Supply Chain Trends 2026

2025 review

If we’d hoped that 2025 would give purchasers a break from disruption, but geopolitical tensions persisted, with trade barriers, unstable tariffs, and changing political allegiances, it made for a tricky time and brought global economic instability.

Climate change continued to disrupt supply chains with extreme weather damaging infrastructure and increasing the risk of challenging sea conditions.

In October, the UN Trade and Development report highlighted the strain on supply chains. They indicated that maritime cargo routes are growing faster than volumes, and geopolitical disruptions, environmental pressures and digital risks are squeezing global supply chains.

Freight costs have become volatile, and longer routes are increasing carbon emissions at a time when climate change and sustainability are high on the agenda.

Supply chain and purchasing teams are in an impossible position. They’ve got pressure to cut costs on one side, while major supply-side disruption is necessitating larger-than-usual safety stocks.

Some of you will be glad to see the back of 2025 with all its challenges and constant tariff changes. Once again, we’ve reviewed reports and articles to look ahead at the supply chain trends you need to consider.

2026 preview

One thing is clear. Supply chain disruption isn’t temporary or a rare occurrence. Purchasers and supply chain managers now need to accept that disruption is the new normal. This means it’s essential that companies build resilient, robust supply chains that can withstand whatever the world throws at them.

You won’t be surprised to see some of the trends from 2025 carry over to 2026, starting with artificial intelligence.

Artificial intelligence

Last year, Supply Chain World and Supply Chain Today put AI in their top trends, and it’s sticking around. Where companies were starting to dip their toes into the AI water to gain insights, McKinsey says that “AI will move from insight generation to orchestrating outcomes, such as rerouting shipments and automating alerts.”

Procurements Tactics believes that AI is driving procurement toward complete digitalisation, stating, “By 2026, agentic AI capable of acting and making decisions on its own will help procurement teams analyze data faster and automate more tasks.”

StartUs Insights found that the cost of running an AI system has fallen while energy efficiency has improved by 40%, making AI more affordable for smaller businesses.

Supply Chain Management reported the Association for Supply Chain Management’s top 10 supply chain trends for 2026, which has AI as the top trend. By 2027, ACSM expects AI to be central to supply chain strategy and indispensable by 2032.

We’ve broken down AI and some inventory management applications in our eGuide, ‘What is Artificial Intelligence?’ to help.

Technology and supply chain digitisation

McKinsey predicts that digital twins will become the backbone of supply chain planning, allowing businesses to create virtual, real-time replicas of their supply chain to test scenarios and improve decision-making.

Dynamic Distributors believes we’ll see more automated guided vehicles (AGVs) and automated mobile robots (AMRs) to support warehouse operations, freeing up time for other tasks and enabling orders to be shipped more quickly.

Supply Chain Today thinks that digital supply chains will become the norm. As we discussed last year, automation will be key to improving supply chain efficiency and boosting profitability.

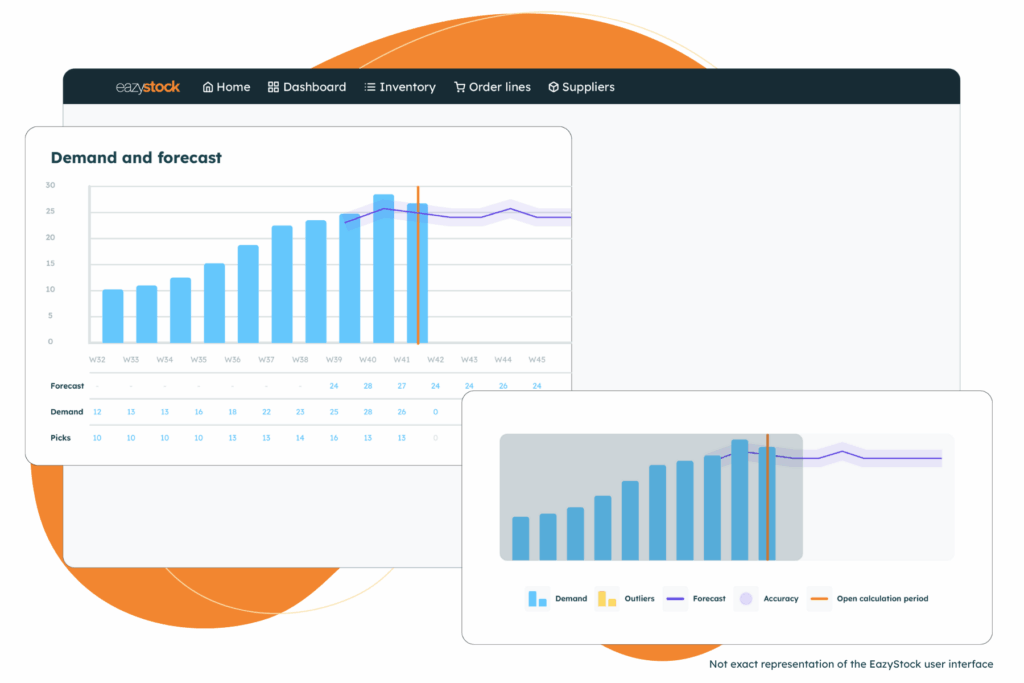

Connecting your ERP system to cloud demand forecasting and inventory optimisation software increases supply chain visibility by providing more information. With more information, you can make data-driven decisions to respond to market trends and changing economic conditions regarding stock levels and operating costs.

The Internet of Things will continue to develop, enabling businesses to track goods and items through the supply chain by connecting devices and objects to a digital network.

Connecting items using sensors and tracking devices such as NFCs, QR codes, barcodes, and tags means you know exactly where your items are, what condition they’re in and when to expect delivery. With this level of visibility, you can anticipate and respond to issues faster, reduce administrative time and reduce the risk of theft or lost items.

Digitalising your supply chain can reduce your environmental impact by lowering excess stock and minimising waste, thereby positively impacting your bottom line. By optimising your inventory thanks to more accurate demand forecasts and smarter ordering, you can ensure you hold the stock you need and reduce the need for rushed air orders.

With more data at your disposal, you can share consistent order information so they can combine your orders into batches, reducing the number of shipments you receive. You’ll also be able to meet minimum order quantities efficiently and make the most of space in shipping containers for goods with upcoming demand.

Cybersecurity

The UK was hit by a record number of cyberattacks in 2025, bringing major companies to a standstill. Marks & Spencer, the Co-op, Mailchimp, HubSpot and Jaguar Land Rover all fell victim to attacks.

If the biggest brands are vulnerable to cyberattacks, you must have robust plans to prevent them. If you are susceptible to an attack, your response needs to be swift and efficient. You also need to think about your supply chain. What would happen if one of your customers who places frequent, large orders with you were attacked and couldn’t place any orders for a sustained period? How would that affect your business? What contingency plans do you have? The same for your suppliers – if they are attacked and cannot provide the items you need, how will you deliver goods to your customers?

ACMS warns that as digitisation has created more connectivity, it’s created more openings for cyberattacks, and that “We will have to make sure that the entire link doesn’t have weak spots.”

You can find more information about cybersecurity in our blog ‘Supply chain cybersecurity: 5 ways to minimise threats. We also have blogs that cover information security and ISO 27001 in more detail.

Supplier location strategies

As we move into 2026, Procurement Tactics predicts a shift from globalisation to regional resilience. “Companies are moving production closer to where demand is, through nearshoring, reshoring, and building regional hubs.”

Sustainability

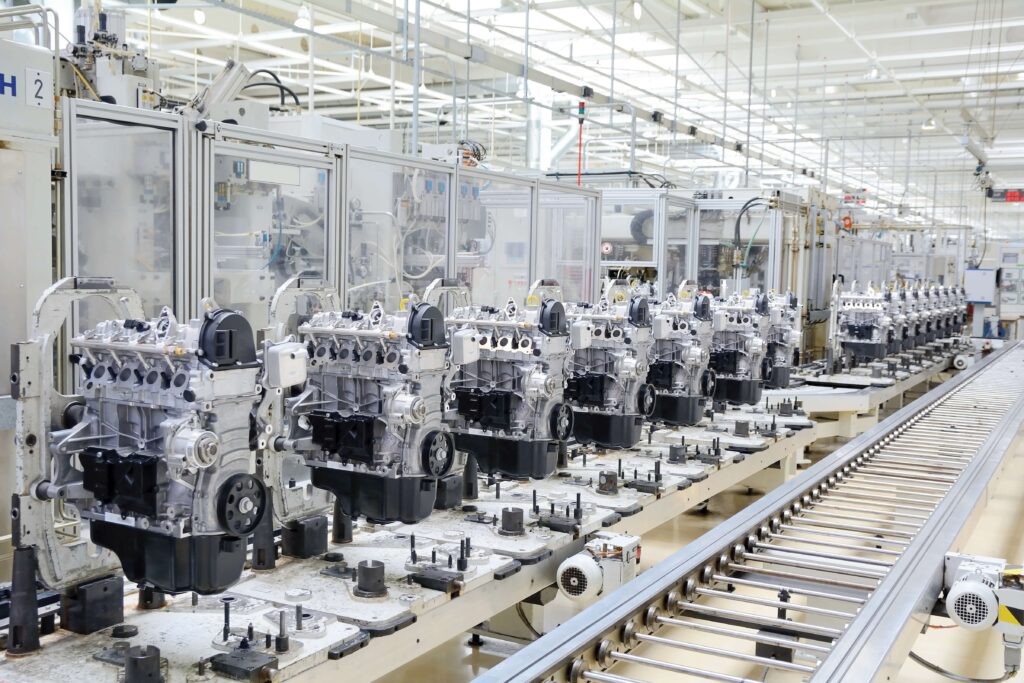

There are many ways for businesses to build sustainability into their supply chain. We’ve talked about sustainable supply chains, the circular economy, ethical sourcing and waste reduction before. Along those lines is remanufacturing, which McKinsey discusses in its podcast. “By extending the life cycle of some of their products, companies have been able to cut costs, strengthen supply chains, satisfy customers, and advance their sustainability goals.”

McKinsey also discusses the realities behind the push for sustainable packaging and the complexities of balancing meeting customer needs with the concerns of shareholders and employees.

Dynamic Distributors explain that a well-prepared business will be a strong business, ready to respond to the impact of climate change. They also explain how a sustainability focus will cut waste and avoid unnecessary costs.

ACMS feels that “climate and circularity are no longer optional initiatives.” However, they do warn that sustainable compliance is complex due to inconsistent standards. “Every company has a different metric. We need consistency. We do not do well with uncertainty and lack of consistency.”

Geopolitical dynamics, strategy and resilience

ACMS ranked trade policies and global dynamics second on their trends list, driven by uncertainty around international trade and tariffs. “It’s harder to get tariffs abolished because we haven’t seen this kind of situation before. Some organisations have to act quicker. In Brussels, we had a firm that imported wood from Canada to make furniture in Vietnam and then imported back into the US, and they were devastated by the tariffs.”

In a recent report, Maersk gathered insights from over 900 companies across Europe that were feeling continued strain on supply.

Over 78% of supply chain professionals surveyed anticipated that geopolitical dynamics, trade tariffs, and international trade regulations would impact their operations over the next one to two years.

Nearly half (48%) expressed deep concern about the geopolitical climate, and 4 out of 5 recognised supply chain challenges as a factor impacting their business growth.

Procurement Tactics explains that “Procurement professionals now face the challenge of moving beyond short-term crisis management.”

Building a resilient supply chain will be key to overcoming future challenges. A resilient supply chain incorporates supplier location and diversification strategies, supply chain digitalisation, and inventory and capacity buffers, as well as inventory management strategies. We cover these in more detail in our Building a resilient supply chain eGuide.

EazyStock

At EazyStock, we help customers navigate supply chain challenges with ease by optimising inventory through intelligent, data-driven decisions, driving efficiency and improving resilience.

Artificial intelligence

EazyStock’s AI-powered inventory optimisation software uses advanced artificial intelligence, machine learning and optimisation technology to improve demand forecast accuracy to minimise capital investment in unnecessary inventory, and boost product availability.

EazyStock’s machine learning algorithms consider historical sales and purchasing data, trends, seasonality, and product lifecycles to avoid stockouts, minimise waste, and cut unnecessary supply chain costs.

Technology and supply chain digitisation

Connecting your ERP system to EazyStock automates purchasing, saving time and balancing stock levels. It increases supply chain visibility, enabling data-driven decisions to respond to market trends and changing economic conditions regarding stock levels and operating costs.

Cybersecurity

At EazyStock is part of Syncron, our information security management system is ISO 27001, ISO 27017 and SOC-2 Type-2 certified. All data centres have SSAE 18 Type 2 attestations and ISO 27001 certifications to support business and service continuity, and include full redundancy (N+1) and fault-tolerant infrastructure for electrical, cooling and network systems. We also replicate our production database servers in near real-time to multiple availability zones.

Supplier location strategies

EazyStock will analyse lead times and item costs to find the most efficient supplier for your order. It also helps track on-time, in-full deliveries to identify underperforming suppliers. This data shows which regions are struggling to meet lead times and where it would be helpful to find alternative suppliers.

Sustainability

As a data-driven software solution, EazyStock harnesses historical and near real-time data to analyse trends, forecast demand, and optimise stock levels. This reduces stockouts, packaging waste, and the carbon footprint by combining orders and filling shipping containers smartly, reducing shipments and freight. By increasing the number of on-time, in-full orders, backorders are eliminated, saving packaging and reducing emissions.

Geopolitical dynamics, strategy and resilience

EazyStock can help with short-term and long-term strategies to respond to supply chain disruptions. From prioritising orders based on upcoming demand and lead times to ensure you maintain supply, to increasing inventory visibility and implementing inventory management buffers.

Further information

To learn more about how we can support your digitisation, automation, and AI plans, contact our experts, who will be happy to help.

If you have no idea where to start with managing your supply chain in 2026, then let us have a look at your data for free. We’ll conduct a free stock health check and let you know where you can make quick improvements to improve stock levels and save money.

Sources

- https://unctad.org/news/global-supply-chains-under-strain-ministers-call-just-and-resilient-transitions

- https://www.maersk.com/news/articles/2025/11/11/maersk-survey-4-in-5-supply-chain-leaders-expect-disruptions-to-continue

- https://www.mckinsey.com/capabilities/operations/our-insights/transforming-procurement-functions-for-an-ai-driven-world

- https://www.mckinsey.com/industries/automotive-and-assembly/our-insights/remanufacturing-turning-old-parts-into-new-opportunities

- https://www.mckinsey.com/industries/energy-and-materials/our-insights/blog/the-push-for-sustainability-packaging-is-real-and-complicated

- https://www.mckinsey.com/capabilities/sustainability/our-insights/sustainability-blog/circularity-the-strategic-path-to-sustainable-materials-and-cost-savings

- https://www.mckinsey.com/industries/metals-and-mining/our-insights/aligning-the-value-chain-to-decarbonize-plastics

- https://cloudandmore.co.uk/biggest-uk-cyber-attacks-2025/

- https://www.dynamicdis.com/post/inventory-management-trends

- https://www.startus-insights.com/innovators-guide/future-of-supply-chain/