Firechief® Global reduces inventory value by 12% while simultaneously reducing stockouts

Firechief® (previously Sentura Group) has provided UK-approved commercial and domestic fire safety equipment for more than 60 years’.

You’ll doubtless have seen their products protecting various public buildings, factories and offices, as well as private homes across the UK.

The third-generation family run business headquartered in Rutland, in the East Midlands, is driven by a passion for making a difference to workplace and home fire safety. With a commitment to excellence, they operate a growing portfolio of products available for immediate dispatch from their global distribution centre in Birmingham.

The challenge

Managing a couple of thousand SKUs is no mean feat: you need the right data to ensure you’re stocking the right goods when needed. Firechief® knew what information they needed from their inventory management system, but its limited functionality made ordering the correct products difficult. When it came to demand forecasting, their reliance on historical demand data meant that even though they were struggling with stockouts, their inventory value was unnecessarily high.

With over 32 years of supply chain experience, Sean Hutchinson, Head of Supply Chain, knew it was time for a change. Sean wanted to enhance the functionality of their existing ERP system, Orderwise, by combining historical demand information with other data to highlight demand patterns and trends to provide more accurate forecasts.

Armed with more accurate information, Sean and his team could order the right products when needed to reduce stockouts and improve customer service.

The solution

Enter EazyStock and its team of inventory experts. The team took the time to get to know the Firechief® team and their inventory issues before demonstrating EazyStock’s key features that would help solve their supply chain challenges, such as:

- Easy integration with their Orderwise ERP system.

- Advanced forecasting algorithms that consider seasonality, trends and promotions, as well as multi-location forecasting.

- ABC-XYZ analysis to prioritise Firechief®’s most important stock.

- Automated replenishment calculations and daily order proposals, including safety-stock levels.

Then there was the piece de resistance – EazyStock’s unique Customer Success team. At EazyStock, all customers are allocated a Customer Success Manager who works with them from day one to get up and running and remains their go-to for anything they need.

Mark Chapman and Marek Glaszewski worked closely with Firechief® to get things set up and ready to optimise their inventory. Sean was happy to take advantage of Mark and Marek’s advice and training.

Both Sean and Megan Pollard, Supply Chain Co-ordinator, have been incredible in their desire to get the best out of EazyStock and take control of their stock.

“I’m a firm believer that when you have a system, you need the system to work for you. Mark and Marek made it easier for us, so we weren’t trying to work out the system and all these manual things.”

Megan agrees that it was important to get EazyStock’s help to ensure the right data was going in.

“We wanted the data to be as accurate as possible to reduce time spent on ordering. With a couple of thousand SKUs, there’s a lot of data to check and get right. With Mark and Marek’s support, we knew it was set up correctly.”

The results

One of Firechief®’s main objectives was to improve forecast accuracy to reduce stockouts, which they’ve achieved and more; as Megan highlights:

“Switching from the old system to EazyStock means we can forecast forward instead of just looking backwards. This means that ordering is much more accurate and suited to what demand actually comes through”.

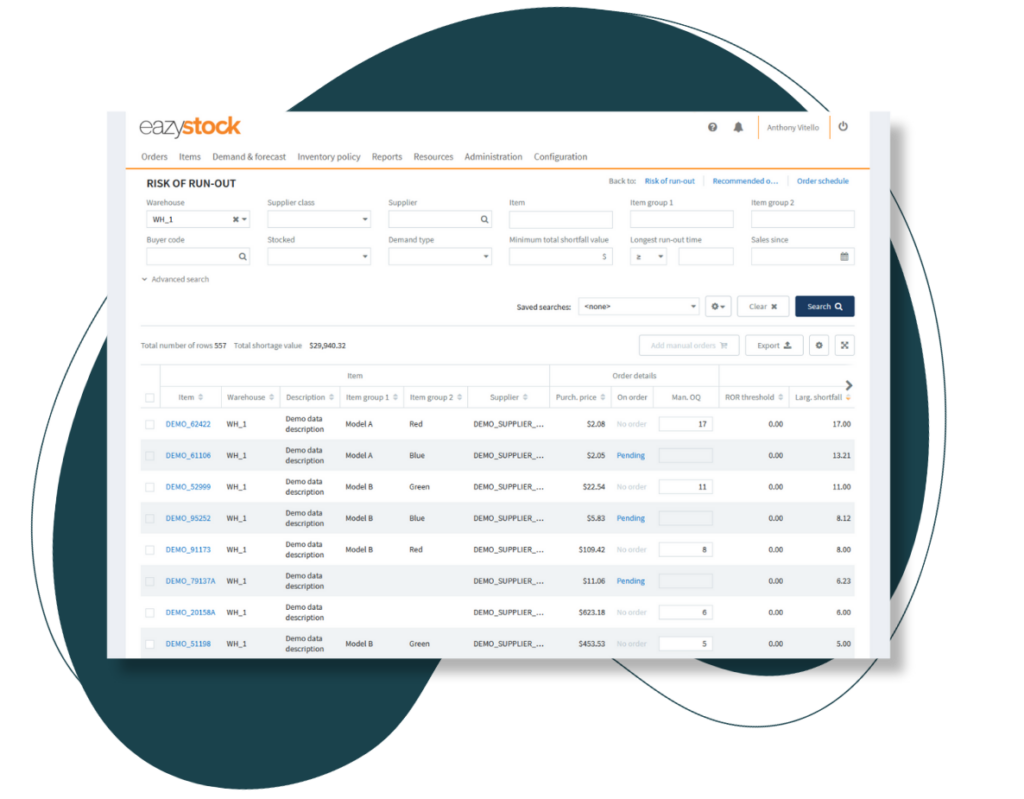

Firechief® are seeing some impressive results when considering risk of run out, out of stock, stock turn and inventory valuation:

- 77% reduction in items at risk of running out. The risk of run-out report has gone from showing around 48 SKUs to 11.

- Stockouts have almost halved, down to 4.5% from 8%.

- 33% reduction in stock days from around 221 to 148.

- 12% reduction in inventory value to around £2.2m.

EazyStock has also given Sean and Megan time back. They used to hold a weekly hour-long stock update meeting to review out-of-stock or at risk of going out of stock products. Megan explains that after dropping the meeting to half an hour, they’ve now dropped it altogether.

Firechief® are using EazyStock to support further changes to their inventory management policies, such as bringing in smaller containers more often to bring in less stock and increase stock turn. Whatever the container size, EazyStock’s order fill-up functionality makes it easier to fill shipping containers with items that will actually sell, not just fill empty space.

EazyStock’s recommended order screen and the ability to update supplier information, such as lead times, has gone from taking Megan a couple of hours a day to place and review orders to just a few hours a week. There are some suppliers that Megan knows she can accept immediately.

“This is great because it means that what the system suggests aligns with what we choose to order. Spending the time making sure our inventory policies and buffer stock levels are right was worthwhile.”

As EazyStock provides more accurate order recommendations, Firechief® have stopped the clock on ageing stock. Stock aged 0-3 months has increased from 83% to 91%, while stock aged 12-24 months has reduced from 7% to 1% and stock older than 24 months has fallen to only 2%.

Megan is finding the level of reporting that EazyStock provides invaluable. Taking the time to understand the reports has led to time savings and greater visibility for the supply chain team and the wider business.

“Reports are really useful, not just the risk of run out. We also use the excess stock report. As the reports are easy to understand, reporting to the managerial or director level is much easier. We’re likely to pull a lot of information from these reports and the summary page to show the team how we’re doing from a supply chain perspective.”

Sean agrees, “Before we’d say, that doesn’t seem right, or is that right? Now, we just say it will be right because instead of putting garbage in and getting garbage out, we’ve got more confidence because we’re putting quality data in, so the data coming out is accurate.”

When asked about the difference Mark and Marek made, Sean was full of praise. “Mark and Marek have been great. They’ve jumped on things at the drop of a hat, such as helping us create a customer report for the average stock days over the 12th period. It’s a really good report, which gives us a good ratio with gross profit.”

Mark emphasises the unique role the Customer Success team plays.

This is just the beginning for Sean and EazyStock. “It’s a continuous journey, and we don’t want to stop here. There are more benefits to come and more functionality we could use. As the business grows, we’ll adjust our inventory policies to ensure they’re still right and set up correctly for the business. That’s why having ongoing meetings with Mark and Marek is great because they can help us identify opportunities early and get the ball rolling.”

One thing that Sean can’t emphasise enough for companies considering inventory optimisation software is to invest the time at the start to get things set up properly. “If your data isn’t good, you don’t get good information out. Make the most of your customer success managers to get everything set up.

“As long as you’ve got a Mark and Marek (or any of the other customer success managers) on your side, you’ll be alright.”