What is supply chain digitalization and why is it important?

For many businesses the spread of Coronavirus has acted as a catalyst and accelerator to digitalization. Manufacturers, suppliers and wholesalers across the US have been forced to adopt new ways of working with social distancing closing offices and reducing operational capacity. At the same time, companies are dealing with erratic customer behavior and badly disrupted supply chains. With little certainty about what the future holds, supply chain management (SCM) teams are looking for ways to make their operations more agile and resilient, so they’re in the best place to respond to the changing economic and social landscape.

Why COVID-19 is driving supply chain digitalization

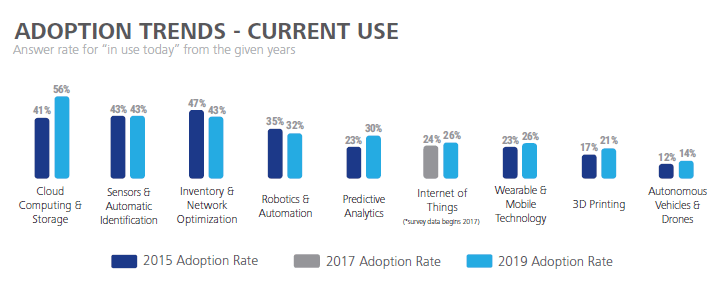

In 2019 MHI and Deloitte published their report “Elevating Supply Chain Digital Consciousness”. The report investigated the adoption of key supply chain technologies by businesses of all sizes across the globe, between 2015-19:

The lack of investment in digitalization is disappointing, but not surprising. As many managers are aware, there are often many obstacles to digitalization, from internal bureaucracy and justifying CapEx investment, to simple reluctance to change current ways of working.

Right now, however, it’s clear to see that these barriers are being pushed aside, as organizations battle to overcome the challenges that the Coronavirus pandemic brings. Businesses that were ‘putting off’ change are now embracing it full-on. SCM teams, in particular, are using their rapid adoption of digital processes as a way to deal with the evolving trading environment they face, both now and into the future.

Many businesses are on a digital journey and, as they begin to reap the benefits of introducing new technologies, there will be no turning back. From creating connected teams using virtual streaming and collaboration tools, to increasing productivity with automation despite smaller workforces, to establishing new routes to market via eCommerce. Businesses that want to survive are transforming – and they’re using technology to do so.

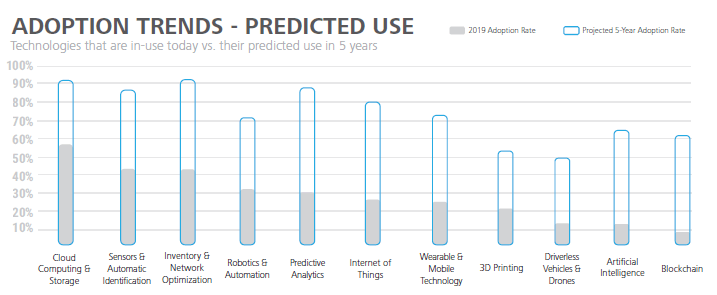

Findings from the same MHI report suggest that even based on 2019 predictions, businesses are moving in the right direction.

With COVID-19 driving digital transformation going forward, the adoption of these technologies could come sooner and on a much larger scale.

Unfortunately, no one knows what the future holds for US commerce. Cases of COVID-19 could rise and fall for the foreseeable future, leading to stops and starts in our economy, and peaks and troughs in demand. Global supply chains could also remain disrupted, as nations battle to keep the virus under control.

And, once US SCM teams have overcome the state of flux caused by this Coronavirus, they will have to prepare for a changed supply chain future. Businesses that are investing in digitalization now will be much better prepared to face the challenges ahead.

The benefits of supply chain digitalization

There’s a growing volume of empirical evidence that suggests digitalization can help businesses during times of economic uncertainty, e.g. recessions and economic slowdowns. A study published in Harvard Business Review (HBR) in 2010 looked at 4,700 public companies in the US before, during and after the recessions of 1980, 1990 and 2000 and closely reviewed the performance of each one. It found that 9% of companies flourished after the slowdowns, with them all having a similar strategic approach:

- They cut costs through improvements in operational efficiency

- They invested in assets such as technology, plant and machinery

- They invested in R&D and marketing

This allowed them to outperform their competitors by at least 10% in terms of sales and profits growth.

In a more recent HBR article, Katy George, Senior Partner at McKinsey, provided four key reasons why investing in digitalization is crucial to businesses looking to survive/grow during economically challenging times:

- It helps reduce operational costs and improve productivity

- It creates transparency across business operations and the supply chain

- It provides the data analytics that businesses need to make informed decisions and identify areas of improvement and opportunity

- It makes supply chains more agile and able to respond quicker to the rapid change that comes with a slowdown and subsequent period of growth

How supply chain digitalization can support a COVID-19 recovery plan

McKinsey has recently published a six-point plan to help supply chain management teams react to the impact of COVID-19. This includes:

- Creating transparent supply chains: Identifying which inventory items are critical in the supply chain; items whose supply is most at risk of interruption and alternative sources of supply.

- Locating available inventory in the supply chain: Identifying where there is spare inventory capacity to either keep production running (manufacturers) or fulfill important orders (suppliers).

- Assessing customer demand: Looking for realistic demand signals hidden behind erratic customer behavior to ensure stock levels reflect new behaviors.

- Adjusting production and distribution capacity: Understanding new operational capacity limits, while still ensuringemployee and customer safety.

- Identifying and securing logistics capacity: Being flexible on transportation modes and switching when required.

- Managing cash and net working capital: By running stress tests to understand where supply chain issues will start to cause a financial impact.

This plan can help supply chain managers identify the risks associated with their organization’s supply chain and how to mitigate them to keep disruption to a minimum. McKinsey points out that digitalization of the supply chain will be key to helping teams deal with these challenges.

This plan can help supply chain managers identify the risks associated with their organization’s supply chain and how to mitigate them to keep disruption to a minimum. McKinsey points out that digitalization of the supply chain will be key to helping teams deal with these challenges.

Digitalizing your supply chain by introducing inventory optimization software

An inventory optimization tool, such as EazyStock, is one way that technology can support supply chain managers with their current inventory management issues. Here’s some examples of how:

- Inventory optimization software automates demand forecasting. This allows inventory teams to use statistical algorithms to generate baseline forecasts that will be more accurate and reactive than using a 30-day rolling average calculation in Excel or an ERP. The tool also lets teams add qualitative forecasting data, such as customer feedback and market intelligence to add ‘human insights’. It also tracks demand trends, which is critical with marketplaces changing daily, so forecasts can be as accurate as possible.

- EazyStock offers functionality to help businesses manage supply and demand volatility. This includes a risk-of-run-out report that details stock items that are at risk of going out of stock so a plan of action can be formed. Demand-to-date alerts constantly check actual demand against consumption throughout the forecast period and flag when it’s deviating significantly from projections, so you can track the item more closely. At the end of a forecast period, demand fliers (anomalies) are highlighted, so you can decide whether the dip/increase is realistic and whether to allow the system to include it in future forecasts and update replenishment calculations accordingly.

- EazyStock users have a transparent view of their inventory in terms of which items are in greatest demand, are picked the most frequently, have the most volatile sales patterns and cost the most to sell. Armed with this data, they can then focus on investing in inventory that will generate the greatest revenue and securing the supply of their most important stock items.

- With functionality to track supplier lead times, EazyStock adjusts reordering quantities accordingly, so if lead times increase, reorder quantities go up. Then, as they improve over time, quantities will re-adjust to help prevent a build up of stock.

- By automating forecasting and replenishment tasks, inventory management teams will reduce their time spent churning data and manually calculating replenishment parameters, such as reorder quantities and safety stock levels. With this data automatically generated by EazyStock, teams can simply check order recommendations and send for processing in their ERP, giving them much more time to deal with other pressing matters.

If you’d like to know more about how EazyStock can support your supply chain management operations in 2020 and beyond, please get in touch with a our team today.

If you’d like to know more about how EazyStock can support your supply chain management operations in 2020 and beyond, please get in touch with a our team today.