How to deal with excess stock

Excess stock, regardless of a company’s efficiency and stock control, can accumulate in the warehouse. This surplus not only occupies valuable space but also triggers cash flow issues, potentially impacting your company’s bottom line.

What is excess stock?

Excess stock, a term familiar to many in the inventory management field, refers to when inventory levels exceed forecasted demand. Excess stock is also known as overstock, stock surplus, excessive stock, or excess inventory. This common challenge can constantly threaten your company’s bottom line.

Common causes of excess stock

Three culprits typically cause excess stock levels:

- Inaccurate demand forecasting

- Poor inventory replenishment tactics

- Lack of product life cycle tracking

1. Excess stock due to inaccurate demand forecasting

Items will accumulate on warehouse shelves if you over-forecast market demand and order more inventory than you’re likely to sell. Therefore, it’s crucial to strive for accurate demand forecasts. This involves identifying items with seasonality and upward or downward trends and adjusting the forecasts accordingly.

Your demand forecasts should also consider external factors, such as competitor activity. For example, if your competitors drop their prices or launch a new product, this could reduce demand for your products.

2. Poor inventory replenishment tactics and excess stock

Inventory replenishment involves ordering the right amount of stock at the right time to meet forecasted demand. Poor replenishment is often due to manual processes that don’t consider key information, such as current stock levels, supplier lead times and the wider supply chain, stage in the product lifecycle, and value of items to the business.

Your enterprise resource planning (ERP) or inventory management system might not have the functionality to continuously adjust your reordering points and quantities in line with supply and demand variables.

However, with the right specialist inventory optimisation software connected to your ERP, you can automate your inventory replenishment and consider all these factors. This automation not only speeds up calculations but also eliminates the potential for human errors and a build-up of excess stock, so you remain in control of your inventory management.

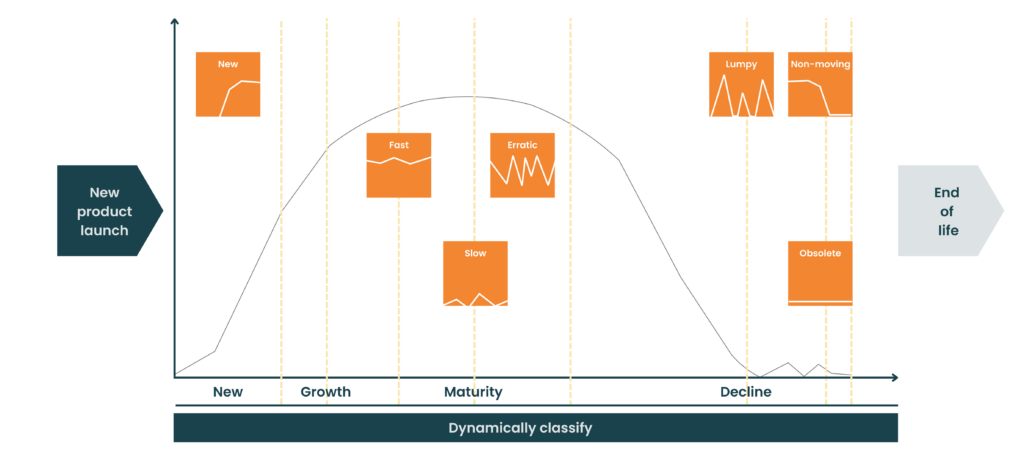

3. Excess stock management and the product life cycle

All products go through a life cycle – from market introduction through maturity to decline. Excess inventory often occurs during the declining stage of the product lifecycle, as demand begins to phase out. If you fail to spot this, you’ll continue to order based on previous demand patterns.

If you can’t or aren’t actively monitoring the demand stages of your SKUs, you risk getting stuck with a lot of excess stock due to inaccurate forecasting.

In the best-case scenario, a company can hope to sell off most of the excess stock and break even on their investment or only lose a small percentage of profit. However, if excess stock is not liquidated, it typically transitions to obsolete or dead stock, usually leading to a large and painful expense on the books.

Common misconceptions of excess stock

Businesses can sometimes falsely believe that excess stock is beneficial. Here are some common misconceptions:

“Excess stock is an efficient way to achieve higher service levels (order fill rates)”

Always having inventory on hand might seem like a logical way of having products ready to fulfil sales opportunities. However, while you might be able to meet all your orders, you’re tying up capital that could be invested in other areas of the business and reducing stock turnover. It could also cost you more, as it risks becoming obsolete or dead stock and needing to be disposed of.

Classifying your items by their value to the business allows you to hold sufficient levels to meet demand without hurting your bottom line. Rather than holding the same quantities of all SKUs, you can manage inventory levels by the importance of the items to your business.

Inventory optimisation is the process of achieving low inventory levels while maintaining high service levels. It is more efficient than holding uncapped quantities of each item.

“Excess stock allows higher safety stock levels (buffer stock)”

It’s easy to confuse excess stock with safety stock, but they are different. Safety stock is a strategic and calculated stock level that helps reduce the risk of stockouts due to unknown situations. Safety stock is included in the reorder point formula to account for variables such as supplier lead times or demand fluctuations. Effective safety stock levels ensure there’s always inventory available to meet sales demands and keep customers happy.

You should adjust safety stock levels based on demand forecasts, seasonality variances, trends, supplier lead times and a product’s place in its life cycle to ensure you won’t be left with excess stock. Inventory optimisation software like EazyStock can automate safety stock calculations to improve their accuracy and avoid excess stock.

“It’s worth having excess stock for bulk purchase savings”

Sometimes, purchasing in bulk quantities can indeed result in cost savings. It can also reduce shipping costs, e.g. one large order is cheaper than adding up shipping and handling costs from multiple smaller batch orders. However, committing to large quantities of items without considering demand is risky.

Intelligent demand forecasts and strategically optimised replenishment processes will see greater cost efficiencies without the burden of excess stock. The key is to find the optimal order time and quantity to ensure a continuous inventory balance to meet demand with stock piling up.

Our whitepaper on replenishment explains how to set the most cost-effective reordering times and quantities.

Disadvantages of excess stock

Carrying excess stock levels has many negative implications; we explain the top three below.

- High opportunity costs: Holding excessive inventory ties up business funds that could be invested in other areas, such as research and development or marketing. The inventory cost is not recouped until it is sold, and the longer this takes, the longer working capital remains unavailable. Consider the opportunity cost if the items are never sold.

- Increased carrying costs: The cost of warehousing can include the warehouse space, utilities and storage space maintenance. Some stock may also require additional maintenance, such as temperature control, to preserve the quality of the material. Excess stock of slow-moving products eats up warehouse space that could hold higher-demand products instead. You can reduce inventory levels by up to 30% by simply improving forecasting methods and replenishment practices.

- Quality reduction and product degradation: Storing items for longer than anticipated can lead to quality problems. In these situations, you may need to sell off stock at a reduced price or purchase new materials as replacements – both of which can be costly.

How to get rid of excess stock

If you have excess stock, there are ways you can reduce it. Once you do, it’s vital you put the right processes in place to ensure it doesn’t build up again.

- Discounts and sales. This is the most common option. We regularly see flash sales and promotions at the end of seasons as companies prepare for new products. If your margins are low, you might lose some of your initial investment, but it’s better than writing off the items completely.

- Remarket products. If your stock doesn’t have demand for its initial purpose or customer profile, could it work for an alternative industry or market?

- Product bundles. Similar to discounting, can you bundle items to make them more attractive to your customers?

- Return stock to suppliers. Ask your suppliers if they have a buy-back option or a way of returning items for a discount on future purchases.

- Liquidation companies. You could find a company willing to buy all your excess stock, and although this is likely to be heavily discounted, you can clear space in your warehouse.

- Write off or donate. If you cannot sell excess stock, you might have to write it off and take the financial hit.

- Donate or recycle. If it’s feasible, you could donate stock or look for industrial recycling options to avoid it going to landfill.

Do I have excess stock?

If your warehouse is bursting at the seams, and you can’t get new stock in, it’s safe to assume you have excess stock. However, if you aren’t sure if you have excess stock, you need to analyse your stock and categorise it into one of these three categories:

Cycle stock (health stock): The inventory you plan to sell, based on demand forecasts.

Excess stock: Stock above cycle stock and safety stock levels that exceeds forecasted demand.

Obsolete or dead stock: Stock that remains in the warehouse without demand (typically for at least 12 months).

Understanding the status of your inventory provides an initial insight into its health. Ideally, you should only purposefully carry cycle stock or ‘healthy’ inventory items to meet customer demand.

At EazyStock, we offer a free stock health analysis service. Our software will analyse your current stock levels and provide valuable, actionable recommendations for improving them.

Excess stock management solutions

Interested in learning how to drive down excess stock levels without the risk of stockouts? Contact EazyStock and schedule a demo to discover our excess stock management solution that will reduce inventory costs while increasing performance and profitability.