The ultimate guide to managing supply chain disruption

What is supply chain disruption?

As globalisation encourages supplier networks to extend across the world, the likelihood of supply chain disruption increases. Supply chain disruption is when events, sometimes planned, sometimes unpredictable, affect the supply of inventory. Often, if not dealt with effectively, it can make it challenging to fullfil orders on time and, as a result, can lead to stockouts.

In this post we’ll take a look at some of the top causes of supply chain disruption, the impact they have on your business and how this can be mitigated.

Types of supply chain disruption

Disruptions to your supply chain can happen for many reasons. Sometimes the delays are totally out of your hands, but other times they may be preventable.

Holidays

Holiday seasons can often affect supply, bringing manufacturing and distribution to a standstill. Companies sourcing goods from China experience this every year. Chinese New Year marks a two to four week period when production shuts down for workers to travel home for the festivities. Some European countries, such as Italy, also shutdown for long periods over the summer.

Black Swan events

A black swan event is an unexpected event with severe consequences, like the Great Recession or the current coronavirus pandemic. There’s no denying the massive impact that the pandemic has had on supply chains around the world, affecting the creation, shipping, movement of and demand for goods.

Natural disasters

Natural disasters such as earthquakes, hurricanes, wildfires and floods can have far-reaching effects down the supply chain. Even localised events can result in delayed or cancelled deliveries, closed ports and drastically unbalanced supply and/or demand.

Transportation and delivery failures

Transportation failures are a major byproduct of globalisation. They can be the result of other supply chain disruptions, such as the current port and shipping delays being felt across the globe, due to COVID-19. Or they can be due to direct issues, such as cargo theft, shipping damage, or changing regulations. For example, Brexit sparked new regulations and tariffs, interrupting supply chains globally.

Last mile logistics also bring challenges. People nowadays have high expectations of speedy deliveries – both personally and professionally – and last mile logistics represents the most expensive and time-consuming part of shipping. The typical lack of transparency in this final stage of delivery makes it a prime place for disruptions and cancellations to occur.

The impact of supply disruption

Arguably the main objective of any supply chain management team, particularly the inventory management team, is to ensure that they have the right levels of stock available to meet upcoming demand. Unfortunately supply chain disruptions completely upset this equilibrium. And, when supply and demand are not balanced, this then affects operational costs and has a consequential knock-on effect on pricing.

Let’s take a deeper look at these challenges.

Supply shortages

Regardless of the reason for your supply chain disruption, the result will be the same – your inventory supply will be hit, making it extremely difficult to meet your fulfilment targets. If you’re a seller, this can cause stockouts, whilst manufacturers could face production stoppages – both can lead to unhappy customers.

Demand fluctuations

In contrast, fluctuating demand can also be problematic – especially when it is unplanned. If demand surges above and beyond your forecasts, this can lead to stock shortages, unless you have plans in place to mitigate the risk. And, when demand drops unexpectedly you could find stock piling-up in the warehouse and becoming excess or, in time, obsolete.

Price fluctuations

Supply and demand has always impacted price sensitivity: when demand is high and/or supply is limited, prices rise. When demand is low, and/or there’s excess supply, prices fall. These rules apply right along the supply chain, from raw materials, to transportation and the final price of goods. So when either one faces disruption, then price fluctuations are almost inevitable.

Right now many businesses are facing price hikes in shipping cargo around the world, due to container shortages and port delays, all stemming from the disruption caused by COVID-19.

How to manage supply chain disruption

With more and more organisations globalising their network of suppliers, it’s not a question of if, but rather when, disruption will occur. But there are still several tactics that you can use in your supply chain management strategy to safeguard your business. Here’s our top six…

1. Have an emergency back-up plan

Every business should have a contingency plan in place that kicks in when supply chain disruption is imminent. This should look at how you can continue to meet your top priorities, which may include hitting fulfilment KPIs, serving your most important customers, securing a supply of specific items or simply ensuring a steady cashflow.

2. Evaluate the current supply chain situation

Even with a contingency plan in place, when supply chain disruption occurs, it’s wise to stop, review the current situation and ensure your plan addresses all of the challenges you need to overcome.

These three broad questions will help you plug any gaps:

- How has the disruption specifically impacted your supply chain?

- What will it take for your supply chain to recover?

- How can you keep operations running smoothly in the interim?

Start by analysing upcoming demand and then review whether your suppliers’ current capabilities and your available inventory is sufficient to fulfil it. And, if not, look at what can be done to improve the situation.

Having total transparency along your supply chain is critical to carry out this task effectively.

3. Communication is key

Open and clear lines of communication are important with both suppliers and customers to make sure everyone understands the extent of the disruption, the next steps and how operations are being handled in the meantime.

It’s vital to be transparent with customers. Make sure they know what to expect from you (delayed or partial shipments, limited availability, price changes, etc.) and be clear about any challenges you face to help manage their expectations and build trust.

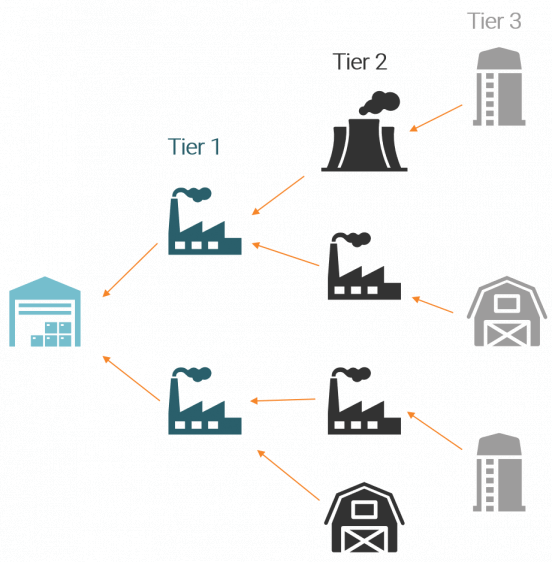

4. Minimise the number of supplier tiers

The longer your supply chain and the more tiers is has, the greater your risk of issues occurring. Following global supply chain disruption in 2020 and 21 due to COVID-19 and Brexit, some businesses are looking to reduce the number of tiers in their supply chain. Others are looking to use suppliers that are geographically located closer together, to help alleviate logistical issues and keep lead times lean.

This is not an easy or quick fix, however, as it takes time to research alternative partners, negotiate terms and set-up new ways of working.

5. Diversify suppliers

An alternative solution is to ‘edge your bets’ and source inventory from more than one supplier, using businesses strategically located across the world, so when issues arise in one country, there’s an alternative to hand. Supplier diversification also allows companies to negotiate better deals and access an increased selection of products.

6. Invest in tech

Investment in technology serves two purposes. Firstly, technology will help keep your supply chain secure of cyber attacks which are a costly disruption. There have been many high-profile data breaches in recent years, such as the Target data breach that affected 41 million consumers and resulted in the company paying an $18.5M settlement.

Secondly, technology will help give you the visibility and control to help you manage the moving parts of your supply chain. When supply chain challenges arise, software such as enterprise resource planning (ERP) and warehouse management systems (WMS) are invaluable tools to empower teams with the data they need to make the right decisions.

How can an inventory optimisation tool help?

When supply and demand are erratic, effective inventory management becomes extremely difficult. Inventory optimisation software can help alleviate supply chain risk and have a significant impact in a number of ways. For example, an inventory optimisation tool can:

- Monitor demand trends and automatically adapt reordering needs to sudden changes in demand.

- Track forecasting accuracy and create alerts when actual demand is deviating from the forecast, to help prevent over and under ordering.

- Compare stock forecasts to current stock levels and supplier lead times and create alerts of potential stockouts.

- Identify critical stock items e.g those needed to keep production flowing or sales flowing, so ordering can be prioritised.

- Create alerts when actual supplier lead times deviate from the norm and automatically adjust future reordering requirements to cover demand during the extended lead time.

- Recommend the best suppliers to fulfil an order, based on current lead times, unit prices and any ordering constraints e.g minimum order quantities.

- Create order calendars based on internal ordering and receiving capabilities. Then automatically recalculate reorder quantities and safety stock levels to prevent these issues impacting stock availability.

- Create supplier calendars that cover periods of planned supplier shutdowns, so ordering parameters are dynamically adjusted to ensure stock levels are adequate whilst supply is paused.

- Identify excess and obsolete stock that you could try to sell-off to recoup capital, while freeing-up warehouse space for more profitable items.

Building a more resilient supply chain

Supply chain disruptions are inevitable, but by responding quickly and decidedly you can manage their impact on your business. The coronavirus pandemic has taught many businesses the value of having plans in place to deal with the unexpected. Those with the infrastructure, processes and technology to deal with disrupted supply networks have often been able to ride the storm much better, than those without.

In the future, supply chain management teams will need to remain agile and ensure they have the tools they need to keep adapting to the challenges ahead.

If you’d like to know more about how EazyStock can help deal with supply chain disruption challenges, contact us for a demo.