5 steps to reduce excess and obsolete inventory in 2024

If you type ‘excess inventory’ or ‘obsolete inventory’ into any search engine, you’ll find a wealth of companies offering to buy your surplus stock items. You might get an instant cash injection and free up warehouse space – but at what cost? Excess inventory has many disadvantages, including the risk of it becoming obsolete. Selling excess inventory items at a discount quickly reduces your stock levels and alleviates cash problems but can hurt your profit margins.

In this post, we look at proactive inventory management measures you can take to reduce excess and obsolete inventory in your business.

Identify your excess and obsolete inventory

Try to categorise your stock into three categories:

Healthy inventory (cycle stock): This is the inventory you plan to sell based on demand forecasts.

Excess inventory: When stock levels for a product plus buffer stock exceed forecasted demand.

Obsolete inventory: When stock remains in the warehouse without demand for a prolonged period (typically at least 12 months).

This information is a great starting point to understand if you have a problem with excess and obsolete inventory.

Evaluate whether the excess inventory is ‘risky’ (could become obsolete)

Sometimes, it’s OK to have higher levels of stock than demand requires. For example, when you have high volumes of fast-moving items that continuously sell well. You can easily lower current stock levels by reducing reordering levels and using the surplus.

However, excess stock becomes a risk when you have high volumes of items sitting in your warehouse that are slow-moving or have volatile demand, e.g. periods of low or no sales, or have declining demand, i.e. they are coming to the end of their product life cycle. You, therefore, need to identify these items and plan how to reduce their stock levels and prevent obsolescence.

Understand the causes of your excess and obsolete inventory

There can be many reasons why you have excess inventory. Often it’s down to:

1. Poor demand forecasting capabilities

2. Needing to mitigate supply risks, e.g. regularly inconsistent supplier lead times

3. Striving for 100% stock availability (service levels)

4. A complex supply chain (this could be multi-tier (echelon) or multi-site)

5. Bad inventory management decisions

Use these rules as proactive strategies to help prevent excess and obsolete inventory

Rule one: Prevent excess inventory with better demand forecasting

If your demand forecasting regularly leads to over or under stocking, it’s time to look at ways to improve it. Some methods, such as predicting future demand based on the number of stock days are over-simplistic and inadequate. To forecast demand accurately, you need to consider moving to demand forecasting techniques that account for demand trends, seasonality and promotional activity.

Statistical demand forecasting carried out by inventory optimisation software, such as EazyStock, analyses every product in your portfolio and assigns a demand type according to its product life cycle position. This allows it to use the most relevant algorithm o forecast demand.

This means that as products move through the growth, maturity and decline stages and their demand patterns change, the algorithms used to calculate demand will dynamically update to maintain accurate forecasts.

Read more on demand forecasting accuracy or EazyStock’s demand forecasting software.

Rule two: Don’t use excess stock to mitigate supply risks

Carrying excess stock is not the answer to alleviating issues with your supplier lead times. Instead you need to address this problem by:

Planning for supplier holidays in advance: If you know when your suppliers shut down, e.g. for annual holidays, Chinese New Year etc, add these periods of closure to your lead times and adjust reordering points accordingly. Inventory optimisation software like EazyStock can make this easier by automating recommended orders.

Monitoring supplier lead times: Keep track of your suppliers’ lead times to understand if they are meeting their service level agreements. If they are consistently late, you need to speak to them to get back on track or find alternative suppliers. In the meantime, add adequate safety stock, (buffer stock) to your inventory to cover delays.

Read our post on effective inventory replenishment for more information on managing supply and demand variables to reduce excess inventory.

Rule three: Stop carrying excess inventory to prevent stockouts

The biggest takeaway from this post is that holding lots of stock isn’t the only way to ensure product availability. You can have high service levels and achieve excellent stock availability without carrying high volumes of every item in your warehouse. The key is to use inventory optimisation techniques when setting your stocking policies.

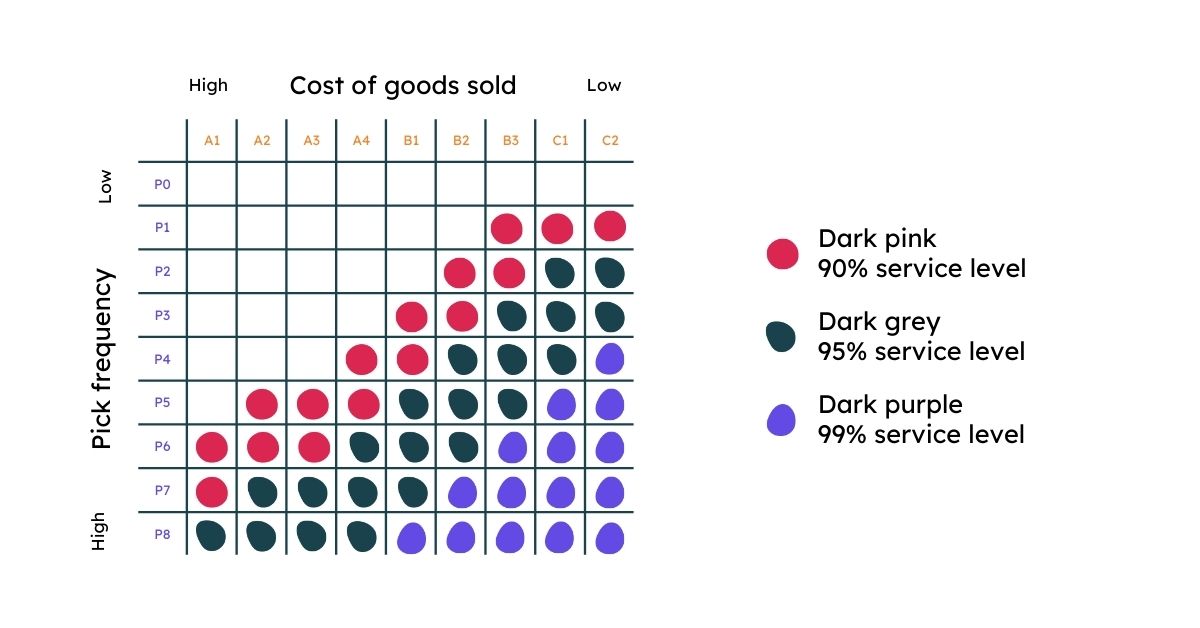

This means going beyond simple ABC analysis. Instead you need to prioritise which inventory items to carry based on multi-dimensional criteria, such as demand types, pick frequency, demand volatility and cost to sell (or profitability). This allows you to set the stock levels of every item in your warehouse according to how well it sells and how much it costs the business. A typical inventory policy matrix may look something like this:

Here, the dark purple items in the bottom right categories are picked most frequently and are cheap to sell. These are usually stocked in greater quantities than the dark pink circles, which are are picked less and are more expensive to the business.

Every company’s inventory matrix will look different (you can have more than one for different product categories). For example, a catalogue business may wish to stock all items and would, therefore, have all boxes shaded to some degree.

You should set a service level (stock availability) target for each category. Typically, these would be higher for products picked more frequently with a lower selling cost. The aim is to balance capital invested in stock with your ideal availability targets.

With stocking policies for every SKU that define individual stock levels and associated fulfilment targets, you dramatically reduce the risk of excess and obsolete inventory.

Creating an inventory matrix with this much detail could be challenging without inventory optimisation software. A tool such as EazyStock will undertake all the hard work for you. As demand, pick frequency and costs change, EazyStock will automatically move inventory from box to box, dynamically adjusting recommended stocking levels.

Rule four: Optimise inventory levels along your supply chain

If you have a multi-tier (multi-echelon) supply chain or carry stock across multiple locations it can be hard to prevent a build-up of excess inventory. For example, if you have decentralised ordering, it’s common for inventory planners to order ‘a little extra’ and inflate their forecasts to cover the risk of run-out. These ‘little extras’ will amount to high surplus stock levels if you do this across each stock location.

The answer is to plan and manage inventory with one centralised view. Systems like EazyStock base forecasting and reordering on point-of-sale demand data, not demand at each stage of the supply chain. A view of stock levels across all locations can balance out inventory. This means you can redistribute excess stock from one location to other sites with low levels of the same item before needing to order more from the supplier.

By managing your inventory across all echelons, or locations, you’ll quickly remove surplus stock from your supply chain and minimise the risk of obsolete items appearing on warehouse shelves.

Rule five: Buy stock wisely

It’s tempting to buy in bulk for the best price on an order, especially for fast-moving items. However, for slower-moving items with erratic or declining demand, it can cause problems. While you might save money on the inventory cost, if the items don’t sell, you’ll tie up capital in excess stock, risk obsolescence and the need to sell at a discounted rate.

Excess inventory could also result from high your minimum order quantities (MOQs). If this is the case, see if you can renegotiate with your suppliers or find alternatives with lower MOQs. It may be better to pay a higher unit rate for smaller order quantities, than have cash tied up in stock that isn’t moving through the warehouse fast enough.

Summary

Excess and obsolete inventory can be very problematic to businesses, and finding proactive ways to prevent stock build-up can bring significant benefits. Continuous improvement of cash flow, more working capital, a better inventory turnover ratio and lower storage costs all help ensure a healthy profit margin.

If you’d like to understand how EazyStock can help reduce the risk of excess and obsolete inventory in your business, contact us here or call 0121 312 2992.