items you need. However, you now have unnecessary stock of items B and C taking up space in your warehouse and tying up working capital.

To make things worse, when your ordering window rolls around the following week, you realise that you need to go back to that supplier and place an order for item D – starting the process over again!

So how do you find the balance between the MOQ and the quantity you actually need?

Using software to overcome MOQ inventory challenges

EazyStock is an automated inventory optimisation tool that ensures you carry the right stock, in the right quantities, in the right locations, at the right time. EazyStock constantly analyses all your SKUs based on their demand and supply characteristics, including their demand pattern and volatility, pick frequency, cost to sell and supplier lead times. The system then calculates which items to stock and produces daily replenishment recommendations.

EazyStock also calculates your unconstrained order quantity, which is the amount you’d order if there were no MOQs. This means you can negotiate with the supplier or look for one whose MOQs actually align with your needs, making it easier to balance stock levels and capital expenditure.

EazyStock’s order fill-up functionality to support

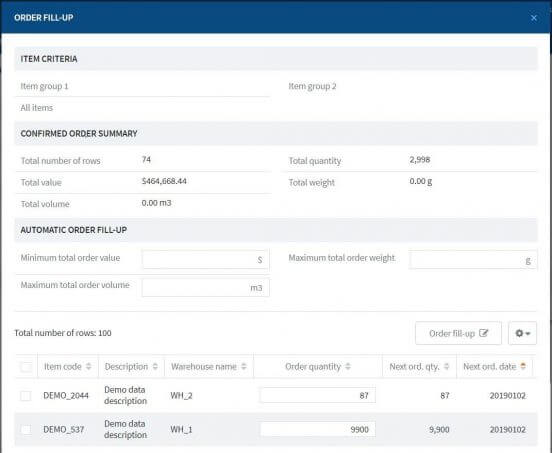

EazyStock’s order fill-up functionality helps inventory teams cost-effectively meet their suppliers’ contractual minimum order quantities, values, or weights. The exclusive functionality is designed to only order stock with a future forecasted demand, keeping excess stock under control.

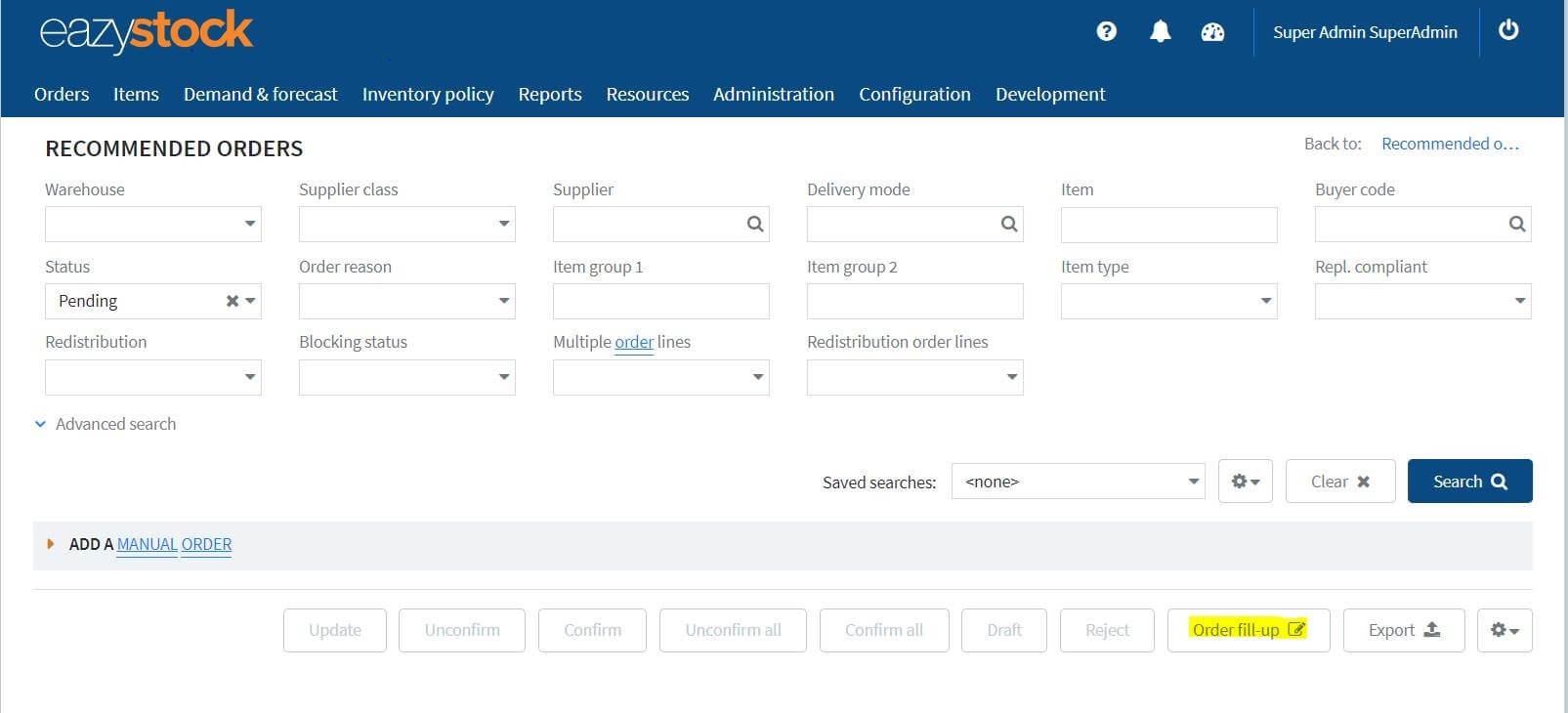

The functionality kicks in when you’re placing a supplier order and find that you’re short of your minimum order quantity, value or weight. Once you confirm your initial order lines, you can go to that supplier’s profile in EazyStock and click “order fill-up”.

From there, you’ll get a complete list of the SKUs from that supplier, along with the upcoming recommended orders. You can fill out the supplier’s order value, volume, or weight, and EazyStock will identify items with upcoming demand that you should order to meet the required amount.

If you’re happy with the recommended orders, click “create order lines” and either send the request to your ERP to produce a purchase order or straight to your supplier. This allows you to remove the need for manual random selection or guesswork and only order necessary stock instead of items that could tie up capital as excess or obsolete stock.

Removing minimum order quantity (MOQ) frustrations

Using our previous example, EazyStock would have identified the future demand for item D and pulled the order forward instead of filling the order with items A, B, and C.

EazyStock users save a lot of money by ordering items they will need (either now or soon) and not tying up capital in excess stock. Plus, filling up an order with items with upcoming demand minimises the number of orders needed with suppliers – saving even more money.

Inventory planners or purchasers will also be more efficient and save time that would otherwise be wasted by combing through SKUs and determining how to reach an MOQ or cube out a container.

So, with fewer orders, increased inventory accuracy, less excess stock, more working capital and improved efficiency, it’s easy to understand why the order fill-up functionality is a firm favourite with many EazyStock users.

Want to learn more? Please contact us for a demo or call us on 0121 312 2992.

Last updated: 01/03/2023