Automotive Inventory Management Explained

The rapidly changing automotive industry

The technological revolution in the automotive industry is mind-blowing: connected cars, automated supply chains, and the shift towards electric and hybrid vehicles are all happening at a rapid pace. In addition, the political climate is directly affecting the automotive industry: Brexit, border controls, customs, and emission laws are all issues that manufacturers and distributors must react to. This all adds to uncertainty, and you must be agile enough to respond to all these changes to stay competitive.

One increasingly important area to focus on is inventory management with the rapidly changing supply, demand and spare parts needed for the new types of vehicles produced. It’s, therefore, important to optimise inventory management by using appropriate solutions.

This blog post will show you how poor stock management can be devastating for car dealers and wholesalers and how well-managed inventory is a competitive advantage.

From push to pull

One of the main disruptions is the change in consumer behaviour. For decades, car manufacturers regularly pushed new models into the market, producing them in large numbers, allowing customers to choose from a range of readily available models. This provided a decent level of certainty in the industry and meant that manufacturers and wholesalers could predict the demand for spare parts pretty well.

Now, the “pull” principle has taken over, and the industry is increasingly focused on customers’ actual needs. Customers can configure their cars based on various options depending on their needs. While great for the consumer, this level of flexibility poses significant challenges to many industry players due to the unpredictability of demand for different components in the automotive aftermarket. The complexity of inventory management also increases with agile production methods and the increase in e-commerce, which makes manual processes outdated.

The bigger Original Equipment Manufacturers (OEMs) are generally one step ahead and rely on advanced software for inventory optimisation, forecast calculation and purchasing automation. However, more and more medium-sized industry representatives have recognised the benefits of automation, especially those who can connect to the systems of their suppliers and customers.

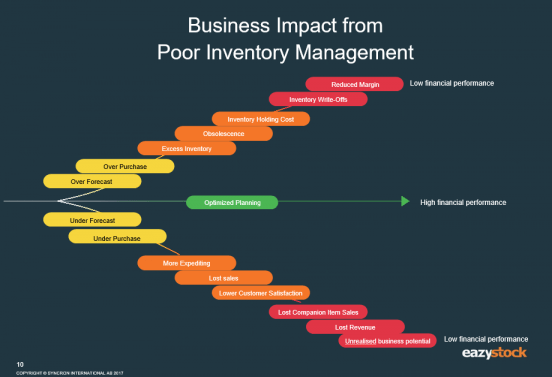

The effect of poor inventory management

So how do bad stock management processes affect automotive industry wholesalers, and why is it crucial that businesses deal with this issue before it’s too late?

Too little stock

The most obvious immediate impact is lost orders and customers. Customers demand a certain delivery time, depending on the product. When you fail to deliver on time, it’s easy for a competitor to take your customer – and once you’ve lost a customer, it’s really hard to win them back. However, it’s not only your current customers at stake – with the rise of online evaluations and reviews, a bad reputation can spread like wildfire on the web. This is even harder to recover from and can even, in the worst case, lead to the failure of your company.

Too much stock

On the other hand, if you keep too much stock to guarantee high product availability, your business is in a much weaker financial position. Not only are you tying up capital that could be invested elsewhere, but you also risk ending up with old inventory that decreases in demand and value as new cars enter the market.

Writing off or selling at significant discounts to get rid of old stock can be devastating in an uncertain market, as you lose the margins that would help keep your company afloat if the industry takes a sharp turn.

The right amount of stock

As in so many cases, the right way is the middle way. If you can have the right items in the right quantity at the right time, you will be in a much better position to serve your customers and respond to change. Simple!

These inventory management challenges aren’t new, but they have become more prevalent due to growing uncertainty factors. The good news is that there are ideas, processes and tools to help you manage the challenge.

Cracking down on bad inventory management

First, you need a good demand forecasting process. Mathematical models and algorithms can analyse stock history and calculate future requirements for each inventory item. Based on this, it’s also possible to identify outliers and trends and implement a warning management or automated inventory replenishment system.

Other methods include inventory classification, such as ABC or XYZ analysis. For example, a typical ABC analysis shows which customers or products are the most likely to be involved (A) and the least (C). The accuracy of these classifications can be tested with simulations of potential inventory scenarios.

These concepts have proven to be successful, but they must also be applicable in a manageable form since no company has the resources to use such calculations and algorithms manually every month.

Most companies have an ERP system that often offers inventory and purchasing management modules. These modules allow companies to automate their inventory planning and improve the accuracy of their demand forecasts.

However, due to the changing conditions of the automotive industry, it’s recommended to go a step further. Many companies in other rapidly changing industries are realising their ERP isn’t powerful enough to see the full potential of inventory optimisation. That’s where inventory optimisation software, such as EazyStock, can help/

Is your company ready for a rapidly changing industry?

Knowing you need to be prepared is one thing, but how do you get your warehouse into shape to outlast any upcoming twists and turns? Take a quick look at our inventory health assessment to see where you can strengthen your inventory. Answer these 12 short questions to analyse your warehouse and see how you can improve your inventory management strategies.