How inventory optimization can help mitigate the financial impact of rising tariffs

Tariffs. A word you’ve probably heard more in 2025 than ever before – more than enough, even. However, it’s a word we’re going to hear a lot more of, so brace yourselves. Keeping track of the changes to the tariffs the US is imposing globally is a full-time job. Deadlines and deals constantly flux, making it hard for businesses to plan and budget for their inventory requirements.

If you’re struggling to stay up to date with the latest information, Reed Smith has created a Trump 2.0 tariff tracker, breaking down information by country, product, reciprocal expectations and other updates.

Rising tariffs significantly impact businesses and customers, as the additional costs of importing or exporting goods must be factored into the overall cost of the product. This leaves a decision for businesses – do they absorb the extra costs or pass them on to the customer?

Tariff uncertainty can also lead to disruptions in the supply chain. We’ve seen this recently with car exports from the UK to the US, where ports were overloaded with cars, resulting in delayed deliveries to dealerships across the country. This raises more questions for businesses – do they continue to import and export goods to countries with increasing tariffs? Do they look at re-shoring or near-shoring their suppliers to countries with lower tariffs to reduce costs and potential supply chain disruptions?

In this blog, we’ll explore how inventory optimization can help businesses be strategic in their response to increasing tariffs through:

- Cost savings and improved cash flow

- Improving demand responsiveness with data-driven decision making

- Improving supply chain efficiency

Understanding inventory optimization

Before we get into the benefits of inventory optimization, let’s start with an introduction. Inventory optimization is the science of balancing stock levels with demand forecasts to minimize inventory investment while maximizing service levels.

It’s a level up from inventory management, and with the right tools, can make a significant difference to the efficiency, employee satisfaction, and bottom line of your business.

If you’re relying on your enterprise resource planning (ERP) system for your inventory management, your demand forecast accuracy is likely hit or miss. This means you’re probably experiencing regular stockouts for some items while having excess stock of others. These are both costly, as stockouts lead to missed sales, while excess stock ties up capital that could be used elsewhere in the business. Your purchasing team is probably stressed and stuck in an endless cycle of checking thousands of lines in multiple spreadsheets, risking costly manual errors.

Inventory optimization software doesn’t replace your ERP system. Instead, it works with it to bring specialized functionality that drives your business forward. With ready-made connectors for many ERP systems, they are easy to connect and don’t require any business downtime.

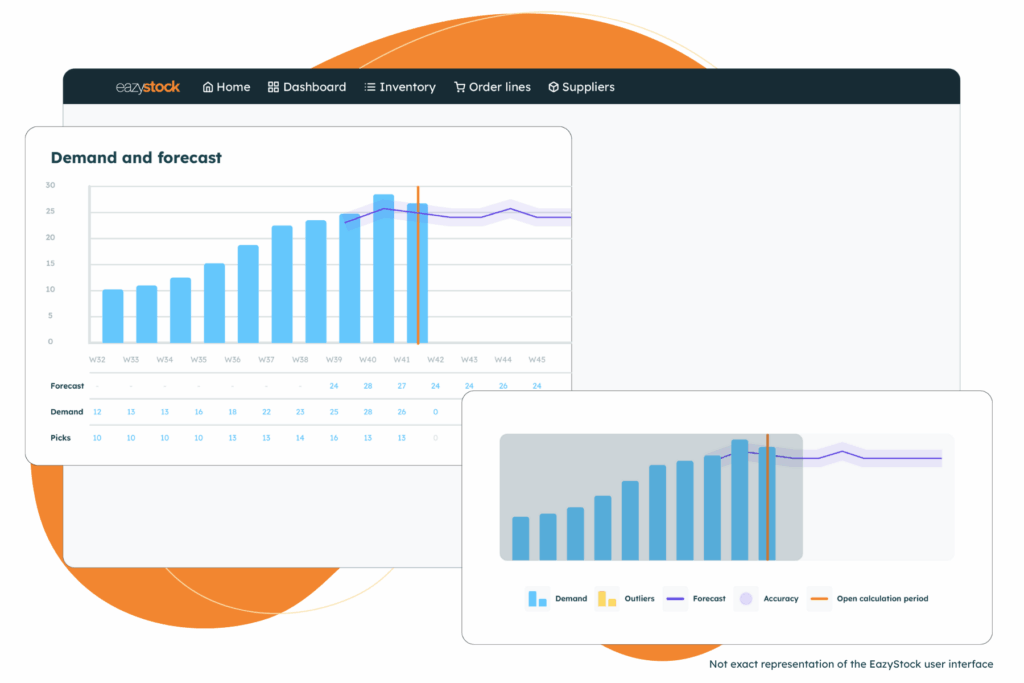

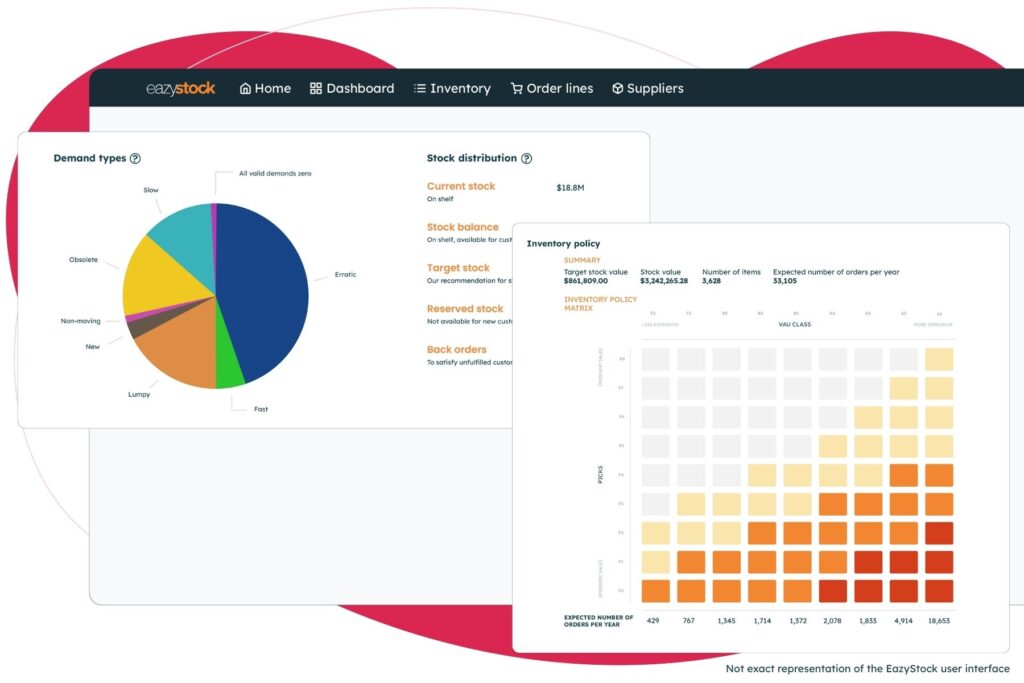

The software can produce more accurate forecasts than manual methods, as it can classify items daily, based on their stage in the product life cycle and demand profile. This enables it to select the most suitable forecasting algorithm, ensuring you only order items with actual demand.

It also eliminates the pain of manually calculating the EOQ, which is time-consuming and prone to error, and overcomes EOQ limitations.

How does inventory optimization help with dealing with tariffs?

Cost savings and improved cash flow

We already mentioned that increasing tariffs can increase inventory carrying costs. As the price of imported goods increases, businesses might order more to beat unit cost increases, but higher stock levels could lead to increased warehousing costs, longer storage times, and increased safety stock levels to cover supply chain disruptions.

If price increases are passed on to customers, demand may fall, resulting in slower inventory turnover and an increase in the time inventory is held in warehouses. If demand drops significantly or completely, there’s a risk of stock becoming obsolete, leading to costly write-offs.

If you aren’t using advanced forecasting algorithms and you’re relying on a rolling monthly average, it’s going to be even harder to predict demand accurately. This will increase the occurrence of over- and under-stocking.

Unlike spreadsheets, inventory optimization software constantly monitors forecasts, and its extensive alerts framework highlights any deviations from expectations – particularly around changes in tariffs. These alerts enable you to react to any issues and mitigate their impact.

Thanks to the advanced forecasting functionality of inventory optimization software, you’ll only order stock with upcoming demand, thereby minimizing investment. Inventory optimization software can reduce inventory levels by an average of 15-30%, resulting in savings of hundreds of thousands of dollars. Add to this the average sales increases of between 10% and 30% due to improved availability and a similar percentage reduction in stock-holding costs; the software costs pale in comparison.

With better control over the inventory you hold, you’ll free up more cash in the business. This can be invested in other areas of the business to support other strategic changes to overcome the impact of tariffs.

Data-driven decision making and demand responsiveness

We all make decisions based on gut feelings, but when hundreds of thousands of dollars are at risk, it’s good to back this feeling with data. Inventory optimization can help you leverage analytics for better forecasting and inventory management so you can be proactive rather than reactive.

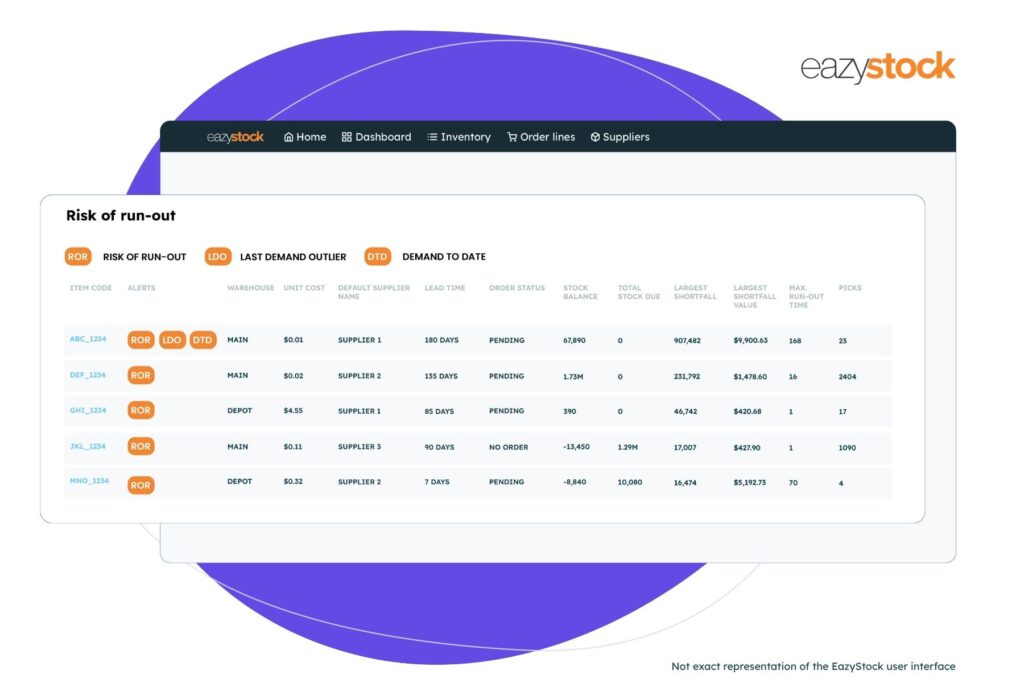

Instead of collating information from various spreadsheets, inventory optimization software connects to your ERP and other relevant systems to gather and share information, such as sales records, demand patterns and trends, supplier lead times, and production schedules. It continually monitors this data to provide a range of alerts when there are outliers, allowing you to check anomalies and understand if a spike or drop is a one-off so you can be more reactive. While the risk of run-out report allows you to bring orders forward or delay them as necessary

Rather than treating all items the same when it comes to forecasting, inventory optimization software can categorize and prioritize items according to their profitability and demand. ABC analysis or ABC classification is a basic way of doing this, but inventory optimization software goes beyond, incorporating more data variables, such as cost. This means that when tariffs are lower, you automatically order more. When they increase, you aim for a higher stock turn.

Segmentation can also be done by product group. If some groups are not affected by tariffs, you can isolate the tariff effect and manage them independently of those that are.

The system will then recommend inventory policies, reorder points and safety stock levels to meet demand and target service levels. Accurate safety stock levels reduce the chance of stockouts or excess stock. Rather than using fixed safety stock, time-based calculations, average/max calculations, gut feel or the ‘finger-in-the-air’ technique, safety stock calculations are data-led. Dynamic, statistical safety stock calculations are faster and consider more variables to meet demand and lead time variances. This makes them more accurate and reduces the risk and cost of human error. As they are calculated and updated daily, accuracy is maintained.

You can also use the order fill-up functionality to ensure you’re maximizing shipping container space or meeting minimum order requirements with items that have upcoming demand, rather than just adding any items to get the order over the line.

Just-in-time and Just-in-case inventory management

An eternal battle, do you choose just-in-time (JIT) or just-in-case (JIC) inventory management? JIT reduces inventory holding costs. You order what you need, when you need it, so you minimize stock levels and costs. However, any disruption in the supply chain will immediately impact your ability to meet demand.

JIC, on the other hand, means you hold additional stock beyond what you need to meet demand, covering any potential disruptions. You might already hold safety stock, but this would be in addition to that safety stock. While this provides you with a buffer, if you don’t sell that inventory and demand drops, you’ll be left with excess and potentially obsolete inventory.

The solution here is a combination of both, but knowing when to increase levels is hard without the correct information. That’s where inventory optimization can help. Dynamic stocking policies can help you respond to changes in lead time or unit cost. The system will adjust calculations to recommend new safety stock levels and reorder points. These could fluctuate as the market changes.

Supply chain efficiency

Enhancing relationships with suppliers and improving lead time can help to mitigate tariff impacts.

Let’s take a closer look at the questions we raised in the introduction:

- Do companies continue to import and export goods to countries with increasing tariffs?

- Do companies look at re-shoring or near-shoring their suppliers to countries with lower tariffs to reduce costs and potential supply chain disruptions?

First, you need to understand your supplier portfolio. Do you know where everyone is based, what items you buy from them, and how important they are to your business? Now, you can review the impact the tariffs will have on your business.

- What is the increase in unit cost?

- What is the increase in total cost?

- Can you absorb that cost?

- What will the impact be on the customer?

If you can’t absorb the cost increase, can you source the same items at a lower cost from a closer, alternative supplier? Adding a new supplier to your portfolio isn’t as straightforward as looking at unit cost. You also need to understand lead times and minimum order quantities (MOQs) to see if they are optimal. There’s no point ordering cheaper goods if the MOQ is so high that you end up with excess stock anyway.

A diversified supplier portfolio makes good business sense, so all of your eggs aren’t in one basket, ensuring you can maintain supply. For example, when tariffs rise in one area, you can easily turn off that supply and switch to another supplier in a different region without the hassle of trying to source new suppliers.

Inventory optimization software can help you understand if a supplier’s terms are beneficial to your business. By entering lead times and MOQs (whether values, pallets, or quantities), the software will check demand forecasts and let you know if it’s cost-effective.

Using the risk of run-out report, the software will help you decide when to use a faster but typically more expensive supplier. So, if you decide to source items locally to cover extended lead time, you only use it (and erode your margin) when you really need to.

The software supports supplier relationships, allowing you to vary time horizon and share them with your suppliers. This allows suppliers to ensure they can meet your demand, and enables longer commitments to new suppliers where it’s more cost-effective to purchase smaller quantities more frequently.

Diversifying your supplier base also helps mitigate the risk of supply chain disruptions. The further away your supplier is, the bigger the impact any delays or disruptions will have. These could lead to expensive modifications, such as paying for express delivery, using airfreight, or relying on backorders.

We have more information on supplier selection in our blog ‘Choosing the right supplier location strategy’.

Summary

Supply chains have been hit by relentless disruption recently. Businesses have had to adapt to the impact of Brexit, the global pandemic, wars, disruptions to shipping routes, and rising costs throughout the supply chain. It’s essential to consider long-term implications when planning a response to increasing tariffs. While you can take quick and immediate actions now, adopting a more strategic approach can ensure you’re able to respond to further changes more quickly.

The key issue when considering how to reduce the impact of rising tariffs is to reduce costs across the business. Inventory optimization can help you do this by:

- Providing enhanced forecasting methods to improve forecast accuracy

- Reducing inventory levels by 15-30%

- Improving stock availability to increase sales by 10-30%

- Reducing stock holding costs by 15-30%

Being proactive and engaging new inventory management strategies might seem expensive. However, the annual subscription fee for inventory optimization software like EazyStock is a tiny percentage of the potential hundreds of thousands of dollars you could save.

You’ll save money, improve customer service, and be able to pivot inventory management strategies faster and easier than before.

When you consider the benefits, it doesn’t make sense not to implement inventory optimization.

If you’d like to understand how EazyStock can help your organization, please contact our team to arrange a call or demo.