Network Demand and Inventory Balancing In A Economic Downturn

The right purchasing and logistics strategies give companies an edge during these unique, uncertain times and, during the return “to normal,” a greater competitive advantage and continued growth.

As the global world economy has continued to recover completely from the aftermath of the Covid-19 pandemic, and with a subsequent war with Russia’s invasion of Ukraine and rising inflation, many stock-holding companies are having a hard time.

Rapid cost increases, interest rate hikes and reduced demand require more effective inventory management and forecasting attention. Regardless of how the next few months unfold, volatility in demand, inflation and uncertainties will affect stock-holding companies.

However, this time can also be seen as an opportunity for organizational change. With the right strategies in purchasing, logistics and supply chain, you can navigate through a recession and come out as a winner. Winston Churchill once said, “never let a good crisis go to waste”, which feels highly relevant when turning times of crisis in your favor.

In this article, we will show you some of the most important steps and measures to equip your organization for an economic downturn and create opportunities to flourish even during an economic downturn.

What the last recession taught us

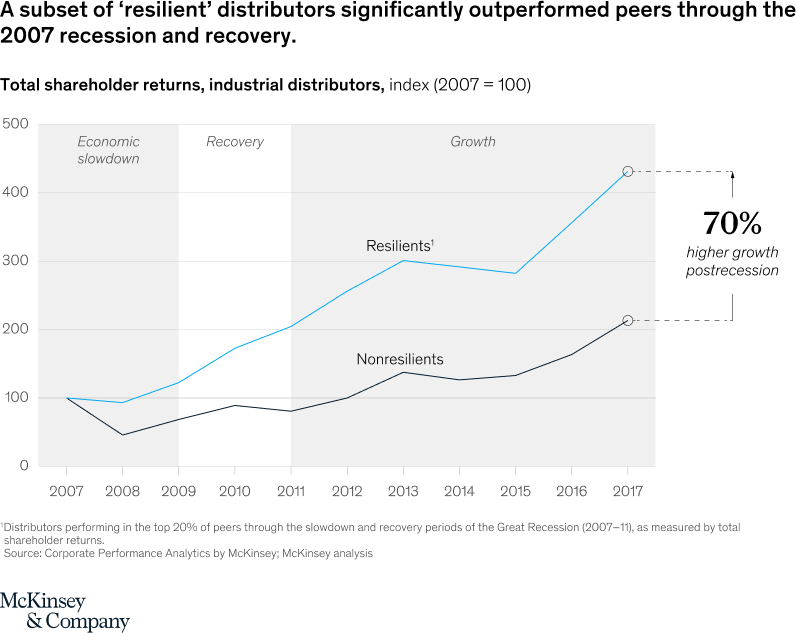

An article from McKinsey & Company (2022) analyzed the performance of about 40 publicly traded distribution companies during the 2007-2009 recession. It found that 20% outperformed competitors’ results during the downturn and recovery.

The distributors who gained a significant strategic advantage over their competitors had a laser focus on profitability during the downturn, a strong emphasis on margin management through disciplined pricing and category management, careful control of costs, and finally, the willingness to invest in priority growth opportunities.

4 Tips for stock-keeping companies during an economic downturn

1. Eliminate unnecessary inventory costs and reduce inventory values

All companies have different conditions (and challenges), and there’s no one-size-fits-all solution. Eliminating unnecessary inventory costs paves the way for removing risks and frees up working capital for other strategic priorities.

There are several advantages to keeping inventory costs down and lowering inventory value. First, it reduces direct costs such as storage, management, insurance and inventory maintenance.

Secondly, it increases liquidity as stocks require capital. You must sell goods within a specific timeframe to avoid negative cash flow and maintain a healthy financial position.

Finally, holding too much stock can lead to writing off goods at a loss if they don’t sell and become obsolete.

Keeping inventory costs down also provides direct competitive advantages, such as keeping lower prices, which can lead to increased demand and higher sales. Lower inventory costs also allow your company to be more flexible and quickly adapt to changing market conditions or changes in demand.

Finally, eliminating unnecessary inventory costs may allow you to reinvest capital in other strategic projects such as targeted sales activities or digitalization projects.

2. Digitize and automate as much as possible

A modern business system (ERP) provides almost real-time insights to streamline processes and data management across your organization. Many business systems also include functionality to support certain inventory management and purchasing processes. However, most businesses need more advanced and customized systems, such as a warehouse management system (WMS) or inventory optimization software. These can improve picking accuracy, inventory flexibility, security, and customer service.

Investing in the right software will provide the necessary information to perform more efficiently and make informed decisions.

Inventory optimization software improves your inventory availability, increases efficiency and balances inventory levels with capital expense to ensure you can meet customer demand. EazyStock is an inventory optimization system that automates forecasting and purchasing processes, making it easier to get more accurate forecasts to plan and order the right amount of each stock item.

By automating forecasts and order quantities, you receive reliable forecast data to more easily maintain optimal inventory levels. Holding the right amount of items when needed enables cost savings by reducing manual work and stock holding costs, and maintaining a high service level.

Inventory management systems increase the accuracy of inventory management and automate the work processes required to manage items well in the warehouse. Bitlog is one example of a WMS system that supports the daily activities of the warehouse, focusing on inventory control and the movement of goods in the warehouse. Combining the functionality of inventory optimization software with that of a WMS system provides complete control of your inventory levels and improves efficiency.

There are significant gains in digitizing manual warehouse processes, even during times of economic downturn. It saves time and money, optimizes processes and allows you to direct more resources to other operational priorities.

3. Create strong supplier relationships and eliminate risks

Once you’ve eliminated unnecessary costs and digitized manual processes to free up more time and capital, you should look to safeguard your supplier relationships and partnerships.

Strong supplier relationships are vital to ensuring your supply chain is cyclically secure. Ensuring continuity of deliveries depends on good communication between you and your suppliers. A reliable supplier network is also fundamental to ensuring you have the right stock to meet customer demand even in times of crisis. Many companies are reviewing their supplier network to highlight inefficiencies and identify ways to minimize risks during supply disruptions.

It is essential that suppliers share information about current and future risks with you, such as their dependence on their suppliers. This helps you map risks at each level of your supply chain. This mapping also highlights potential bottlenecks during an economic downturn and provides collaborative opportunities to prevent them.

If you haven’t already, start by assessing how critical each supplier is to your organization, and make sure you repeat this process regularly. Other supplier assessment metrics include how much you spend on each supplier, whether orders arrive on time and are complete, their cybersecurity, financial situation, lead times, unit prices, and minimum order quantities (MOQ).

Finally, working with suppliers ensures you receive goods on time and negotiate better prices. An effective way to do this is to leverage the forecasts from your inventory optimization system so that suppliers see your upcoming order and become more willing to adjust their terms and pricing.

4. Create synergies across your business processes

For stock-keeping companies, times of economic downturn can be extra challenging, but there are opportunities to emerge victorious by creating synergies between business processes. By leveraging modern technology and smart tools such as ERP, WMS and inventory optimization systems together, you can efficiently reduce your inventory costs and gain complete control over your inventory.

Each recession is unique and different from the previous one and affects companies differently, so you must navigate based on your conditions. That said, “business as usual” is probably a bad strategy. Inventory optimization software, like EazyStock, can give you the best of both worlds – reduce inventory costs and ensure you have the right products while increasing your service levels.

To be one of those companies that outperform their competitors and emerge victorious from an economic downturn, book a demo to learn more about how EazyStock can help.