The problem with the Economic Order Quantity (EOQ) model

The economic order quantity (EOQ) model is a fairly popular means of calculating inventory reorder quantities and working out how many orders to place per annum. However, EOQ is often criticised for being overly simplistic and relying on consistent data inputs that don’t really reflect reality. In this post, we take a closer look at the EOQ model and its limitations.

What is Economic Order Quantity (EOQ)?

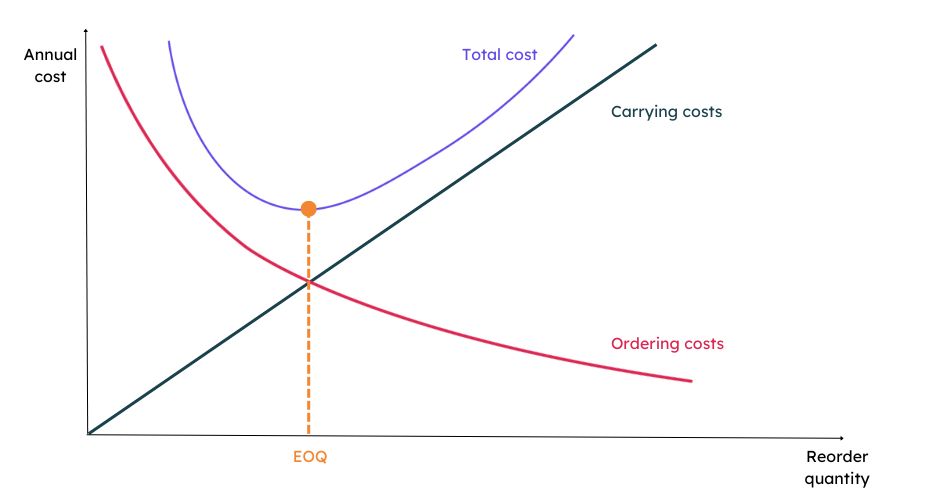

The Economic Order Quantity (EOQ) is the ideal quantity at which inventory carrying costs and ordering costs are at their lowest. Inventory planners use the EOQ model to determine the most ‘cost-effective’ amount of stock to reorder.

Economies of scale state that the more goods you procure in one order, the lower the ordering cost per unit. However, the more items you hold at one time in your warehouse, the higher your carrying costs will be. The economic order quantity will identify when both of these costs are at their lowest.

Our blog post on how to calculate economic order quantity gives you a working example of how to use the formula.

Limitations of the Economic Order Quantity (EOQ) model

Many inventory planners think that finding the right EOQ for each item they stock will help them achieve lower inventory costs. On paper, this may be the case, but in reality, there are many limitations to this over-simplistic framework. Here are some key problems:

How do you deal with demand fluctuations?

Using the EOQ model would be relatively simple for a business that has consistent demand for each inventory item throughout the year – but this is often not the case. Firstly, as items move through their product lifecycle, their demand will change. For example, products in the growth stage will see demand increase over time, whilst those at the end of maturity and facing decline will tend to see demand get lumpier and more inconsistent before it drops off.

Secondly, many products have seasonal demand, where sales rise and fall at certain times of the year. Calculating your EOQ at the start of the year and sticking to it could lead to periods of stockouts when demand is high or excess inventory building up in the warehouse when it falls off because reordering hasn’t considered seasonal peaks and troughs.

Finally, demand will be influenced by an item’s selling price and promotional activity.

To stay on top of demand fluctuations, you need to recalculate your EOQ on a regular basis. If you have a large number of SKUs to manage, this could become a time-consuming and impractical task.

Can my warehouse and staff manage more frequent purchase cycles?

In our working EOQ example, the EOQ calculation determined that the inventory planning team needed to place orders for their best-selling spinning top approximately 14 times per year – that’s more than once a month.

While EOQ gives you the best reorder quantities to minimise costs, you also need to consider if your planning team and your warehouse staff can practically manage the recommended frequency of orders and deliveries. Plus, EOQ will give you a different reorder frequency for every item you carry – how do you keep track of the ordering schedule for every inventory item when they could all be at different times?

The EOQ model fails to consider current stock levels in your warehouse network

If your demand drops between placing one order and the next, you may find you don’t need to order the same quantity as your original EOQ formula recommended. Simply following the formula without revision could lead to excess inventory building up in your warehouse.

In addition, your demand for certain items may vary from one warehouse location to another. Therefore, simply reordering items based solely on EOQ can be a waste of resources if the items you need are simply in a different stocking location. In this case, rather than reordering, redistributing those items to where they are needed within your network is a more valuable use of time.

All items in your warehouse are not of equal value

In many businesses, some items will be more profitable than others, and some will cost more to sell than others. The EOQ model, however, treats all inventory items the same, regardless of their value to the business. It assumes you need to stock every item with equal importance and assumes that every item has fixed costs that never fluctuate.

This means you could find that you’re wasting valuable space on items that you don’t need to have in stock at the expense of running out of your best-sellers.

Prioritising your higher-demand and more valuable SKUs will ensure that you maintain high customer service levels. You can determine which SKUs are your most valuable with ABC analysis.

Will EOQ orders meet the minimum order quantity (MOQ) requirements of your suppliers?

Ordering a little and often gives inventory managers more flexibility to align purchasing patterns with actual customer demand. However, many suppliers require a minimum order quantity (MOQ) before they send out a shipment, so you may still end up ordering more than your EOQ formula recommends.

EOQ assumes immediate availability of stock

The EOQ model does not take into account supplier lead times, it simply tells you how much to order based on demand. To cover lead times, you may want to add a level of safety stock, but if deliveries are late, you could find you’re left unable to fulfil important orders.

Overcoming problems with the Economic Order Quantity model

While this isn’t an exhaustive list of EOQ limitations, it clearly demonstrates that using the economic order quantity as a reordering method will lead to inventory management issues.

There are many other ways to calculate reorder points and reorder quantities – EOQ is just one option. However, effective inventory replenishment requires the constant monitoring of demand, current stock quantities, pick frequencies, safety stock levels, supplier lead times… and the list goes on. With so many variables to consider, it’s wise to enlist the help of software. This will speed up otherwise manual calculations and help ensure data accuracy.

EazyStock is an inventory optimisation tool that plugs into ERP systems and automatically calculates reorder quantities. It carries out statistical demand forecasting, sets dynamic inventory levels and recommends when to reorder and by how much. With EazyStock, inventory planners don’t have to spend hours number crunching in excel spreadsheets, instead they have access to a wealth of accurate inventory data in EazyStock that they can use to manage their inventory and ensure reordering reflects supply and demand variables.

If you’d like to know more about how EazyStock can improve the accuracy and efficiency of your inventory planning, contact us for a demo.