How to optimize inventory management for eCommerce

Better inventory management for eCommerce

The growth of eCommerce in 2020 was phenomenal as more customers, B2B and B2C alike, shopped online due to the COVID-19 pandemic. In Q3 of 2020 Amazon reported sales up 37% year-on-year, with eBay close behind at 25%. Forrester projects that B2B eCommerce transactions will reach $1.8 trillion by 2023, indicating a need for more robust online sales strategies.

With this global movement comes a wealth of opportunities for businesses, both large and small, to expand their reach and target new customers. But it also brings increased competition, with new players continually entering the marketplace and vying for a piece of the action.

For businesses to succeed in eCommerce they must ensure they have an effective eCommerce supply chain strategy. This means their supply chain operations must be as efficient at serving eCommerce sales channels as they are at fulfilling offline markets. A critical area of focus should be your eCommerce inventory management processes. Want to know how? Watch our short video and then read on…

Here’s how eCommerce businesses can improve their inventory management.

Improving your eCommerce inventory management

eCommerce Inventory Management is the business process responsible for ordering, managing, storing and moving inventory. As an element of supply chain management, inventory management supervises the flow of goods from manufacturers to warehouses and onto relevant eCommerce sales channels.

In contrast:

eCommerce inventory optimization is the art of predicting and managing supply and demand variables while undertaking inventory management processes. It allows you to manage your eCommerce inventory better by balancing capital investment and service-level goals with demand and supply volatility. The objective of eCommerce inventory optimization is to have the right products in the right place at the right time – as efficiently and cost-effectively as possible.

Here are ways you can optimize your inventory management practices for eCommerce competitiveness:

How to manage eCommerce inventory

1. Forecasting eCommerce inventory demand

The eCommerce marketplace is dynamic and demand can dramatically fluctuate up and down. Retailers and wholesalers therefore need to be agile enough to respond to any changes in customer demand – fast!

Simply reacting to market change is not enough, because you may have insufficient stock to meet a surge in demand or even miss out on a trend altogether. To be one step ahead, you need to be proactively anticipating fluctuations.

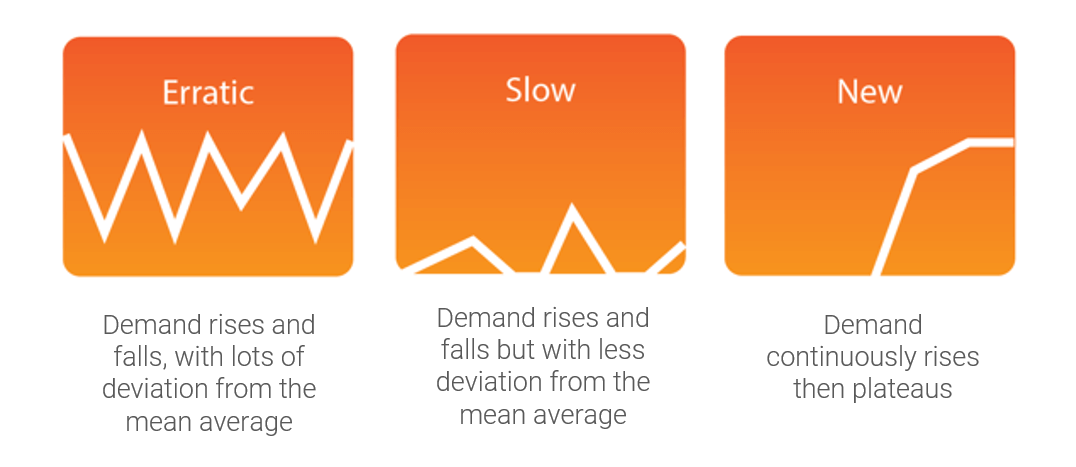

Using historical demand data alone is not enough to predict your future demand and prevent stock outs – especially when markets are unpredictable and you carry items with erratic and sporadic demand. Statistical demand forecasting is much more effective as it analyzes historical demand at SKU level and assigns a suitable algorithm to calculate demand based on the item’s demand patterns.

Statistical demand forecasting works because the demand for every item in your warehouse is not be the same. Each product will be affected by a different type of demand and have a different variance from their average demand. For example:

With such different demand patterns, it doesn’t make sense to treat every product the same. In each case the future demand forecasting, replenishment and safety stock calculations need to be treated differently. By doing so you can help prevent stock outs, as discussed below.

2. Seasonality, trends, promotions and new products

Seasonality, demand trends and promotional activity all impact demand and are important to add to a base forecast to improve its accuracy.

Seasonality: Understanding how the seasons or annual festivals like Christmas or Diwali impact product demand will ensure you don’t lose sales due to shortages during peak seasons or have expensive surpluses as demand tails off.

Trends: Whereas seasonality effects demand on a regular basis causing peaks and troughs, a trend will move demand in one direction over a period of time.

Promotions: In addition, promotional activities such as special offers, discounts and long-term price drops will impact the overall demand for your product.

In summary, demand forecasting helps estimate the future demand across all your eCommerce sales channels to ensure product availability and help drive customer satisfaction. Additionally, this information can be shared with suppliers to improve their service levels and help plan deliveries more strategically, helping improve the cost-efficiency of your supply chain.

3. Accurate eCommerce inventory replenishment

While it’s important to predict the future demand of inventory items, it’s equally critical to work out the most cost-effective means of fulfilling that demand. Many eCommerce organizations believe that they need to carry excessive amounts of stock to deliver high service levels. This is not true. Here’s why…

Inventory optimization techniques can help you calculate how much stock to order and when to order it, so you have enough to meet demand without tying up too much capital.

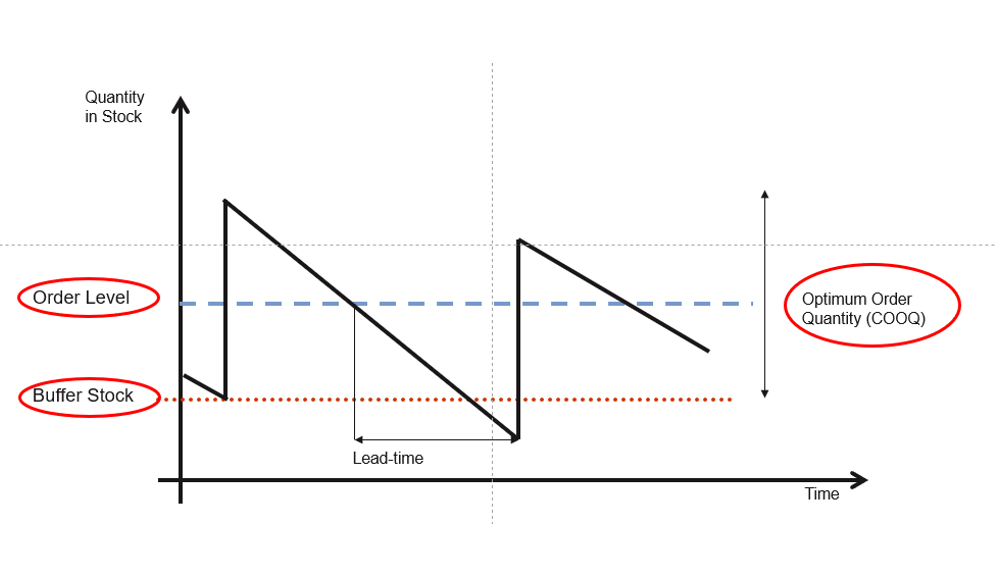

This is done by calculating accurate reorder points and quantities, and sufficient safety stock levels, so the risk of stock-outs is drastically reduced. The calculations can be quite complex, as they also take into account:

Service level – probability of not having a stock-out, or the probability of not losing sales e.g. a 95% service level target means you’ll fulfill 95% of orders.

Lead time – time it takes your supplier to deliver, from purchase order to stock in the warehouse.

Safety stock – stock used to cover any uncertainty in demand during the lead time.

Reorder point – point at which the order is placed.

Optimum order quantity – amount of items ordered, when taking into account the demand forecast, lead times and any supplier constraints e.g. number of deliveries per year, max/min order quantities.

The diagram below shows how these elements are related: By optimizing your replenishment processes, you can be sure that you’ll have the right products available to meet your expected demand while also carrying sufficient safety stock in case of unforeseen surprises. In addition, you’ll be able to do so without the cost of holding excess stock.

By optimizing your replenishment processes, you can be sure that you’ll have the right products available to meet your expected demand while also carrying sufficient safety stock in case of unforeseen surprises. In addition, you’ll be able to do so without the cost of holding excess stock.

4. Stock level optimization

So far we’ve shown how statistical demand forecasting and inventory optimization techniques help eCommerce businesses cost-effectively replenish stock to ensure that demand can be met. The final part of the jigsaw is knowing what products to hold in the warehouse.

Inventory classification models such as ABC inventory analysis allow you to group products based on their value to your business and turnover rate (how often they are picked). You can then define their corresponding service levels. The result is the creation of a matrix of stock items with varying stocking rules. For example:

- Fast moving, lower value items that have a high service level should be stocked well, as they are cheap to stock/sell and you want to ensure their availability.

- In contrast, high value items that are rarely picked may not even be stocked and will be fulfilled to order.

By setting stocking rules you can prioritize the items you hold in stock and free-up working capital to invest in other areas of the business.

Freeing-up working capital could be extremely useful for eCommerce companies looking to gain a competitive edge in the marketplace, allowing increased investment in marketing activity, new sales channels or new product lines.

Automating inventory management for eCommerce efficiency

By employing some of the inventory management techniques we’ve discussed above, you’ll be able to manage your eCommerce inventory more efficiently and cost-effectively, improving your competitiveness as you go.

However, implementing demand forecasting using algorithms and carrying out advanced inventory optimization calculations can prove complex and time-consuming, so consider the use of software to support. While some enterprise resource planning (ERP), warehouse management systems (WMS) and eCommerce platforms offer basic eCommerce inventory management functionality, investing in specialist inventory optimization software will ensure you have the tools you need for the job. Software like EazyStock is quick and easy to set up and will do all the hard work for you, so you have more time to analyze findings and make informed, strategic decisions.

For more information on EazyStock email us at info@eazystock.com or call (844) 416-5000.

First published on Nov 2017, updated Feb 2021.