Medical Equipment Fulfillment Challenges and Solutions

It’s no secret that the medical industry is facing major challenges worldwide due to Coronavirus. Medical and healthcare workers are stretched thin and at risk of infection themselves. Money and resources are tight. From manufacturing all the way through the supply chain to user, medical supplies have particularly been affected in terms of both demand and availability.

The most notable change has been the surge in demand for supplies like personal protective equipment (PPE) including face masks, face shields, disposable gloves, gowns, etc. along with things like ventilators and test kit components. The supply for equipment needed to fight Coronavirus and protect it from spreading further has been in high demand for months and shows no sign of stopping.

But the demand for other medical supplies has dipped considerably, especially for supplies needed for elective procedures and for treatments that can be safely postponed. Doctors and patients don’t want to risk infection, so the demand for these procedures has dropped – and the demand for the supplies has correspondingly dipped.

But the demand for other medical supplies has dipped considerably, especially for supplies needed for elective procedures and for treatments that can be safely postponed. Doctors and patients don’t want to risk infection, so the demand for these procedures has dropped – and the demand for the supplies has correspondingly dipped.

Finally, on top of these wild demand changes, sourcing has become a new challenge. Demand has surged around the globe – putting a lot of pressure on suppliers. Governments, distributors and now even companies and hospitals are looking for any way to get their hands on the equipment they need. Suppliers are under a lot of stress. Plus even moving goods has become more difficult, with 3PLs and delivery drivers overloaded and international freight backed up.

It’s an overwhelming time for manufacturers and distributors in the medical supplies industry, and no area of the supply chain will be restored to normal anytime soon. So what can you do to make sure your company stays afloat throughout Coronavirus and beyond?

Dealing with increased demand

For manufacturers and distributors facing an increase in demand from your customers, it can be difficult to fulfill every customer order. This can be even more difficult if the orders include SKUs that are currently challenging to get from suppliers. While fulfillment will not be perfect right now, there are some measures you can take to ensure that you fulfill as many customer orders as possible.

Identify high-demand SKUs

Success starts with identifying which SKUs are suddenly in high demand so that you can take action quickly. Now that we’re a few months into the pandemic and stricter regulations due to Coronavirus, it’s easier to identify which SKUs are in higher demand. But it’s important to keep an eye on these SKUs and to watch for demand surges for other SKUs as they deviate from their typical (that is, non-pandemic) demand.

This can be difficult to manage with an Excel spreadsheet or just an ERP. An automated inventory optimization solution like EazyStock will be able to flag SKUs that are deviating from normal demand and send you an alert so you can add what you need to your inventory.

Accurate inventory overview

Once you’ve identified the high-demand SKUs, the next step to success is knowing exactly how much inventory of each high-demand SKU you have and where it is located. Knowing what you have on-hand and where will help you better fulfill the orders you already have while helping you gauge what to reorder and when.

The challenge here is keeping an eye on your inventory levels as it goes out more quickly than usual. You don’t want to reorder too late and miss out on fulfilling orders to customers. Added to the rest of your inventory management responsibilities and the need for precision and accurate timing, it’s easy to let this slip. Automated software will keep an eye on your inventory levels for you and alert you with a Risk of Run-out report so you know when it’s time to reorder. The software automatically takes inventory levels, lead times and demand into account so you always have what you need on your shelves.

The challenge here is keeping an eye on your inventory levels as it goes out more quickly than usual. You don’t want to reorder too late and miss out on fulfilling orders to customers. Added to the rest of your inventory management responsibilities and the need for precision and accurate timing, it’s easy to let this slip. Automated software will keep an eye on your inventory levels for you and alert you with a Risk of Run-out report so you know when it’s time to reorder. The software automatically takes inventory levels, lead times and demand into account so you always have what you need on your shelves.

Dealing with decreased demand

On the flip side, manufacturers and distributors are facing decreased demand for specific items, especially for supplies for elective procedures. As doctors and patients are postponing procedures wherever they can to minimize the risk of Coronavirus infection, suppliers and distributors are finding themselves with stockpiles of supplies they can’t currently sell.

Identify excess stock & plan for the future

Typically, when companies find themselves with excess inventory, the best option is to try to sell as much as possible to free up capital and storage space. Often, they’ll run promotions or campaigns to accelerate sales. While this certainly remains an option, this may not currently be the best plan.

As restrictions ease, the demand for these elective procedures and other postponed procedures is increasing. While demand may not be at its previous levels yet, once Coronavirus has diminished, manufacturers and distributors can expect a surge in demand for the equipment and supplies for these procedures. However, that may still be a long time coming. The question to answer is whether it is more cost-effective to try and get rid of stock with currently low demand or to retain that inventory until demand is restored (and possibly even higher than before).

Reevaluate stocking policy

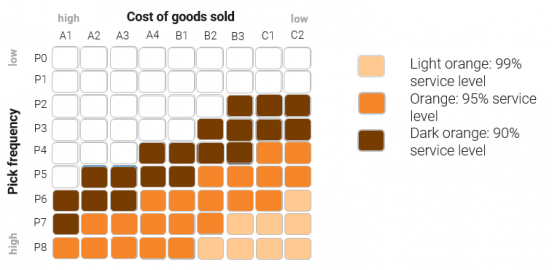

For companies facing diminished demand, it’s wise to minimize costs where you can. One way is to reevaluate your short-term stocking policy. According to the Pareto Principle, 80% of a company’s sales comes from 20% of the inventory. So how many SKUs within that additional 80% of inventory do you need to be stocking, and where can you stock less while still keeping customer service levels relatively high?

An inventory optimization solution like EazyStock will automatically analyze demand and prioritize SKUs. This will ensure that you know what SKUs and how much of each you need to keep on hand for your customers. Additionally, you can easily evaluate your stocking policy with the inventory policy simulation. This feature lets you choose which low-priority SKUs to stock less of and will relay a customer service level percentage that you’ll still hit. This way, you won’t sacrifice customer satisfaction and you’ll be able to free up capital and storage space.

Inventory Policy Matrix to determine Service Level

Difficulty sourcing from suppliers

Another major challenge facing the medical supply industry is having orders fulfilled by suppliers. There are a few reasons for this: suppliers are overwhelmed right now with high demand and new customer additions. There are also disruptions in freight transportation, which is trouble for international suppliers. A large percentage of international airfreight typically rides in commercial flights – and commercial flights are no longer happening at the rate they were. This causes a huge backup of goods. Finally, tighter regulations are putting a strain on the supply chain as well – especially regarding quality standards. Any goods that don’t pass inspection can’t be shipped out. So what can distributors do?

Prioritize your customers

Once you have an overview of your remaining inventory for high demand products, try to prioritize your customers. Fulfilling orders to clients who have a long order history with your company should take precedence, as you want to keep them as clients once normality is restored. Clients who have a strong need for your products should also be a priority – for example, hospitals treating patients with Coronavirus should be considered priority for PPE. Spreading your remaining inventory around as much as possible will also go a long way in customer satisfaction and proves that you are trying to take care of your customer as much as possible.

Source from new suppliers

While you wait on orders with now nearly impossible-to-predict lead times in your disrupted supply chain, you can be looking for new suppliers. While this will likely prove challenging, finding a local supplier could ease your supply chain disruption. This will also be a good practice in the future to mitigate supply chain disruption risk. A pandemic is not a usual type of disruption, but we can still expect natural disasters and even climate change disruptions in the future. Now is the time to create a more resilient supply chain.

Conclusion

The medical industry is facing unprecedented challenges. Demand for medical supplies has changed drastically while medical care providers are also facing some of their toughest tests yet. Hospitals and care facilities are losing revenue while acting as the front line to the Coronavirus pandemic. Manufacturers and distributors are likewise dealing with new supply chain disruptions and trying to provide essential equipment while trying to keep afloat. We all have to make the most out of the resources we have, and a little compassion goes a long way.