Classifying inventory and optimising stock levels with Dynamics 365 Business Central

Stock classification is an important part of effective inventory management. By grouping stock items based on their value to your business, you can prioritise which items to stock/not stock and in what quantities. It can also help you focus your time, in terms of analysis, forecasting, and ordering, on the groups that are most important to the business.

Ultimately, stock classification is a useful tool for ensuring you’re carrying the correct levels of each inventory item and preventing over- or under-stocking.

In this post, we’ll examine the inventory classification functionality in Microsoft Dynamics 365 Business Central/NAV and explain how EazyStock can deliver additional capabilities.

EazyStock is an established inventory optimisation app that can be found in Microsoft Appsource. With our ready-made connector, it’s easier than ever to integrate EazyStock with Business Central to provide advanced inventory management capabilities. In other posts, we’ve looked at demand forecasting and replenishment. In this one, we’re going to focus on inventory classification and stock level optimisation. Here’s an overview of what these are:

ABC inventory classification and Business Central

Dynamics 365 Business Central uses a simple and very common form of inventory classification, called ABC inventory analysis, to inform its stock management and reordering calculations. To use an ABC analysis framework with Business Central, you first need to manually categorise your stock items into groups based on similar characteristics. This is typically done in a spreadsheet.

Microsoft defines ABC classification as grouping items based on their value and volume relative to total stock. So ‘A’ items, which have a high value and are stocked in low volumes, are treated differently to ‘C’ items, which conversely are carried in high volumes and have a low comparative value.

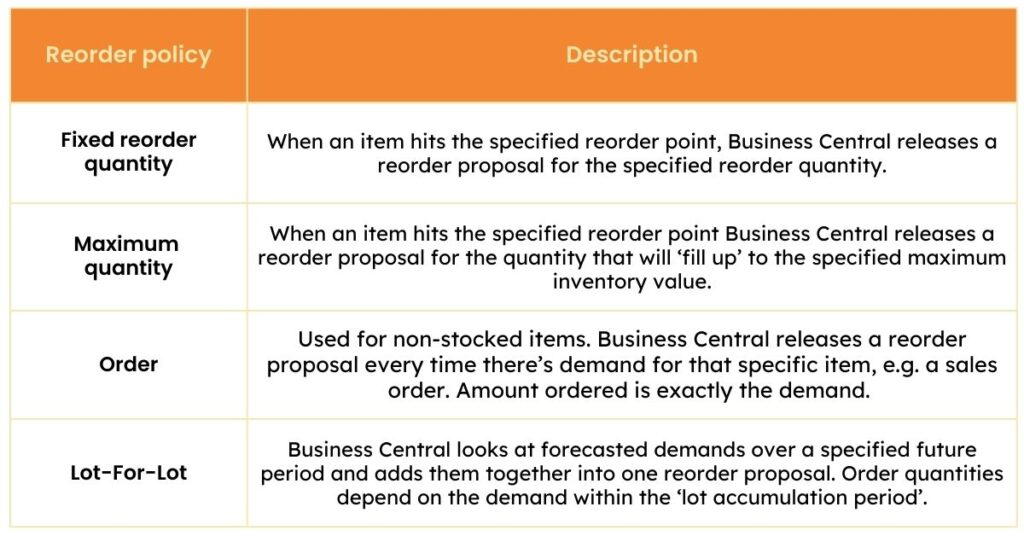

With your items categorised you then need to upload this information into your ERP and then assign a suitable reordering policy to each item. In Business Central, there are four reordering policies:

Each can be assigned to different ABC categories. For example, you may assign the ‘Order’ reorder policy to A items because they are more expensive and therefore not stocked, or assign the ‘Maximum Quantity’ reorder policy to C items that you’re happy to stock in larger volumes.

However, analysing and classifying every inventory item is a time-consuming task for any inventory manager. Unfortunately, as soon as the information is calculated, it will begin to fall out of date because items can move between categories due to changes in demand or cost. This can then lead to unsuitable levels of stock being ordered and consequential stockouts or excess stock situations occurring.

Dynamic inventory classification

In comparison, with EazyStock, inventory classification is much more advanced. Instead of categorising items into three groups, EazyStock includes a much wider range of classification variables.

To do this, EazyStock takes a daily feed of demand profiles, stock levels and items on order and in transit from Business Central and calculates stocking rules for every SKU, based on a number of key criteria:

- Demand types – as discussed above.

- The value of annual usage (VAU) of each SKU – this takes into account sales volume as well as the unit cost of the product.

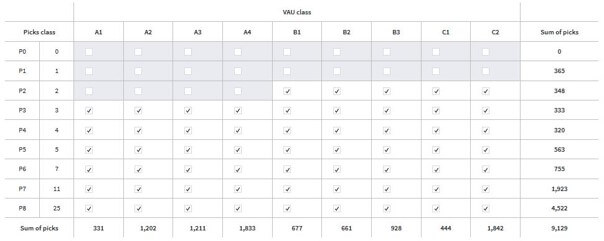

- How often each SKU gets picked – this distinguishes high-volume products with many requests (1000 requests for 1 unit) from high-volume products with low requests (2 requests for 500 units).

- The demand volatility of each SKU – segmenting items based on their demand volatility and, therefore, how easy their demand is to forecast.

Whilst ABC classification simply groups items based on their value, EazyStock uses multi-dimensional variables, categorising SKUs into more granular inventory matrixes. These matrixes can either be kept very simple or have over 200 segments, as shown below.

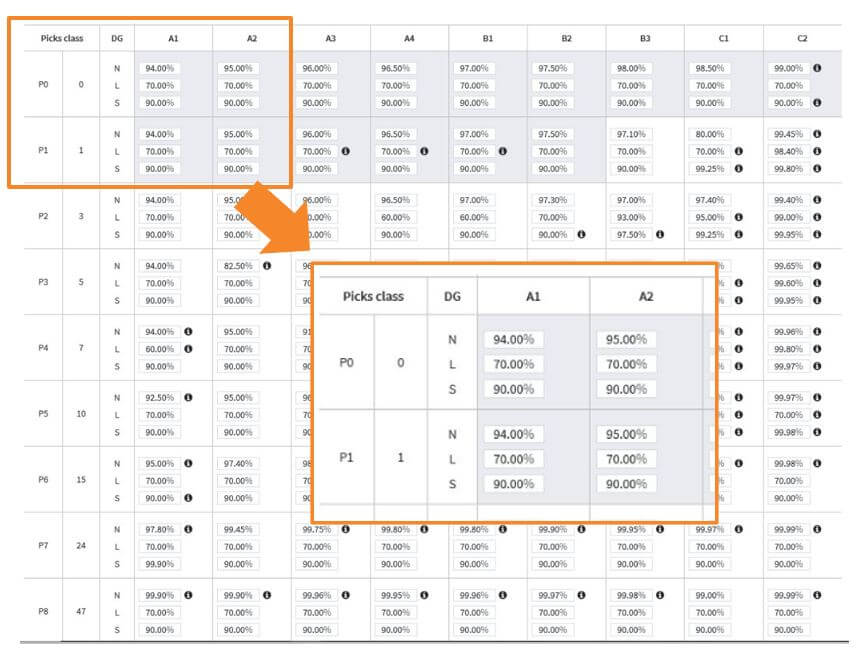

EazyStock then automatically applies stocking rules to ensure reordering parameters are set, and target service levels are achieved accordingly. As a general rule, this means items with consistent demand, high pick frequency, and low cost-to-sell will have higher stock levels to achieve higher service levels, whilst those that are expensive to stock, have a low pick frequency, and have more volatile demand will be stocked in lower volumes with lower service level targets to meet.

Every day, EazyStock dynamically moves items between categories and automatically updates stocking rules, as required. The result is that inventory levels are automatically optimised, allowing capital to be invested in the right stock and healthy turnover rates to be achieved.

Service levels and stock availability

Many businesses use service level KPIs to measure stock availability or order fulfilment. Inventory service levels are directly linked to customer satisfaction, e.g. if orders can be fully fulfilled, then customers are more likely to be pleased with their service experience.

Unfortunately, most ERPs, including Business Central, lack the functionality to measure service levels and track this important KPI. With EazyStock, however, target service levels can be set and measured at product group or even SKU level, allowing businesses to monitor stock availability and its impact on customer satisfaction more closely.

In EazyStock, service levels are usually configured during system implementation and assigned to segments of the inventory matrix. So, if high service levels are required, EazyStock will automatically adjust stocking rules accordingly to carry more of the items, and vice versa. In turn, these stocking policies inform the reordering parameters, with reorder points, quantities, and safety stock levels automatically adjusted to ensure the right amount of stock is ordered.

Strategic decision-making – scenario planning

Many businesses find it difficult to predict the impact that improving stock availability or service levels could have on their cashflow or, in contrast, how cutting their stock investment could affect fulfilment. EazyStock, therefore, has the built-in capability to simulate such scenarios, removing any financial risk and helping you make informed decisions before changing your inventory policies.

Automating stock classification with EazyStock

For organisations with a large or growing number of SKUs, it’s critical to optimise inventory levels so operational costs and cashflow can be managed effectively. To do this, businesses need to understand the make-up of their inventory and set policies that achieve high service levels with the least amount of stock.

EazyStock helps businesses make informed inventory management decisions. Whether you’re looking to increase turnover and free up capital or reduce stockouts and improve service levels, EazyStock has a wealth of features, in addition to Dynamics 365 Business Central, to help support your plans.

If you’d like to know more about how EazyStock can support your inventory management operations, please get in touch with our team today.