Importance of safety stock in inventory management

What is safety stock?

You might be a manufacturer working on an order when you realise you’re out of a necessary component due to a sudden increase in demand. You can’t finish the order until you’ve placed the order and received that part, which delays customer delivery.

Maybe you’re a distributor who received a regular order from a customer, only to find that your supplier is experiencing unexpected, longer-than-usual lead times. This means you can’t fulfil your customer orders on time.

In both cases, customer service levels are negatively impacted by a challenge that could have been prevented by carrying safety stock.

Safety stock, sometimes called buffer stock, is the extra level of stock (raw materials or finished goods) carried to mitigate the risk of run-out due to supply or demand uncertainties. It is an important aspect of inventory management and should be considered at all stages of the supply chain.

In both examples, buffer stock could have been added to reorder point calculations to prevent service levels (stock availability) from being negatively impacted by supply and demand variables.

What is the purpose of safety stock?

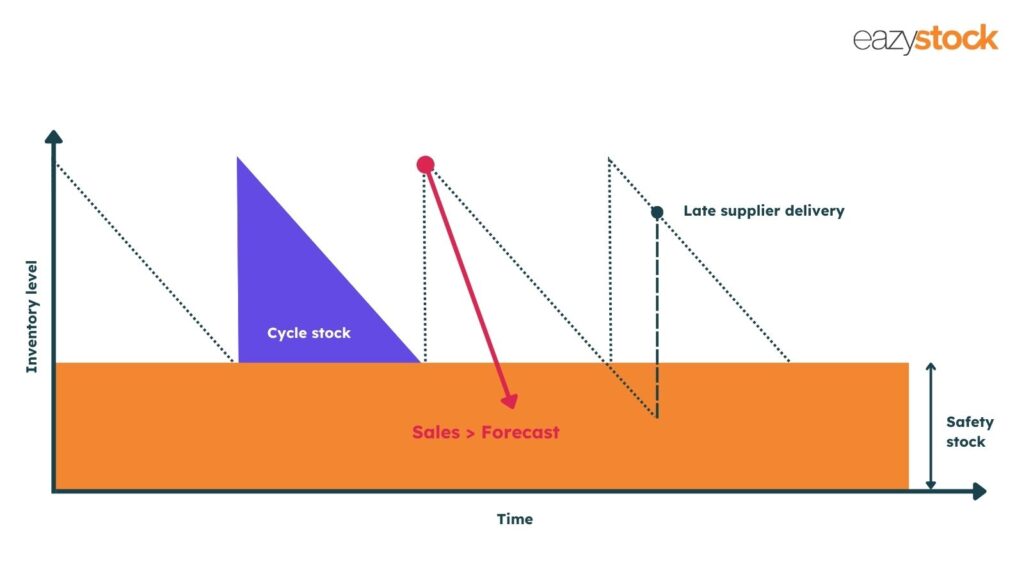

Safety stock ensures that, once you’ve used up your cycle stock (stock you expect to sell during a specific period), you still have some contingency to fulfil orders, even if there are unexpected changes in demand or in supply.

To maintain high customer service levels, it’s essential to calculate and use accurate safety stock requirements. Using a trial-and-error strategy or rules-based approach to cycle stock and safety stock results in stock imbalances.

Unfortunately, rules-based approaches tend to be a “one-size-fits-all” approach to inventory management, for example, holding a certain number of weeks of historical average demand, such as four weeks of cycle stock and two weeks of safety stock.

While the “one-size-fits-all” rule will deliver the right amount of inventory for some items, it will deliver too much or too little to meet service levels for others. These inventory imbalances simultaneously result in excessive inventory costs, impeded cash flow, and poor or inconsistent service levels. They are also only sensitive to demand changes, not supply disruption.

Why do you need safety stock in inventory management?

Setting safety stock levels is a necessity for any business building resilience into their inventory management processes and supply chain planning. Here are four key reasons why even small- and mid-sized businesses should carry safety stock:

- protect against unforeseen supply variations

- compensate for forecast inaccuracies

- prevent a fire-fighting mentality

- avoid stock-outs and keep customers happy

1. Safety stock protects against unforeseen supply chain disruption

Supply chains are longer and more globalised, with more forces causing disruption than ever before. If your supplier unexpectedly closes for a week or there is a disruption to delivery, safety stock allows you to continue to fulfil customer orders.

2. Safety stock compensates for forecast inaccuracies (when demand exceeds the forecast)

Not all items in your inventory will have consistent demand patterns. Some will have lumpy or erratic demand, e.g., periods when demand is low or non-existent and periods where it’s much higher. This makes it harder to forecast upcoming demand accurately. Safety stock can be used to cover periods when demand exceeds the forecast.

If you have consistent demand for a certain item, but one month you experience a surge in demand and sell more than your forecast, safety stock will cover this without sacrificing your customer service levels during replenishment.

3. Safety stock prevents disruptions in manufacturing or deliveries

Safety stock helps maintain high customer service levels and a smooth supply chain. It reduces stress and administrative time for your teams. Instead of trying to locate and reorder ‘emergency stock’, they can concentrate on fulfilling customer orders. Reducing costly backorders also benefits your bottom line.

4. Safety stock helps avoid stockouts to maintain high customer service and satisfaction levels

Safety stock’s ultimate goal is to keep your customers happy. While safety stock indisputably helps mitigate supply chain risks, its end goal is to maintain stock levels to ensure customer satisfaction and keep them coming back.

Safety stock is a ‘no-brainer’

Since each SKU in your inventory has a unique demand pattern, you need to adjust your safety stock levels accordingly. Safety stock requires a tailored approach that considers more factors than. rule-based approaches offer. For example, accurate safety stock levels include service levels, forecast accuracy, and lead time variability.

A sound, mathematical approach to safety stock calculations not only justifies the required inventory levels to business leaders, but also balances the conflicting goals of maximising customer service and minimising inventory costs.

With many supply chain challenges and uncertainties, safety stock is important for mitigating risks from supply disruption and dealing with the consequences of inaccurate demand forecasts. Stock availability is a crucial element to delivering great customer service, so the importance of buffer stock should not be underestimated.

Learn more

To understand best practices for calculating safety stock for your business, download out free eGuide, “How to calculate safety stock for inventory management”.

If you’d like to discuss how EazyStock can support your business with automated safety stock calculations, contact our expert team today on 0121 312 2992 or request a demo.

First published 24 April 2018, updated June 2021, and January 2026