How to reduce Brexit’s impact on your supply chain

Brexit supply chain risks

Right now, UK businesses are dealing with unprecedented times. The economic, social and political landscape in the UK is more uncertain than ever as we move into 2021. Not only have businesses got to deal with the impact of Covid-19, but they are also being urged by the Government to prepare for new trading rules with the European Union (EU).

Whilst leaders of the UK and the EU thrash out the details of what a post-Brexit era will look like, organisations need to start making plans to mitigate supply chain disruption as the transition period comes to an end. Nobody wants a repeat of the panic stockpiling and rush ordering that took place in previous years. No matter what the final rules and regulations end-up being, it’s critical that you consider Brexit as part of your supply chain planning for 2021, so you’re prepared for what lies ahead.

With this in mind, this post is going to look at six ways your business can reduce the impact of Brexit on your supply chain, going into January 2021 and beyond.

How can I manage my supply chain better to reduce the impact of Brexit?

1. Learn lessons from previous Brexit supply chain disruption

Supply chain management teams have had a tough time of late. Both Brexit and Covid-19 have led to erratic surges and/or declines in demand, with customers panic buying or sales completely drying up, depending on your industry. At the same time, inventory supply has been interrupted due to halts in production and transportation disruption. These dramatic fluctuations in demand and supply could easily continue well into 2021, so now is the time to review how you’ve dealt with the in the past and put processes in place to be better prepared next time round.

For example, identify inventory items which could be most affected by Brexit, predict what issues there could be and put plans in place to mitigate them. This could be as simple as increasing order quantities now for the start of 2021, or negotiating deals with new suppliers to change your supply route completely whilst uncertainty in the market remains.

2. Forecast for Brexit supply chain uncertainty and volatile demand

No-one knows how the UK economy will perform in 2021 and it’s going to be difficult to forecast demand in markets that are continually reacting to unprecedented political and economic uncertainty. For example, 2021 could see the UK enter a recession, or the Government invest heavily in certain sectors to boost the economy. Both scenarios will affect demand for your products in some way, and if you’re not tracking their sales, you could miss growth opportunities or risk investing in the wrong inventory.

Carrying out quarterly or even monthly forecasts may not be enough to ensure accuracy. In addition, if demand data from previous months has been skewed by the impact of Covid-19, it won’t be any use for forecasting future consumption.

Ideally you need to be reviewing and updating forecasts on a daily basis, so your supply chain can react faster to changes in demand to prevent stockouts and optimise sales.

Obviously, if you carry 100’s of SKUs this simply isn’t possible, so it maybe time to invest in software that automatically calculates your forecasts for you. You’ll then have refreshed data with which to make informed decisions. Demand forecasting software, such as EazyStock, tracks and adjusts forecasts on a daily basis, identifying changes in demand, creating alerts and suggesting order adjustments to cover the impact.

3. If stockpiling is a must, do so intelligently

Right now, many businesses will be fighting the urge to stockpile inventory that could be affected by new EU trading laws. Whilst stockpiling may help prevent stock shortages, the major downside is that it ties-up unusually high amounts of working capital. This will no doubt affect cashflow and liquidity. Brexit stockpiling can also result in excess and obsolete stock if the levels are not eventually brought back in line with demand.

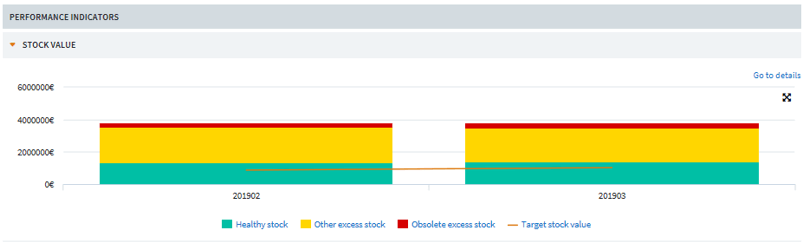

It’s therefore critical to continually analyse the stock you carry in terms of whether it is ‘healthy’ e.g it can meet forecasted demand, it’s in excess of forecasted demand or it’s ‘obsolete’ and has had no demand for a certain period of time.

This overview of the ‘health’ of your inventory will help inform your Brexit supply chain and purchasing decisions.

Obviously during times of stockpiling you’ll have abnormal levels of excess, even obsolete stock, but once you’re ready to start reducing them, you’ll want to see items move back to the ‘healthy’ zone.

4. Speed-up stock reduction after stockpiling

Unfortunately, the process of reducing stock levels can be very resource-intensive without automation. For starters you’ll have to manually calculate forecasts, safety stock levels and reorder quantities in spreadsheets, then, as stock begins to decrease, you’ll need to continually update these calculations and enter the data back into your ERP, so re-ordering can reach a new ‘norm’.

Again there is software available to automate these processes and dynamically adjust stock levels and reordering parameters, without the need for manual calculations. An inventory optimisation tool, such as EazyStock, will optimise inventory levels and recommend the right stock to carry.

A starting point for this is the system’s ability to analyse current stock levels of each SKU you hold, identifying excess and obsolete inventory. Then, by using a daily feed of your current stock levels and creating future demand forecasts, the system will automatically update your ordering calculations to recommend optimised order requirements. This data is fed back into your ERP, so it can dynamically adjust stock levels and only order what you need to fulfil demand.

5. Better management of Brexit supply chain delays

Many businesses are concerned about supply uncertainty when trading rules change with the EU. And whilst you cannot wave a magic wand to prevent supply chain disruption happening, you can put a number of processes in place to help you manage any issues. For example:

- Actively track supplier lead times and increase reordering quantities, or bring forward future orders to compensate for delays.

- Increase safety stock levels if supplier lead times increase, so you have greater quantities of buffer stock to help prevent stockouts.

- Identify products at risk of run out and prioritise their management e.g you could increase prices to slow down sales, move stock from other locations, use substitutions or find a different interim supplier.

An inventory optimisation tool, such as EazyStock, has functionality to support with all the above processes, allowing you to track ‘at risk’ items and adjust reordering more efficiently, so you can react to supply issues quicker.

6. Invest in technology to make your supply chain more agile

With so much to think about right now, introducing new technology to your organisation might seem like a crazy idea. However, digitalising your supply chain could help support your business through times of uncertainty in three ways:

- It helps cut costs and improve productivity.

- It can provide the transparency and data analytics businesses need to identify areas of improvement and opportunity.

- It helps make businesses more agile and better able to adapt to the uncertainty and rapid change that comes with a slowdown and subsequent period of growth.

When marketplaces are moving so quickly, you need access to the best tools to help you be as efficient at your job as possible. You also need access to data so you can make decisions based on the facts and react quicker to supply chain disruption or erratic changes to demand.

Better post-Brexit supply chain planning is critical

As the Brexit transition period comes to an end, many purchasing teams will need a tighter grip on their supply chain strategy and inventory management processes. To navigate through these turbulent times, having accurate and insightful data will be critical to help make informed decisions. In addition, businesses that can respond quickly to changes in supply and demand will also be in the best position to prevent stock-outs and keep customers happy.

If you’d like to know more about how EazyStock can enhance the inventory management capabilities of your ERP system, call us on 0121 312 2992 or request a demo.

First published January 2020, updated November 2020