ERP Inventory Management: The Ultimate Guide

What is ERP inventory management?

Many organizations have an enterprise resource planning (ERP) system to collect, store, manage and interpret data from a host of different businesses processes. ERP systems typically allow companies to undertake tasks such as purchasing, production planning, service delivery and customer management – all from one single platform. When it comes to inventory management, ERP systems are ideal for tracking stock along the supply chain, monitoring stock levels and order processing.

ERP inventory management limitations

Inventory management teams will begin to see limitations with their ERP system when they want more sophisticated inventory optimization solutions. This can include statistical demand forecasting, advanced inventory planning and automated replenishment activities. Oftentimes inventory planners will resort to using spreadsheets to carry out such activities due to the limitations of their ERP inventory management modules. But spreadsheets can be time consuming to set up and manage, and the risk of error is very high.

More and more businesses are therefore turning to inventory optimization software to provide these capabilities. To remain competitive they know they need the tools to ensure the right stock is in the right place at the right time. Can you recognize the warning signs that your business needs automated inventory planning and replenishment?

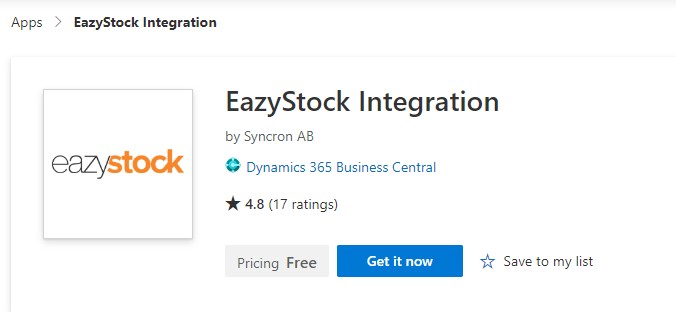

Inventory optimization ERP add-ons, such as EazyStock, can be easily linked to your business system to provide additional, sorely-needed features. By doing so, they can save you time and money in many ways that you may never have considered.

ERP inventory management needs sophisticated demand forecasting

Many ERP inventory management modules offer some demand forecasting functionality, usually based on basic, linear rolling average calculations, but these methods cannot take into account of typical causes of demand volatility. In comparison, an inventory optimization app will consider:

Product life cycle:

As a product moves through its product life cycle, from market introduction, to maturity and decline, it’s demand patterns will also change. For example, at maturity, demand may be stable, whereas when a product comes nearer to the end of its life, demand could become very volatile. In each scenario the demand patterns of one product can be very different to the next, and so the approach taken when forecasting demand should reflect this. Systems, like EazyStock, analyze historical demand data to identify each SKU’s ’demand type’ and then use the most effective statistical algorithm to achieve the most accurate demand forecast.

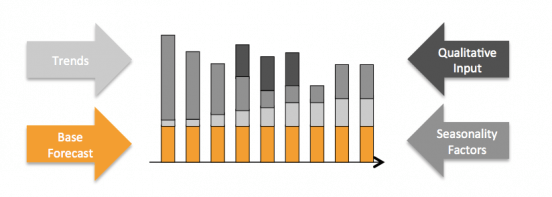

Seasonality:

The demand of seasonal products will obviously rise and fall. It’s therefore critical for inventory managers to identify demand peaks to capitalize on sales opportunities and spot the troughs to prevent a build-up of stock. An advanced inventory management ERP add on will analyze historical demand to identify these seasonal patterns, group products accordingly and account for seasonality when forecasts are created.

Trends:

Many items will experience demand trends. They are often most prominent when goods are either new to the market, coming to the end of their product life cycle or heavily influenced by fashion or technology etc. Again, inventory optimization software will identify these trends and account for them when forecasting future demand.

Promotions:

Qualitative information regarding sales promotions, discounts and competitor information can all be added to EazyStock to improve demand forecasting accuracy.

EazyStock’s algorithms are designed to recognize demand types, seasonality and trend patterns, adjusting forecasts on a regular basis, which in turn update your replenishment recommendations. As a consequence, you’ll always be able to make the most of demand surges and prevent costly stockouts and backorders.

Does your ERP optimize your inventory levels?

A key challenge for many stock holding businesses is how to lower their inventory levels without affecting their fulfillment rates and increasing the risk of stockouts. Many ERP inventory management modules lack the necessary analytical tools to recommend what and how much stock you should actually carry. At best they offer simplistic inventory classification calculations, based around principles such as ABC analysis.

An inventory optimization app offers advanced inventory classification that categorizes stock items based on:

- The value of annual usage (VAU) of each SKU. This takes into account sales volume as well the unit cost of the product.

- How often each SKU gets picked. This distinguishes high volume products with many requests (1000 requests for 1 unit) from high volume products with low requests (2 requests for 500 units).

- The demand volatility of each SKU. EazyStock automatically segments items based on their demand volatility behavior and, therefore, how easy their demand is to forecast.

Using these variables, EazyStock creates inventory policy matrixes with varying stock/no-stock rules in each one. These provide a much more detailed level of inventory classification, allowingbusinesses to make more informed stocking decisions than if they were using a simple ABC classification framework.

By optimizing your stock levels based on their demand, cost and pick frequency, you can improve inventory turnover rates, free up working capital and reduce your carrying costs. At the same time, you’ll be safe in the knowledge that your stock levels are optimized to meet customer demand with a low risk of stockouts.

By optimizing your stock levels based on their demand, cost and pick frequency, you can improve inventory turnover rates, free up working capital and reduce your carrying costs. At the same time, you’ll be safe in the knowledge that your stock levels are optimized to meet customer demand with a low risk of stockouts.

Most inventory optimization add-ons will then set target service levels for each SKU in your portfolio. Service level is an important inventory management key performance indicator (KPI) that shows how well demand is being fulfilled by your available stock.

Critically, the system allows you to find the right balance between the capital you have to invest in stock versus your service level (fulfillment) targets. This allows you to make more informed decisions about the stock you hold and how it will affect your service levels.

Automated replenishment is critical to ERP inventory management

Traditional WMS and ERP inventory management modules often use rule-based methodology to calculate replenishment. This approach can lack the level of sophistication and accuracy required by many businesses. They therefore result to manual calculations and spreadsheets that are time-consuming to manage, prone to errors and lack scalability.

A key benefit of EazyStock is its ability to automate replenishment tasks and improve the productivity of your inventory planning and purchasing teams. This prevents a lot of wasted time working out what, when and how much stock to reorder.

EazyStock constantly analyzes and evaluates a wide range of market and business variables such as demand, supplier lead times, current stock levels, stock in transit and your target service levels. This data is then used by advanced statistical algorithms to calculate your replenishment needs, such as your optimal safety stock levels, reorder points and reorder quantities. This is a perpetual process so that your ERP always receives optimized replenishment recommendations. The aim is to ensure you always have adequate stock levels to achieve your target service levels without over-investing in unnecessary inventory.

As an EazyStock user, you’ll receive an automated daily list of recommended orders. It’s then your call whether you want to approve every replenishment order or simply manage by exception and only review those that carry most risk.

With no more spreadsheets, inventory management teams will save time and resources, so they can focus on strategic decision-making and value-adding tasks.

How well does your ERP inventory management tool manage your suppliers?

It can be challenging for organizations to keep track of their suppliers’ lead times and make sure they don’t negatively impact replenishment schedules.

EazyStock therefore has functionality to upload your ‘supplier calendars’, so it can automatically factor these into the replenishment calculations for each SKU.

For example, if you only place an order with one particular supplier once a month, EazyStock will adapt your order quantities for all relevant items accordingly. Or, when holidays such as Chinese New Year come around, it will allow for these supply delays and adjust your reorder points and quantities to reduce the risk of stockouts occurring.

Cost-efficient ordering

Your ERP inventory management system will no doubt be automating the ordering of your stock, but can it ensure you’re always placing the most cost-effective order quantities?

For example, EazyStock can automatically identify items that are most suitable to add to an order to reach minimum order quantities or fill up shipping containers. The result is that you can quickly fill your orders with items that have demand (either now or in the near future) instead of unwanted stock that may end up sitting in the warehouse.

Or, if you have more flexibility with your suppliers, EazyStock can help you determine whether a large order at a lower ‘price per unit’ will actually save you money versus purchasing smaller quantities more frequently.

By always suggesting the most cost-effective purchasing strategy, EazyStock can help you reduce your operational costs, as well as ensure stock availability.

Enhanced ERP inventory management functionality

A simple inventory management ERP add-on can offer a wealth of value-adding functionality. Critically, it can allow you to drive down stock investment while improving service levels and product availability. The benefits have implications across your entire supply chain.

A key advantage of EazyStock is how quick and easy it is to implement. As a cloud-based ERP application it can be linked to your business system very easily. We then configure it’s parameters to your business’s needs and train your team – so you’re up and running in a matter of weeks.

If you’d like more information on how EazyStock can enhance your ERP’s current inventory management capabilities, please call our team at +1 (844) 416-5000 or contact us here.