Bill of materials’ (BOM) importance in inventory management

What is a bill of materials (BOM)?

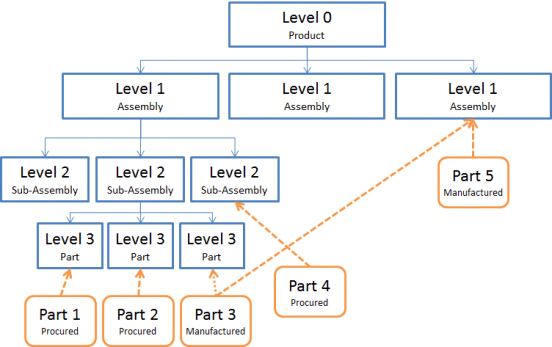

In its simplest form, a bill of materials (BOM) is a list of components, parts or materials required to manufacture, assemble or repair a product. A BOM is often hierarchical, with the finished product at the top and sub-items below.

In inventory management a BOM is critical to ensure the correct quantities of each item are procured and available at the right time, to prevent delays along the supply chain.

Types of bill of materials

There are a number of different types of BOM, including:

Manufacturing bill of materials (MBOM): a manufacturing BOM is a structured, comprehensive list of assemblies, sub-assemblies and materials required to manufacture a product. An MBOM also includes information on the individual items, how they relate to each other and instructions on how to assemble them during the production process.

Engineering bill of materials (EBOM): an engineering BOM shows the make-up of a product from a design perspective. It often details engineering information such as raw materials. specifications, tolerances, and standards.

Assembly bill of materials: an assembly BOM is often used to create a list of items required in the assembly of the finished good. This is often less complicated than an MBOM.

Service bill of materials (SBOM): a list of items needed to service an asset e.g machinery, equipment or a product. An SBOM only contains information that is relevant to the person ordering the parts and servicing the asset e.g. a list of serviceable parts, replacements and part supersessions. Sometimes a SBOM will also include information on how to carry out the service job.

Sales bill of materials: represents items that are assembled at the sales stage and sold together as one sales item e.g. a sales kit. This could be a cooking recipe kit, garden furniture or a jewellery set.

How do you make a bill of materials?

Here are some of the key elements required when creating a BOM:

1. The BOM level

Each component has a number outlining the point it becomes necessary in the overall assembly plan. This shows its place in the hierarchy of assembly. Sub-assemblies will be numbered closer to the completion stage than their component parts. This is illustrated in the diagram below.

2. Manufacturers’ part number (MPN), item name and description

Each part and sub-assembly needs a unique number, name and description for easy identification. It is important that there are no duplicates to avoid confusion.

3. Phase

It is important to know where each assembly part is in its own product life cycle. The purpose of this is to ensure that each sub-assembly phase has been completed before the next phase. A part may be labelled as ‘in production’ if it has yet to be completed or ‘in design’ if it has yet to be approved. Individual components may also be described as ‘ready for use’. When designing new products, this can help to plan timescales and pricing.

4. Quantity and unit of measurement

This is the quantity of each component needed to produce the final product. This allows the correct amounts of each item to be ordered and stored. If a predicted quantity of the final product is provided, then forecasts for every component within the BOM can be calculated.

It’s important to use consistent units of measurement and sizes across all similar parts, to avoid any confusion with stock planning and purchasing.

5. Procurement type

It is worthwhile to document how each component is procured e.g the manufacturer, or supplier used, the lead time, whether it is made-to-measure or off-the-shelf etc.

The importance of having a bill of materials

The benefits of having a BOM include:

Transparency

A bill of materials gives everyone a framework to follow, so teams involved in the procurement, assembly or repair of the product know what is required of them. A BOM helps simplify sometimes complex processes and gives transparency.

Availability

Perhaps most importantly for inventory management and purchasing teams, a BOM provides a clear list of materials and quantities. By calculating a forecast for the finished product, a BOM can help explode out forecasts for each individual component so ordering can be as accurate as possible.

Efficiency

Using a BOM can help improve efficiency right along the supply chain. If items arrive on time there’s less risk of delays to production, servicing or sales order completions.

Less wastage

With an accurate bill of materials, stock levels can be optimised. This involves ordering the right amount of stock to meet production or servicing schedules, or to fulfil forecasted sales. This reduces capital tied up in inventory and associated carrying costs.

Next generation BOM: The future of bills of materials planning

Technology is playing an increasingly important role in creating and managing bills of materials. Many materials resource planning (MRPs) and enterprise resource planning (ERP) systems are equipped to carry BOM structures and automate workflows to ensure components are in the right place of the supply chain to fulfil demand.

Inventory optimisation software, such as EazyStock, is also being used by inventory planners to automate BOM forecasting and dynamically update the reordering parameters of BOM-dependent components. These accurate and timely BOM forecasts can then feed into the ERP or MRP systems for purchase orders to be created.

Read our post “How to improve BOM forecasting and planning” for more information. Or, if you’re interested in a demo showing how BOM functionality works in EazyStock, or what other great inventory management features the system can offer, please get in touch.