An overview of demand forecasting in Microsoft Dynamics 365 Business Central

Demand forecasting can be challenging for inventory planners, yet it’s critical to do a good job of ensuring that the right stock items are in the right place at the right time along your supply chain. Over-forecast, and you’ll tie up too much cash in excess stock and inflated carrying costs. Under-forecast, and you risk stockouts and delays to fulfilment.

Forecasting is made more complicated by using time-consuming, error-prone manual processes. Enterprise Resource Planning (ERP) add-ons, like EazyStock, can make it easier. With our ready-made connector available in Microsoft’s AppSource, it’s easier than ever to integrate EazyStock with the ERP to provide advanced inventory management capabilities.

In this post, we’ll review the demand forecasting capabilities of Microsoft Dynamics 365 Business Central and NAV and explain why it’s smart to use automation to make your forecasts as accurate as possible.

Microsoft Dynamics 365 demand forecasting

Using Microsoft Dynamics 365 Business Central demand forecast capability provides users simple demand forecasting functionality, very similar to most other ERP systems.

The ERP relies on users manually uploading sales or production forecasts. It then combines them with the relevant, pre-programmed reordering policies, e.g., Fixed Reorder Quantity, Maximum Quantity, Lot-For-Lot, and Order, which lay the foundation for stocking rules. Business Central then uses these rules to create reorder proposals to meet future demand.

The challenges of manual Business Central forecasting

Here are four key challenges businesses experience creating manual demand forecasts:

- Manually creating forecasts in spreadsheets is time-consuming and resource-intensive, particularly when you have an extensive product portfolio.

- Manual demand forecasts quickly become out-of-date and need regular updates to maintain accuracy, especially for items with volatile demand, seasonal profiles, and growing or shrinking sales.

- Even the best forecasting spreadsheets are prone to human error.

- Manual forecasts are usually based on previous sales history. While this method is suitable for inventory items with stable demand (where previous demand data is a good indicator of the future forecast period), in reality, very few items follow such simplistic logic. They usually experience a range of demand patterns and are subject to market trends, variances in forecast sensitivity, and seasonality.

EazyStock’s additional demand forecasting capabilities

Demand profiling

Connecting EazyStock to Microsoft Business Central or NAV, automates demand forecasting.

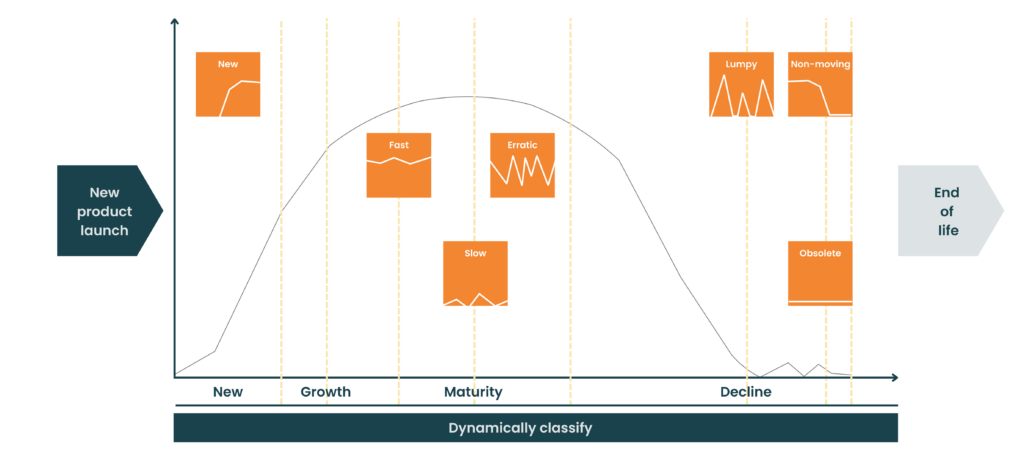

To produce a base forecast, EazyStock takes a data feed from the Business Central to analyse historical demand and classify items into one of eight different demand types, based on their position in their product life cycle.

For example, a product in its growth phase is likely to follow a positive demand trend as sales increase. Demand usually stabilises when it hits maturity, before becoming increasingly erratic and lumpy as it faces decline.

Demand types are important as they dictate which statistical algorithm EazyStock uses to calculate forecasts. As products move along their life cycle, EazyStock updates demand types and subsequent algorithms to maintain forecast accuracy.

Other factors affecting demand

With the base demand calculated, EazyStock then considers:

- Seasonality – adding seasonal demand profiles helps prevent shortages during peak seasons and expensive surpluses as demand tails off.

- Trends – trends due to changes in consumer behaviour or tastes can be identified quickly and forecasts adjusted accordingly for optimum reactivity.

- Promotions – special offers, discounts and long-term price drops can easily be manually added to the forecast.

- Forecast sensitivity – EazyStock can be configured to weight forecasts on more recent demand data for fast-moving industries or extended historical demand periods for industries where trends change much more slowly.

Ensuring demand accuracy

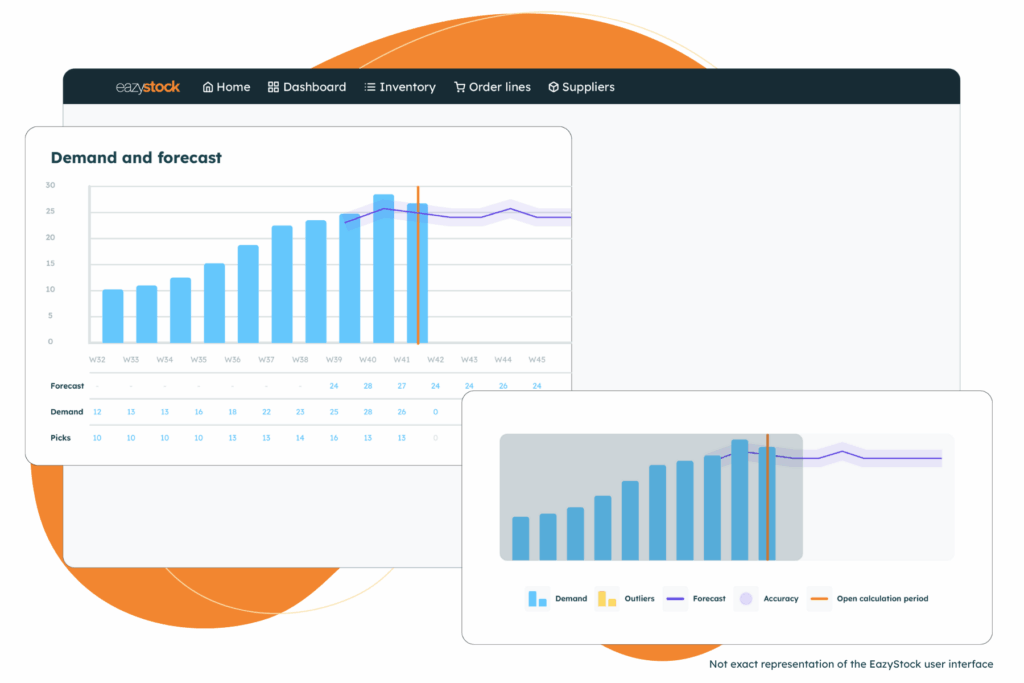

With data flowing daily from Business Central to EazyStock, items are re-analysed, and forecasts are updated to ensure they constantly react to market dynamics and consumer behaviour.

EazyStock also tracks actual demand throughout the forecast period and provides alerts when it deviates significantly from its projection. This allows the user to act on the intel and prevent potential stockouts or excess inventory buildup. At the end of a forecast period, it will also highlight extreme forecasting variances, e.g., demand outliers, so that the cause can be investigated and future forecasts adjusted accordingly.

Replacing Business Central and NAV’s forecasting and replenishment functionality

With forecasts created, EazyStock feeds these into dynamic stocking policies and reordering calculations to generate a list of recommended orders. These can then be reviewed and pushed back into Business Central for processing.

It’s time to automate demand forecasting

Essentially, EazyStock removes the need to create manual forecasts or use Microsoft’s sales and inventory forecasting module. Instead, it automatically generates projections using advanced statistical algorithms, ready to inform replenishment calculations and ensure reordering proposals mirror demand requirements.

However, EazyStock is more than just a demand forecasting tool; it also includes advanced inventory classification functionality and the ability to calculate reordering policies and planning parameters dynamically. Ultimately, the software removes all manual calculations associated with inventory planning and replaces the need for resource-intensive spreadsheets. Instead, inventory teams can manage by exception, saving time by allowing the system to automate regular orders and deal with system alerts and anomalies.

If you’d like to know more about how EazyStock can meet your demand forecasting requirements, please get in touch with our team today.