HVAC Inventory Management and Supply Chain Issues

Market trends for the HVAC industry

The HVAC industry is unforgiving to distributors who are not on top of their game. HVAC has a constantly growing market – especially a growing global market as emerging economies ramp up construction and additional end-users emerge (such as data centers who need to keep their machines cool and ventilated). Plus HVAC equipment is also being adopted more and more by consumers due to technological innovations and climate change driving both affordability and demand respectively. While demand is growing, so too is supply – and with it, distributors. The HVAC industry is already highly competitive and is predicted to grow 13% through 2028.

But increased competition isn’t the only obstacle that HVAC distributors face. New energy efficiency regulations and standards are set for 2023 regarding certain HVAC systems, making it past time for distributors to start sourcing suppliers and diversifying their product portfolios for the products they’ll need in order to keep up with a new demand.

With an ever-expanding market and continuous industry updates, HVAC distributors already have a lot to keep track of without trying to manually keep track of their inventory.

Inventory challenges for HVAC industry

Seasonality

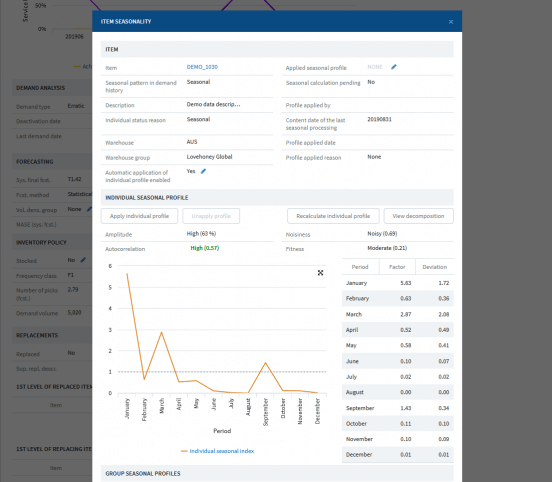

One of the most notable challenges for the HVAC industry is seasonality. An obvious example: air conditioning units are a hot commodity in the summer while demand for devices and units for heating is reserved for the cooler months. To meet this demand, suppliers and distributors need to prepare months in advance – even years in advance, in the case of units and devices to meet future regulations.

While you could dive into your Excel file where you keep your inventory management and try to remember all the SKUs you need to order in advance while trying to figure out the order quantities, a much more efficient and accurate way to prepare for seasonal surges and slumps is with an inventory optimization tool automatically calculating order points and quantities.

What an inventory optimization tool like EazyStock will do is assign seasonal profiles to SKUs based on their demand history. Then, when its time to order items so that you have them for the spike in demand (factoring things like lead times into account as well), EazyStock will send you a purchase order for your approval. No trying to remember when to order how many of which items from what supplier; the solution does the work automatically and accurately for you.

Complete inventory overview

Managing a vast number of SKUs across the entire supply chain is no mean feat. At minimum, inventory management includes sourcing from the right suppliers, accounting for lead times as well as their ability to fulfill orders, storing and shipping inventory, and continually analyzing and reordering. The bigger the supply chain operation, the more complex the inventory management becomes.

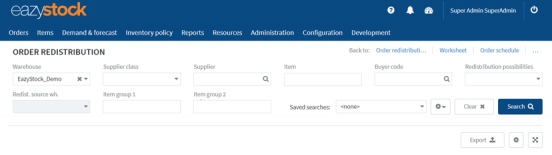

HVAC distributors often have multiple sites where they keep inventory. Multi-echelon inventory management adds another layer of complexity – inventory redistribution, differing demand at different locations, increased costs, etc. In some cases, the inventory storage locations aren’t even necessarily warehouses – they can even include spaces like showrooms.

It’s impossible to manually manage so many moving pieces accurately. Even an Enterprise Resource Planning (ERP) software with an inventory management module will only go so far. Typically ERP inventory management will recommend orders based on static values and not give accurate seasonal forecasts. With an inventory optimization solution, you’ll receive dynamic order recommendations based on forecasted demand for all SKUs across all echelons and inventory redistribution recommendations so you’re not needlessly tying up capital in additional inventory.

Adding inventory optimization to your solutions

When it comes to inventory management for HVAC distributors, most small- and mid-sized businesses (SMBs) think they are too small to invest in inventory optimization solutions. These same HVAC distributors report having large gaps in supply chain visibility which lead to disorganized and inefficient inventory operations. By ignoring automated solutions, SMBs are giving up the very tool that would give them a competitive edge.

The software will automatically keep on top of your inventory management so you can spend your time growing the business in new ways – sourcing new suppliers for new products, diversifying your portfolio, even building your customer base.