How to manage dead stock

Having enough stock to meet demand is fundamental to stock-holding businesses. Running out of stock leads to lost sales and lost customers. While it’s tempting to increase inventory levels to be safe, ordering too much stock can result in obsolete items, which is just as costly.

What is dead stock?

Dead stock, also known as obsolete stock and obsolete inventory, refers to items without demand for a sustained period. This is usually because sales have died out as items reach the end of their product life cycle or components are no longer used in their supply chain.

Why is dead stock a problem?

Obsolete stock can be problematic for several reasons:

- It costs money to store, increasing inventory carrying costs

- It absorbs working capital that could be spent elsewhere in the business

- It impacts financial statements and looks bad on the balance sheet

- It’s often sold at a lower net resaleable value or written off altogether, affecting profit margins

Why do businesses have obsolete stock?

Poor demand forecast accuracy

Dead stock is usually caused by poor demand forecasting and inadequate inventory planning and purchasing. Companies that haven’t accurately spotted a decline in demand and adjusted their stock replenishment policies accordingly will see excess stock build up in their warehouses. As demand disappears altogether, these items will become obsolete.

Overproduction

Overproduction is connected to poor demand forecasting. If you aren’t accurately forecasting demand, you could produce more items than needed. Overproduction could also be down to misaligned and inefficient production schedules and processes.

Changes in customer preference

Surplus inventory can also result from quick changes in consumer trends, fashion or technology, or the market may simply reject a product. In all cases, effective demand forecasting and inventory management processes can prevent this from happening.

Competition

Not keeping on top of competitor activity, such as new product launches and promotions, can be detrimental to your ability to react quickly to market changes. If competitors bring in new products that are better or cheaper than yours, you could see demand shift away from your products to theirs.

Product and technological changes

Technological changes and advancements are happening rapidly; newer, better models are replacing older ones. If you aren’t keeping up with emerging technologies and incorporating them into your product development strategy, you could end up with outdated, unsellable products or components.

Regulatory changes

Obsolete stock can occur due to changes in regulations. If your products are no longer legal or compliant, you won’t be able to sell them.

Poor inventory management software or techniques

Many companies use enterprise resource planning (ERP) or warehouse management systems (WMS) to manage their stock. While these platforms will have some basic forecasting and purchasing functionality, most lack the sophistication to track stock as it moves through its product life cycle or alert users when they have excess stock so they can prevent obsolete inventory from accumulating. Many users resort to Excel spreadsheets, but these can be time-consuming to create and keep up to date, leading to inaccuracies.

Product quality/unhappy customers

If your customers have had bad experiences, whether with poor quality items or customer service, they will likely find a more suitable supplier. If you don’t have appropriate quality control or aren’t focusing on your customers’ needs, and they can find better products and services elsewhere, your items will remain unsold.

How can you prevent dead stock?

If you already have excess or obsolete stock, you can read our blog on how to reduce levels.

How can you avoid obsolete inventory in the first place? Proactivity is key. Here are some tried-and-true ways to reduce excess stock in your supply chain and help prevent obsolescence.

Improve demand forecasting accuracy

Accurate demand forecasting is critical to holding enough stock to meet customer demand without investing in unnecessary stock that could become obsolete. Additionally, holding optimal stock levels will reduce storage and carrying costs.

Manual demand forecasting with spreadsheets and paper is tricky. It’s hard to see trends, keep track of data and manage algorithms and calculations to ensure accuracy.

There are different demand forecasting techniques – some complex and some basic. The same forecasting technique won’t work for all businesses, so finding the right method is important. Our eGuide explains how to improve forecasting accuracy in more detail.

Monitor trends

As mentioned above, keeping on top of customer preferences, market changes, technological advancements, competition, and regulations is vital to avoiding obsolete stock.

Combining this qualitative data with quantitative data provides more rounded forecasting, reducing the risk of obsolete stock.

Review replenishment policies

With good inventory policies in place, you can aim to avoid obsolete stock. Adjust your reordering parameters to match demand and reduce stock levels.

During supply chain disruption periods, buying large quantities of stock is tempting to avoid stockouts and meet demand. Similarly, if a supplier offers you a discount for a bulk order, it might seem to make financial sense, but it won’t if you can’t sell everything.

It’s essential to have robust replenishment policies and strategies to avoid excess and obsolete stock. Accurate and optimal replenishment involves reviewing and understanding factors, including lead times, supplier constraints, safety stock levels, promotions, discounts and seasonality.

While you can manage this manually, it’s time-consuming and complex. Automating these processes with software that can use complex algorithms and calculations will speed things up, increase accuracy and make it easier to respond to market changes. You can read more about effective stock replenishment in our blog.

Consider whether you can redistribute stock between warehouses if one faces a stock out. Stock redistribution avoids buying unnecessary items that could become obsolete.

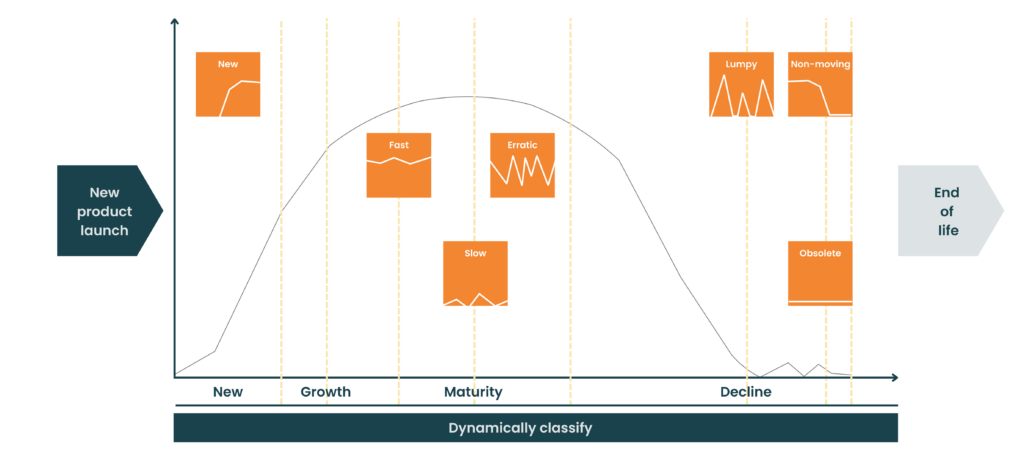

Track items through their product life cycle

Ensure you can track each inventory item through its product life cycle and monitor its consequential demand pattern. This allows you to identify products coming to the end of their life cycle and beginning to experience negative demand, e.g. in a continuous decline or lumpy demand (periods of low and no demand). Check if these ebbs and flows are due to seasonality so you can manage replenishment policies throughout the year.

Items with slowing demand are called ‘slow-moving’ items. It’s essential to carefully monitor the stock levels of these items and their associated demand so you can pinpoint any excess inventory (when available inventory is much higher than forecasted demand) and ‘take action’ before any items reach obsolescence.

Where relevant, work with your sales and marketing teams to consider promotions as items become slow-moving or move to the end of their product lifecycle. If you can sell the goods at a reasonable price or mitigate damage to your bottom line, you’ll still achieve a respectable profit margin.

Strengthen supplier relationships

Collaborating closely with suppliers can help businesses react faster to market changes and adjust orders accordingly. Building strong supplier relationships ensures better communication, faster response times, and more flexible terms, ultimately reducing the chances of accumulating obsolete inventory.

Using automation to improve obsolete stock management

Inventory management systems do a great job tracking inventory movements along the supply chain. Unfortunately, inventory management software often falls short when accurately forecasting demand and recommending what stock and quantities to order. This makes it difficult for inventory managers to prevent accumulating excess and obsolete inventory. Adding an inventory optimization tool like EazyStock to enterprise resource planning (ERP) or warehouse management systems (WMS) can enhance their functionality and improve forecast accuracy.

EazyStock tracks every SKU along its product life cycle, so excess stock and items with declining or lumpy demand are identified with plenty of time to take action. EazyStock dynamically adjusts statistical demand forecasts, stocking policies and reordering parameters to prevent overstocking. As products reach the latter stages of their lifetime, stock levels are reduced accordingly.

With replenishment parameters, such as safety stock, reorder points and reorder quantities automatically updated, inventory managers no longer need to spend hours crunching numbers and hoping for accurate results. Instead, they can focus on acting on the data and spending time on more strategic activities.

If you’d like to assess the ‘health’ of your inventory and your stocking policies, simply download our Inventory Health Self-Assessment below. For a demo, contact us today.