ForgeFix hits record stock availability with lower stock value

ForgeFix has been a specialist supplier of fixings and fasteners to the trade since 1991.

As one of the UK’s leading distributors of known fixings and fastener brands, they supply over 5,000 different product lines to trade customers such as construction, plumbing and heating vendors, DIY outlets, hardware stores, and businesses involved in trades like joinery, glazing, and roofing.

ForgeFix’s impressive growth is thanks to the wealth of experience and expertise within the ForgeFix team. This expertise enables them to highlight new product opportunities and extensions to existing ranges. Working closely with European and Asian manufacturing partners, they design and develop products for ForgeFix brands.

The challenge

ForgeFix managed thousands of SKUs using multiple spreadsheets alongside their ERP system, OGL. While this did some stock analysis, it wasn’t reactive and relied heavily on the team’s manual input and analysis. This could involve physically searching through all lines to try and spot issues, out-of-stocks, or errors.

“We were entering everything onto the system manually and doing orders line by line.”, says Emily Rowland, Purchasing Assistant. “It wasn’t viable because we were working on many Excel spreadsheets prone to human error.”

Even after spending time searching, Emily had to keep going back to check everything was right and enter the sales into the system.

“If you have a three-container order, it would take over an hour to enter everything.”

As Tony Armitt, Commercial and Technical Director, explains, after the pandemic, there were significant gaps in sales data due to stockouts, which made accurate forecasting impossible. They had been forecasting based on what they’d sold rather than the demand and what they could have sold if they’d had enough stock.

“We were doing a lot of manual calculations and using spreadsheets, so the data wasn’t right. We didn’t know what we should have been stocking and how much.”

To try and avoid stockouts, ForgeFix had designated one of their three warehouses to purely holding excess stock. This was full of stock they could use, but they weren’t sure when or how, so stock was accumulating, at risk of becoming dead stock and tying up money in the process.

ForgeFix wanted a system that could dynamically account for stock and work with more up-to-date data. They also wanted to be able to identify gaps and missed demand to ensure they were holding the right stock levels. This would enable them to track KPIs and provide the MD with more useful information to make data-driven decisions.

The solution

Tony discovered EazyStock at a trade show and was immediately drawn to its capabilities. Despite considering other systems, none could match EazyStock’s unique features, particularly its ability to handle multiple locations and bill of materials (BOM). Tony recognized that EazyStock’s multi-location functionality could effectively address the issue of excess stock in the overstock warehouse.

Automating analysis and getting rid of the spreadsheets sealed the deal, helping the purchasing team get back to doing what they did best – purchasing.

“Due to all the manual input, we didn’t have the time to analyze our stock and do the most we could as a purchasing team.”

EazyStock’s seamless integration to OGL was a winner for ForgeFix, as the set-up could be done without disrupting business operations.

The results

The ForgeFix team now operates with a newfound ease, thanks to EazyStock. Emily, in particular, no longer spends hours entering orders and checking the system.

Instead, EazyStock imports the calculated purchase orders to OGL hourly, freeing up Emily’s time to focus on managing stock. This shift has brought a sense of relief and efficiency to the team.

ForgeFix has improved its internal operations while enhancing its relationships with suppliers. More accurate forecasts and order schedules allow ForgeFix and its suppliers to plan more effectively, leading to better availability of materials.

Before we explore the results in detail, let’s see some top-level statistics:

- Improved stock availability to 97.3% – its highest point in years – ensuring that products are consistently in stock for customers.

- Reduced stock by more than 30%.

- Halved redistribution costs.

- Facilitated the redistribution of stock between warehouses rather than reordering. This has not only brought substantial savings, but also improved cash flow by freeing up funds tied up in excess stock.

- More than halved Emily’s workload by removing the need to manually input data, allowing her more time to analyze stock.

- Reduced out of stocks and the length of time products were out of stock.

Thanks to EazyStock, ForgeFix has eliminated inaccurate forecasting and no longer relies on spreadsheet reports based on previous monthly sales. EazyStock’s recommendations are now based on active sales, trends, and demand, ensuring they cover sales they might have missed before due to being out of stock. This accuracy instills confidence in the system’s capabilities.

Using the demand type change alert, Emily and Tony can now see how items are moving through their product lifecycle and how this affects the orders. For instance, if a good seller sees demand slow down or demand changes to non-moving, slow, or lumpy, EazyStock will automatically adjust the forecasting algorithm to ensure the right orders are placed.

In one example, EazyStock recommended an order quantity almost 40% above what ForgeFix thought was needed. This was because EazyStock calculated based on several months of missing sales due to stockouts. When Tony investigated, he found that EazyStock was right. Ignoring EazyStock would have meant a stockout because the data they worked from wasn’t considering the lost sales due to those stockouts.

Emily has hung up her investigation hat as she knows EazyStock’s alerts and the risk of run-out report will let her know what she’s running low on and what she needs to order.

As Tony anticipated, EazyStock’s multi-location functionality has proven to be a valuable asset for ForgeFix. It has made managing the warehouses a breeze, allowing the team to be proactive with EazyStock’s recommended orders and redistribution orders.

“Instead of ordering new stock from a supplier, EazyStock tells us when we can redistribute it.”, says Tony. “It’s helped with out of stocks and having the stock in the correct location at the correct time. We no longer need the overstock warehouse – EazyStock has helped to clear it out.”

As Emily explains, EazyStock benefits not only ForgeFix but also its suppliers.

“Before EazyStock, we were placing six months of orders in advance so the suppliers knew what they were doing and when the stock was required. We’d gotten into a system where we were doing this off last year’s sales, which meant we didn’t realize if demand had changed. We ended up overstocking or understocking items.”

Not anymore, thanks to EazyStock’s ability to consider supplier lead times.

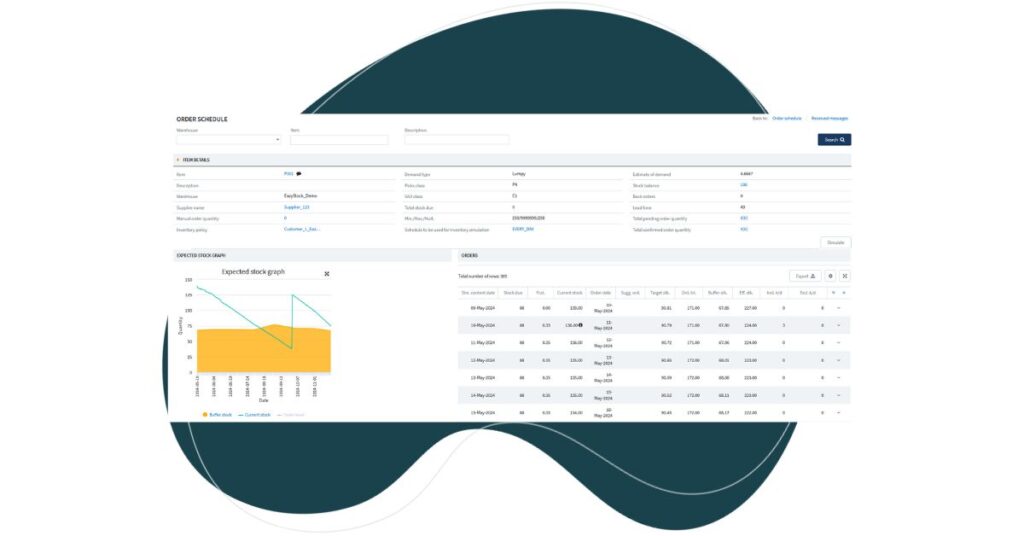

“Suppliers wanted more information on what we will be buying, so we now use the order schedule report.”, continues Emily. “They know this isn’t an order, but it provides a forecast from EazyStock so we can help them plan for the materials they need, which ultimately helps with availability.”

The order schedule report also helps suppliers adhere to their lead times. If they know which materials they need in advance, they can ensure they have them in time and don’t have to rush around trying to get them on short notice.

It also helps to bring the price down. If they know it’s a good time to buy the materials, they can get a better price and pass the cost savings onto ForgeFix.

Emily and Tony can’t speak highly enough of the training and implementation support they received from their dedicated Customer Success Manager, Cristina, as Emily explains.

“EazyStock has been one of the best companies we’ve worked with as a business on a project. If you ask anyone in the company, they’ll say the same. Cristina has always been there to help us with anything we need. She gets back to us so quickly and has been so helpful. They made the process so easy and simple for us.”

Tony echoes this: “We’ve used a number of software companies for different projects, and EazyStock has been the best software company we’ve ever used.

“They’re always telling you what you need to know because they actually understand the product and can usually answer questions. Cristina is excellent. She knows exactly what she’s talking about, and that makes it very easy.”

Cristina delivered tailored on-site training sessions and workshops to ensure the team could check data and was up-to-speed with everything EazyStock. “It’s really important to ensure the training works for each customer because it can be daunting when you go and do it on your own when you’re relatively new to a system.”

The team found the practical sessions particularly helpful.

“Cristina would explain something; then we could watch what EazyStock would do and how it could work for us. If we needed anything over email, she was always there. It was like she was sitting next to us!”

Cristina initially provided weekly review sessions, so if the team wanted to discuss anything, she could run through it on her screen.

“We’ve gone down to monthly review calls now, but Cristina always responds really quickly,” says Emily.

When asked what she would say to anyone still managing their stock using spreadsheets, Emily said, “Don’t think twice and make the jump today because it’s saved me so much time. I can now spend my time planning rather than just inputting orders based on erroneous historical data. Supplier relations are so much better because I actually have the time, thanks to not having to do things manually.

“EazyStock has helped with everything related to purchasing. It’s like a little purchasing portal. It’s amazing.”

Tony agrees, “From our point of view now, you trust the information you’re getting. I’d recommend EazyStock every time. After all the years I’ve spent struggling with spreadsheets, it’s just made everything so much easier. It also gives you confidence that the numbers are right, which you don’t get from doing it manually.”

Read more of what EazyStock’s happy customers have to say here.