Obsolete inventory management: the causes and cures

What is obsolete inventory?

Obsolete inventory refers to stock that has seen no demand for a prolonged period of time, e.g. it has not been sold to customers or used in production. This is usually because it has reached the end of its product life cycle. Obsolete stock is often a financial burden to businesses, as it usually has to be sold at a loss or simply written off at the end of a financial year.

Causes of obsolete inventory

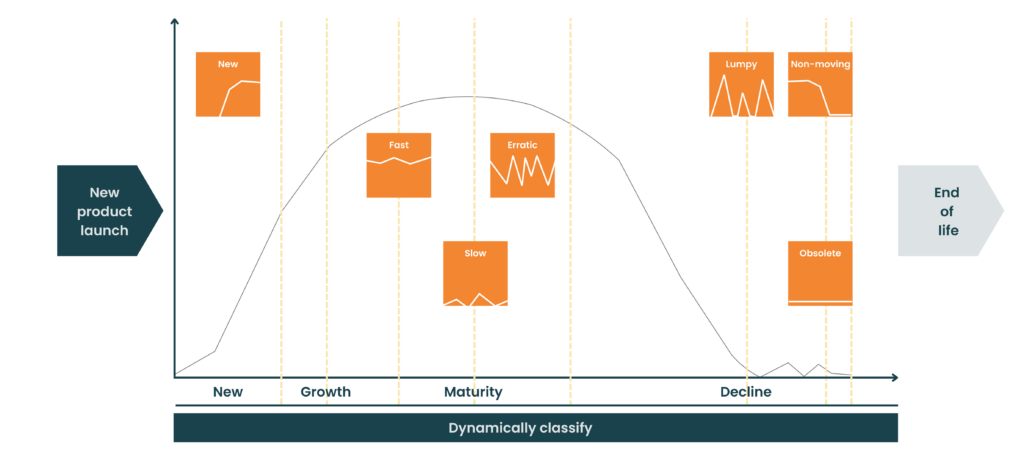

As an item reaches the end of its product life cycle, its demand will begin to drop off. In retail or wholesaling, this means sales will start to fall; in manufacturing, consumption will dry up; and in after-parts servicing, the part will no longer be ordered.

Some organizations classify these items as ‘slow-moving’. In reality, the pattern of demand could be negative (seeing a continuous decline in demand) or lumpy (with periods of low demand and periods of no demand), before hitting the stage of obsolescence.

The rate at which inventory items can turn obsolete will differ, depending on what the product is and its industry or marketplace. For example, in the high fashion and technology markets, tastes change quickly, with new products continuously replacing older models. Goods with a short shelf-life are also at higher risk of degradation and swiftly reaching obsolescence. Whereas in sectors with long-lasting machinery, for example boilers or cars, service parts may not become obsolete for many years.

Inventory obsolescence is often caused by businesses failing to understand the product life cycles of the items they stock and consequently missing the warning signs of those nearing their end. If they haven’t accurately forecasted a decline in demand or effectively adjusted their stock replenishment parameters, they will often be left with obsolete goods.

Inaccurate forecasting and poor inventory replenishment practices are key reasons for obsolete inventory. When a business is carrying excess inventory, e.g., more stock than demand requires, stock must be reduced accordingly. Otherwise, it will become obsolete if the items have no demand, deteriorate, or pass their sell-by-date.

Why is inventory obsolescence a problem for businesses?

While obsolete inventory remains in a business, there are a number of financial repercussions it has:

- It ties up working capital, which looks bad on the balance sheet and means it cannot be invested in other aspects of the business, such as marketing, recruitment, technology, or other inventory items.

- It uses up valuable space in the warehouse and increases all carrying costs.

- It affects inventory turnover ratio.

- It usually leads to stock being sold at a discounted price, e.g., a lower net resaleable value, or being written off altogether. Therefore, it hits a business’ bottom line at the end of the year, when the cost is usually absorbed in the Cost of Goods Sold on the profit and loss sheet.

For these reasons, it’s important to get rid of obsolete inventory as quickly as possible (see below).

Obsolete inventory management policies – KPI examples

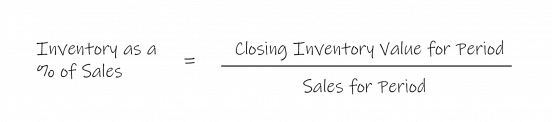

It’s important to keep track of your stock levels and look out for signs of inventory obsolescence. Possible inventory KPIs to use include monitoring your inventory turnover ratio or calculating

inventory as a percentage of sales.

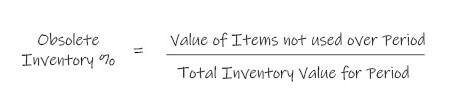

Some accounting principles also recommend calculating and monitoring your obsolete inventory percentage:

While caution needs to be taken as these calculations are simplistic (for example, they don’t take into account seasonality), monitoring these KPIs could help indicate when levels of excess stock are rising.

Unfortunately, manually calculating these KPIs is time-consuming, and, if they’re not regularly updated, then you could easily miss any potential warning signs of stock levels beginning to rise!

That’s why many businesses use enterprise resource planning (ERP) or warehouse management systems (WMS) to help with their inventory management. These systems can track inventory levels, often in real-time, and provide basic KPIs to help monitor obsolete stock. Inventory optimization software, such as EazyStock, takes this one step further, calculating and reporting on healthy, excess and obsolete inventory levels of every SKU daily.

Obsolete inventory management

If you have obsolete inventory in your business, there are a number of ways to manage it and get rid of it. These include:

Sales promotions: you may be able to generate demand for the items if you sell them at a discounted price. Or, perhaps you can add them to product bundles, to make a different customer offer more attractive?

Find new markets: perhaps you can offer the products to a different marketplace, e.g. a different industry or country?

Sell to a stock surplus specialist: it’s possible to sell off obsolete inventory to a business specializing in selling excess, obsolete and liquidation stock. Be warned, you’ll do so at a heavily discounted price, though this could be a better option than writing it off altogether.

Writing it off: sometimes you have no choice but to dispose of the goods, e.g. they are out-of-date or have degraded in quality.

A proactive approach to inventory obsolescence

Having a plan to remove obsolete inventory is a necessity, but it’s also like closing the barn door after the horse has bolted! Taking a proactive stance is much wiser. With effective stock policies, you can proactively reduce excess stock and consequently avoid the problem of inventory obsolescence from occurring in the first place.

These include:

- Accurate demand forecasting

- Efficient stocking policies and real-time stock tracking

- Accurate re-order points

- Well-monitored KPIs

Read our blog on how to reduce excess and obsolete inventory for more advice.

Put your inventory obsolescence policy into action now!

Many companies are unsure what to do with obsolete inventory once they have it and make the mistake of not acting right away, as they want to avoid accounting implications. Be warned: if you don’t address obsolete inventory as soon as possible, it will just continue to grow.

Make sure you have a plan in place, and once you’ve reduced your obsolete stock levels, start to think about how to avoid getting into the same situation in the future. Inventory optimization software is one way to do this – contact our team today for more details.