8 demand forecasting techniques for better inventory management

What is demand forecasting?

We can’t accurately predict the future without being able to travel through time. So, when it comes to inventory management and how quickly demands change, how do you know the amount of stock you should hold? You use demand forecasting.

However, demand forecasting is one of the biggest challenges in supply chain management.

Demand forecasting or inventory forecasting is how you can accurately predict customer demand for stock items over an upcoming defined period. Demand forecasting is usually done by reviewing historical data, e.g. past consumption or sales data, sales forecasts and production orders. This is then combined with qualitative knowledge of seasonal trends, market trends, and events, such as promotions and marketing campaigns, to forecast future values and improve accuracy.

Forecasts are only as good as the data and method used to calculate them. Before you start forecasting demand, you need to determine what you’re trying to find out so you can choose the best demand forecasting methods.

The importance of demand forecasting in inventory management

Whether you’re a manufacturer, wholesaler or retailer, demand forecastingis critical for effective stock and supply chain management. If you can accurately predict demand, you can take action to ensure you hold the correct amount of stock to deliver high fulfilment rates or service levels. Accurate demand forecasts also reduce the risk of stockouts, production disruption and lost sales.

As the supply chain depends on each link to work efficiently, demand forecasts can help inventory and supply chain management teams map out how to maintain appropriate inventory levels and meet customer demand.

Ensuring you have the necessary stock to meet customer demand helps maintain customer satisfaction and retention. You can also build strong relationships with your suppliers by providing accurate order information to them to reduce the need for rush orders.

Accurate inventory forecasting allows you to efficiently meet consumption requirements or fulfil customer orders without investing in large amounts of unnecessary stock. This effectively helps you lower overall operational costs, such as storage and carriage costs. Accurate forecasting enables you to hold the right amount of inventory without over- or under-stocking for optimum inventory control.

However, accurate inventory forecasting is no mean feat. This post highlights some of the most common demand forecasting techniques and explains their benefits.

Demand forecasting techniques

Demand forecasting techniques can be as basic or as complex as you make them. Some forecasting models use quantitative forecasting (historical demand data) and qualitative forecasting (based on more subjective opinions and insights).

Choosing the best demand forecasting method isn’t an exact science, and there isn’t a one-size-fits-all option. The most accurate forecasts usually combine different demand forecasting methods and data types.

Your demand forecasts can be long-term or short-term, internal or external and passive or active.

Long-term demand forecasts are anything from one to four years, while short-term forecasts are under one year.

Internal demand is relevant for demand planners, as it looks at the internal capacity to meet demand with existing resources. External demand planning considers wider information, such as consumer demand trends, spending patterns and what’s happening in the wider economy.

Active demand forecasting is dynamic and can change depending on economic trends and internal growth plans. This is particularly relevant for new products or those with unstable demand. Passive demand forecasting only uses historical data.

One of the simplest and most common inventory forecasting techniques and an example of passive forecasting is calculating moving average forecasts. This is when you take a previous period’s demand data (e.g. four weeks of sales data) and calculate the average demand over that period (average sales per week). You then use this average as the forecast amount for the coming period.

This method works well for inventory items with stable demand and where previous actual demand is a good indicator of the future forecast period. However, this isn’t often the case in today’s disrupted marketplaces.

Many businesses struggle with simple demand forecasting techniques because they don’t consider the different demand patterns of their stock items. They also fail to account for external market factors that lead to demand volatility.

Let’s look at how you can include them in your forecasts!

8 of the best demand forecasting techniques

Here are our eight top demand forecasting techniques to improve your inventory management:

- Use demand types

- Identify trends

- Adjust forecasts for seasonality

- Include qualitative inputs

- Remove ‘real’ demand outliers

- Account for forecasting accuracy

- Understand your demand forecasting periods

- Consider demand forecasting software

Let’s take a closer look at each in more detail:

1. Forecasting inventory using demand types

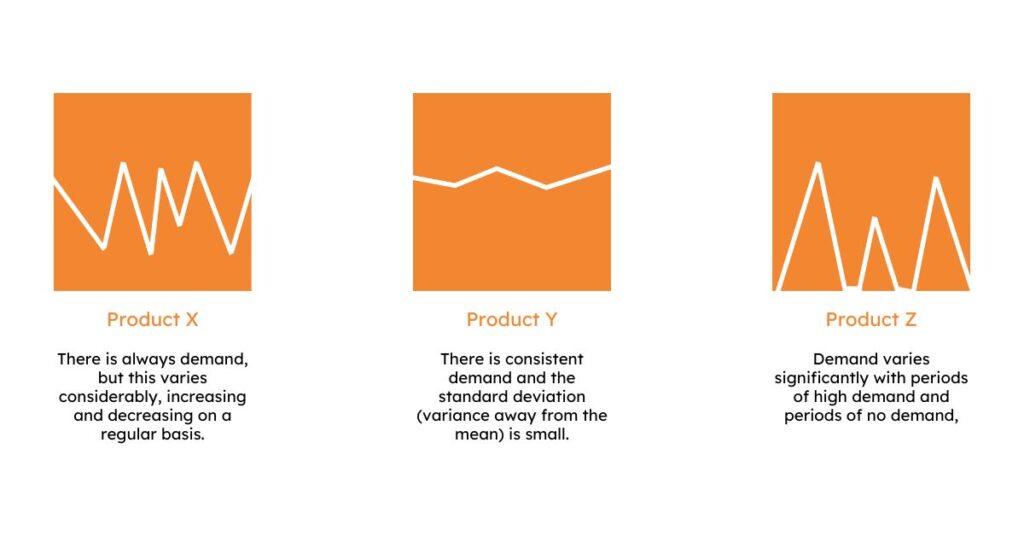

If you analyse the historical sales and consumption data of every stock item in your warehouse, you’ll find their demand varies considerably. Some will have consistently high or low demand over time, while others could have sporadic or erratic demand.

For example:

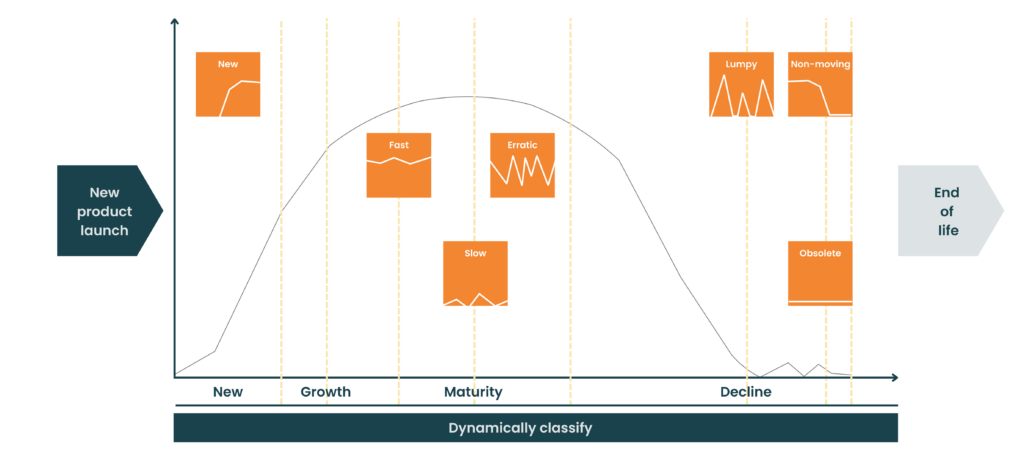

In addition, as stock items move through their product lifecycle, from market entry, to maturity and decline, their demand types will keep changing:

To forecast your base demand effectively, you should identify and then use an item’s demand type. You can then use this to determine which calculation (or algorithm) will produce the most accurate forecast. It makes sense to use one algorithm for a product with erratic demand and another for a product with slow demand.

2. Including demand trends

Demand for your inventory items will ebb and flow due to trends in the market. For example, fashions change, new technologies replace old ones, and social, economic, and legal factors influence demand.

Items will also follow demand trends as they move through the product cycle. For example, in the growth phase, there will be an upward trend in demand, which will reverse in the decline phase.

To understand if there are trends in demand, you will need to use more granular sales data to see how specific customers and different types of customers are likely to purchase. Don’t include seasonal data when identifying trends data, as this is not the same as a trend.

Ensure you look out for such trends in your demand data and adjust your inventory forecasts accordingly. Creating a forecast based solely on your base demand will be useless if items are following a specific trend projection.

3. Forecasting demand for seasonal items

Almost every manufacturer, distributor or retailer can expect seasonal demand fluctuations for some of their product lines. Seasonal weather patterns, school holidays and annual traditions all influence demand, but differently to trends.

Understanding how these seasonal factors affect your production levels or customer purchasing habits helps you capitalise on demand peaks and plan for troughs.

It’s best practice to keep seasonal demand factors separate from your base demand calculations. This keeps the data clean and easier to use for forecasting going forward.

4. Include a qualitative forecasting method

Whilst historical data (quantitative demand forecasting) provides an excellent basis for achieving demand forecasting accuracy, sometimes you’ll also need to consider more qualitative factors.

Qualitative demand forecasting includes accounting for future events and external market factors, such as sales promotions, marketing campaigns and competitor activity. It essentially involves asking for ‘human input’. You could ask for expert opinions from your sales and marketing teams, customers and suppliers about their thoughts on upcoming orders.

Qualitative forecasting methods are beneficial for erratic or unstable demand. They also help when you don’t have any historical data to use, such as with new products.

Some examples of qualitative methods include:

- The Delphi method – You gather an expert panel of industry leaders to provide their opinion over several rounds of questionnaires to, hopefully, reach a consensus. This is helpful when there is an industry-level question, such as around the impact of AI on your industry, although it can be used continuously.

- Salesforce composite forecast – As your sales teams talk to customers and prospects daily, ask them how much they realistically expect to sell over your forecast period and add them up. You will need to make adjustments for sales from other channels and for over/under sales confidence.

- Interviews and focus groups – Holding focus groups and speaking to customers directly rather than using surveys can bring more insights, as you can delve into things in more detail.

This could be asking for opinions from your sales team, or speaking to customers and suppliers about their thoughts on upcoming orders. Qualitative forecasting methods are especially useful when demand is erratic or unstable, or when you have no historical data to use, such as with new market entrants.

5. Inventory forecasting outliers

Demand outliers can come from known actions or unpredictable events. Known actions include sales promotions, large one-time orders and employee strikes. Unpredictable events include competitors going out of business, natural disasters and economic events.

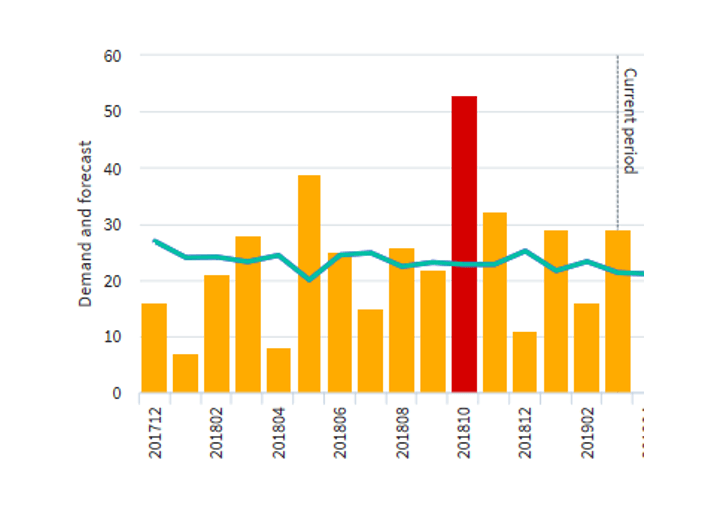

Demand outliers can significantly skew the accuracy of your forecasts, whether high or low. You need to identify any demand data outside the reasonable standard deviation of average demand. You then need to decide whether to include the outlier in your demand forecasting calculations. If it’s part of a trend, you should include it. If it’s an anomaly in demand, it’s better to leave it out.

This also includes periods of stock-outs. Exclude these from your forecasts, or they will incorrectly bring them down overall.

For example, there’s a period where you only sold/used 10 of one item because that’s all you had in stock. You could have actually sold/used 200 with the right availability. Here, you should ensure you don’t reorder based on a forecast using 10 sales. Otherwise, you will miss out on another 190 sales. Flag periods for exclusion or make an assumption about the lost sales/consumption and add this to the forecast.

6. Understand demand forecasting accuracy

It’s unlikely your demand forecasts will be 100% accurate. If you can calculate the error level in your previous demand forecasts, you can factor this into future forecasts. Determining the uncertainty of a forecast for a given business period allows you to adjust inventory management rules accordingly. This could be increasing safety stock levels to cover uncertain periods of demand.

There are many formulas to help you measure demand forecast accuracy, or forecast error. The Mean Absolute Percent Error (MAPE) calculates the mean percentage difference between actual and forecasted demand over a given period. The Mean Absolute Deviation (MAD) shows how much the forecasted demand deviates from actual demand in units. You can learn more about forecasting error here.

7. Demand forecasting periods and reviews

The period you choose for your demand forecasting directly impacts your forecast accuracy. Short-term demand forecasts are more accurate than long-term demand forecasts. For example, a forecast looking at your inventory’s demand over the next two weeks is more likely to be accurate than a 12-month forecast.

In addition, if markets are volatile or items have erratic demand patterns, you should review your forecasts more regularly. If you experience stock-outs or see cases of excess stock, you may need to adjust your forecasting intervals.

8. Consider demand forecasting software

Accurate demand forecasting is not a simple task. Especially if you want to track each stock item in a large portfolio. Inventory forecasting requires an accurate picture of real-time stock levels in your warehouse and future orders or sales across each channel.

Often, the demand forecasting functionality of enterprise resource planning systems (ERP), warehouse management systems (WMS), and eCommerce platforms is limited. Investing in demand forecasting software will enable fast and accurate demand forecasts, no matter how complex or varied the demand is.

Statistical demand forecasting systems like EazyStock ensure you can swiftly and accurately complete your complex demand forecasting requirements. Quick and accurate forecasts reduce stock-outs, decrease cash tied up in inventory and, most importantly, meet customer demand.

If you’d like to improve how you forecast demand and find out more about EazyStock’s inventory forecasting capabilities, please email us or call us on 0121 312 2992.