What’s driving supply chain digitalisation and what are the benefits?

What is supply chain digitalisation?

Supply chain digitalisation is when a business embraces digital technology to improve its processes and how it works both internally and with customers and suppliers. It takes human-driven events and uses digital technology to make them software-driven.

Some businesses take this one step further and use digitalisation to enable supply chain digital transformation. This is when business processes are completely changed due to the introduction of digital technologies.

Many businesses are on a supply chain digital transformation journey. In this post we look at what is driving this and what the benefits are in both the short and long term.

What is driving supply chain digitalisation?

For many UK businesses, the coronavirus pandemic has acted as a catalyst and accelerator to supply chain digitalisation. Since 2020, many manufacturers, suppliers and wholesalers have been forced to adopt new ways of working with social distancing, closing offices and reducing operational capacity. At the same time, companies have also had to deal with erratic customer behaviour and badly disrupted supply chains.

With supply chain disruption still a big challenge, many businesses are using technology to help make their operations more agile and resilient, so they’re in the best place to respond to the ever-changing economic and social landscape. The need to build resilient supply chains is a big driver of digitalisation.

In the MHI’s (Materials Handling Institute) latest Annual Industry Report “Innovation Driven Resilience”, businesses from across the globe were surveyed at the end of 2020 and 83% believed that digital will become the predominant model within the next five years.

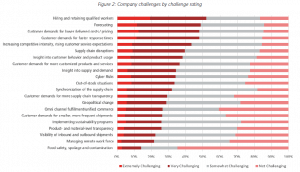

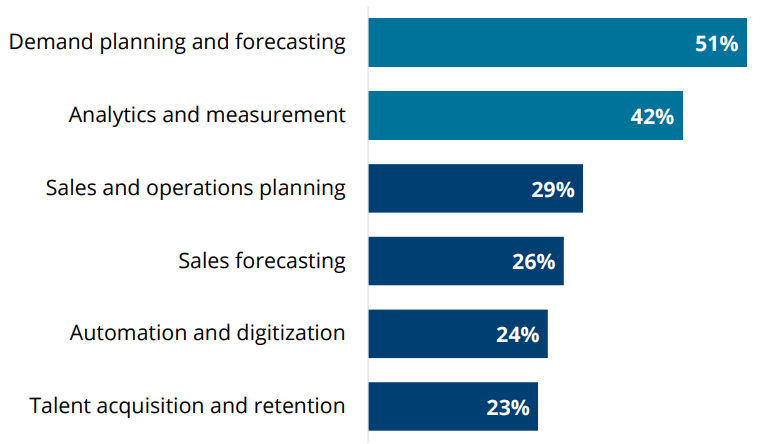

The key supply chain challenges businesses are trying to overcome with the use of technology are shown in this chart:

Many of these challenges, such as supply chain disruption, demand forecasting difficulties and out-of-stock situations have arguably been aggravated by the coronavirus pandemic.

The consequential increase in online sales has also heightened customer demand for faster delivery times and rising customer service expectations whilst increasing competition in many industries.

When we focus in on the digitalisation of supply chain planning, a 2022 report by the APQC (American Productivity & Quality Center) shows this is being driven predominantly by a need to improve demand planning and forecasting, and analytics and measurement.

Demand-driven supply chain management is nothing new. However, traditional methods of demand forecasting that use spreadsheets to analyse historical data are simply not good enough to handle today’s market fluctuations. Technology is needed for much smarter data analytics to deliver more accurate forecasting and replenishment.

As more and more data gets produced, supply chain management teams are drowning in reports. They need the right tools and software to turn the numbers into meaningful insights and measurement criteria. Data is no good unless you can leverage its power.

With these challenges in mind, this chart shows which supply chain technologies are predicted to be widely adopted in the next one to five years:

Many businesses are on a digital journey and, as they begin to reap the benefits of introducing new technologies, there will be no turning back.

From creating connected teams using virtual streaming and collaboration tools, to increasing productivity with machine learning, to establishing new routes to market via ecommerce. Businesses that want to survive are transforming – and they’re using technology to do so.

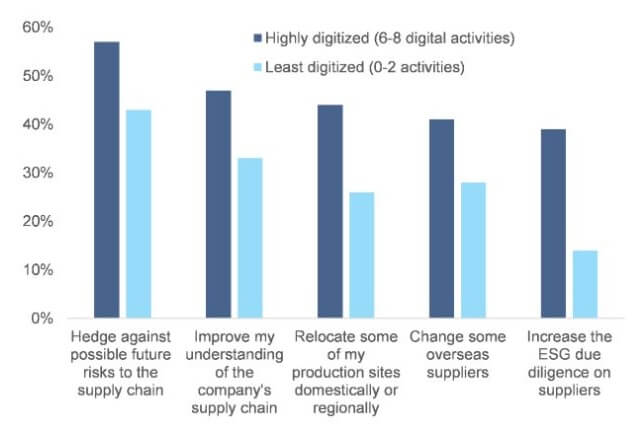

And there’s already evidence that digitalisation is working. A survey by Euler Hermes in late 2020 showed that highly digitalised companies (reporting six to eight different digital activities) took significantly more actions to mitigate supply chain disruptions than less digitalised ones (reporting zero to two digital activities).

The survey argues that this is because they had the infrastructure, operational efficiency and data transparency to proactively respond to the global crisis.

The benefits of supply chain digital transformation

The internet is full of articles that talk about the advantages of supply chain digital transformation. Here’s a summary of the main benefits:

Improved flexibility and responsiveness to change

By embracing technologies such as predictive analytics, or automating stock management processes, businesses are more likely to identify upcoming challenges earlier and have the capability to dynamically react to them.

As a consequence, they’re better positioned to deal with rapid change that comes with supply and demand fluctuations.

Ability to handle big data and at a granular level

Technology provides the data insights that businesses need to make informed decisions and identify areas of improvement and opportunity.

It also allows teams to dig into data at a granular level – whether this is tracking individual SKUs along a supply chain or forecasting stock levels item by item.

Better accuracy

Moving from human-led to software-led processes removes the element of human-error. With advancements such as real-time tracking, comes the benefit of total transparency of business operations at each stage of the supply chain.

Greater efficiency

If businesses can integrate and speed-up processes, this leads to greater operational productivity. Examples of this include introducing picking software or conveyor automation to make warehouse processes more efficient.

Improved competitiveness

There’s a growing volume of empirical evidence that suggests digitalisation can help businesses during times of economic uncertainty, e.g recessions and economic slowdowns.

A study published in Harvard Business Review (HBR) in 2010 looked at 4700 public companies in the USA before, during and after the recessions of 1980, 1990 and 2000 and closely reviewed the performance of each one. It found that 9% of companies flourished after the slowdowns, with them all having a similar strategic approach:

- They cut costs through improvements in operational efficiency

- They invested in assets such as technology, plant and machinery

- They invested in R&D and marketing

This allowed them to outperform their competitors by at least 10% in terms of sales and profits growth.

Digitalising your supply chain by introducing inventory optimisation software

Introducing an inventory optimisation tool, such as EazyStock, is one way to digitlise inventory management processes. Here’s some examples of how it could benefit your business:

- Accurate demand forecasting

EazyStock’s demand forecasting features use statistical algorithms to generate baseline forecasts that are more accurate and reactive than using a 30-day rolling average calculation in Excel or an ERP.It also considers demand trends and volatility in calculations and let’s teams add qualitative forecasting data, such as customer feedback and market intelligence. These features are critical with marketplaces changing daily, so forecasts can be as accurate as possible. - Supply and demand volatility alerts

EazyStock has a suite of alert reports to help spot and manage supply and demand challenges. These include:

– A risk-of-run out report that details stock items that are at risk of going out of stock, so a plan of action can be formed.

– Demand-to-date alerts that constantly check actual demand against consumption throughout the forecast period and flag when it’s deviating significantly from projections.

– A demand fliers report that highlights forecasting anomalies, so you can decide whether the dip/increase is realistic and whether to allow the system to include it in future forecasts and update replenishment calculations accordingly. - Data transparency

Users of EazyStock have a transparent view of their inventory, including which items are in greatest demand, are picked the most frequently, have the most volatile sales patterns and cost the most to sell. Armed with this data you can then focus on investing in inventory that will generate the greatest revenue, and securing the supply of the most important stock items. - Supplier lead time tracking

If lead times increase, EazyStock can adjust reordering quantities accordingly, to help prevent stockouts. Then, as they improve over time, quantities will re-adjust to help prevent a build-up of excess stock. - Automated replenishment

EazyStock automates all stock forecasting and replenishment calculations, such as reorder quantities and safety stock levels. With this data dynamically generated, teams can simply check order recommendations and send them for processing in their stock ordering system, giving them much more time to deal with other pressing matters.

If you’d like to know more about how EazyStock can support your supply chain management operations, please get in touch with a our team today.