A review of Business Central’s inventory planning and reordering policies

As any inventory manager will tell you, it doesn’t matter how sophisticated their ERP software is. They still have to use spreadsheets to manually set reordering parameters and then input the information back into their system so it can inform purchasing decisions.

Unfortunately, Microsoft Dynamics 365 Business Central is no different. Whilst the market-leading ERP for small and mid-sized companies arguably has more advanced reordering capabilities, users still have to do a lot of manual calculations.

In this post, we’ll examine the inventory ordering functionality in Microsoft Dynamics 365 Business Central/NAV and explain how EazyStock can deliver additional capabilities.

EazyStock is an established inventory optimisation app available in Microsoft Appsource. With our ready-made connector, it’s easier than ever to integrate EazyStock with Business Central to provide advanced inventory management capabilities. In previous posts, we’ve looked at demand forecasting and inventory classification. Here’s an overview of its replenishment features.

Microsoft Dynamics 365 Business Central’s reordering policies

In Dynamics 365 Business Central’s inventory management module, users can manually enter a range of planning parameters for every stock item. These parameters include reorder points, safety stock lead times, safety stock quantities, time buckets (reorder cycles), and order modifiers, e.g., min/max order quantities or order multiples.

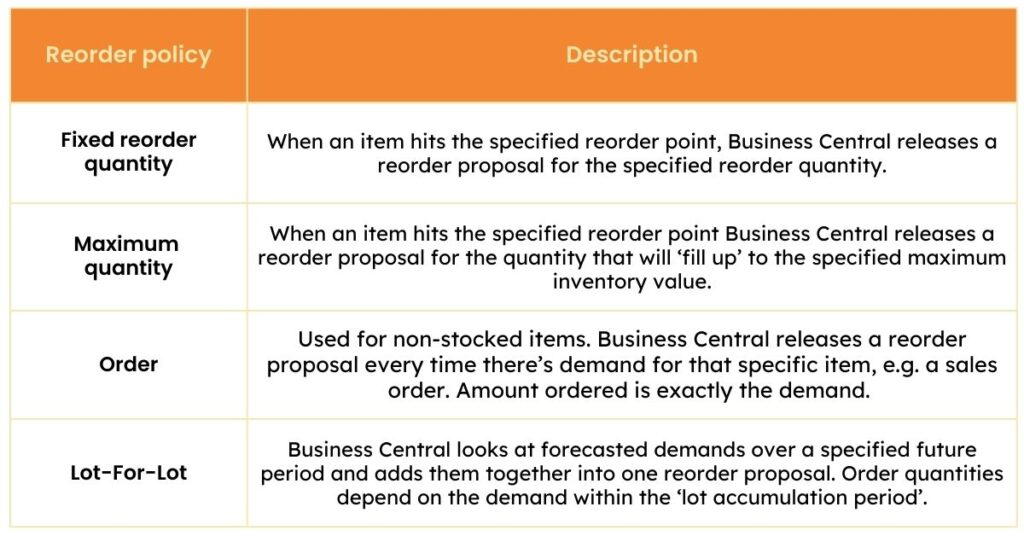

You can then assign one of four reordering policies: Fixed Reorder Quantity, Maximum Quantity, Lot-For-Lot and Order.

Your chosen reordering policy determines how the individual planning parameters interact and how the ERP calculates when to reorder and how much to reorder. Using this pre-programmed logic, Business Central produces reorder proposals when replenishment is necessary.

Whilst this functionality is more advanced than many ERPs, it still has a number of crucial drawbacks:

- It’s time-consuming to set-up e.g you need to calculate all planning parameters outside of Business Central and port them back in.

- It relies on you knowing which reordering policy is most suited to every stock item.

- Some reordering policies are dependent on manual demand forecasts; some don’t even use forecasts.

- Every planning parameter and reordering policy is static and has to be manually adjusted.

- It relies on lead times remaining static.

- Planning parameters are interlinked. For example, safety stock is dependent on lead times and demand volatility. Min/max order quantities can affect reorder points and quantities. This means that when one parameter requires adjustment, they all might.

The lack of automation around allocating the reordering policies and planning parameters makes replenishment a very time-consuming and manual process for the user. Plus, most markets experience fluctuating demand and supply variables. This means these policies and parameters need to be regularly revised to prevent reordering resulting in episodes of excess (even obsolete) inventory or stockouts.

Automated reordering and replenishment

A key benefit of using EazyStock is that it removes all the manual work and deliberation over choosing the right replenishment strategies and rules.

EazyStock calculates all reordering policies and automatically adjusts them to changes in demand forecasts, stocking rules, target service levels and supplier lead times. This means reordering becomes market-led and reacts to customer behaviour (or production requirements) and supplier performance.

Let’s look at some examples of EazyStock’s replenishment functionality:

Safety stock

Most inventory planners manually calculate safety stock quantities by taking the cycle stock quantity over a specified period and adding a little more, just in case.

In comparison, EazyStock uses statistical algorithms to consider important factors, such as service level, forecast accuracy, and lead time variability. Since each inventory item has a unique demand pattern, it adjusts safety stock levels accordingly.

Reorder alerts

In Business Central reorder points are either a fixed amount or based on a static forecast –both of which are manually calculated.

In contrast, EazyStock automatically factors in dynamic demand forecasts (so ordering mirrors customer demand), safety stock levels (so stockouts can be avoided) and supplier lead times (so supplier holidays or busy periods are covered).

If ordering or delivery acceptance can only take place on specific days of the week or month, you can add these operational constraints to EazyStock’s order calendar feature. The system then recalculates reorder quantities and safety stock levels to prevent any impact on stock availability.

Reorder quantities

In Business Central, reorder quantities are either a specified fixed amount (using the Fixed Reorder Quantity reordering policy), vary to hit a specified max/min capacity (Maximum Order Quantity), or are accumulated based on a demand forecast (Lot-For-Lot).

All options have the potential to result in stockouts or holding surplus stock. For example, fixed or maximum order quantities are static and fail to account for market dynamics. The Lot-For-Lot strategy relies on a manual forecast and places the order when the first demand is needed, so unless the lot accumulation period is relatively short, items could be held in the warehouse for unnecessarily long periods of time.

Instead, EazyStock automatically generates daily order proposals where the order quantity is calculated based on current stock levels, reserved stock, goods-in-transit and back-orders, dynamic demand forecasts and stocking rules, as well as planning parameters, e.g safety stock, min/max order quantities, etc, so the optimal reorder quantity is always suggested.

Lead times

EazyStock’s dynamic lead time feature helps mitigate the impact of supply delays on fulfilment. It does this by tracking actual lead times and sending alerts when they begin to deviate from the norm. Users can then either manually adjust planning parameters for the affected items, or let the system update them automatically.

Smart and efficient reordering

In previous posts, we’ve examined how EazyStock forecasts demand and classifies inventory before assigning stocking policies to each individual stock item.

The system then continuously analyses items to ensure each one falls into the correct demand type and the appropriate area of its inventory matrix, so it’s subject to the correct stocking rules and the replenishment parameters discussed above are adjusted accordingly.

With these advanced algorithms working in the background, EazyStock provides a daily list of items and their optimal reorder quantities. Users can then decide whether to review the orders (which they may do for high-priority, slow-moving items) or simply automate the ordering process (which often happens with faster-moving, low-value items where the risk of excess stock is low). The orders can then be imported back into Business Central for processing.

Finally, by reviewing EazyStock’s user-friendly dashboard daily, users can sense-check their replenishment recommendations. The system promotes managing by exception, providing inventory alert reports so attention can be given to product categories or even SKUs that need revision or fine-tuning from a human perspective.

The result is that day-to-day replenishment tasks become more efficient, with reordering that takes account of demand and supply variability and prevents over-stocking.

Supply chains are more complex than ever and inventory management teams have many plates to spin in terms of dealing with erratic demand and unpredictable supplier lead times. The less time they need to spend on stock calculations, the better. With EazyStock, planners can save valuable time and resources by automating forecasting and replenishment calculations. With a wealth of accurate and drillable data to hand, they can also make better purchasing decisions, making them more able to respond to changes in demand or supply.

If you’d like to know more about how EazyStock can support your inventory management operations, please get in touch with our team today.