Safety Stock: How to Manage Safety Stock Levels

Safety stock inventory (also called buffer stock) is a term used by inventory and logistics managers to describe a level of extra stock that is maintained to mitigate risk of stockouts (shortfall in raw material) due to uncertainties in supply and demand.

Safety stock is an addition to normal or basic inventory that serves as a buffer against variability in the supply chain. One of the biggest factors of variability in the supply chain is demand itself, and demand can be highly unpredictable occurring in different demand type patterns.

Safety stock challenges

The challenge for all inventory planners is to effectively balance the level of basic stock required to maintain your target service level, keeping as little safety stock as possible on hand and providing ‘just the right amount’ of seasonal stock to make sure you don’t run out.

Intelligently adapting to widely-varying demand behaviors is the key to better safety stock results enabling companies to save money while still meeting service level requirements.

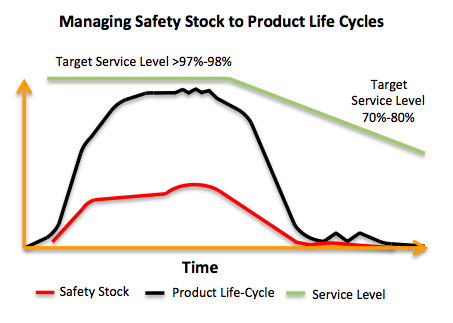

Most safety stock inventory management tools on the market assume either a coverage period or a normal distribution and thus almost always over estimate the quantity of safety stock necessary to cover the variability leading to inflated costs and excess stock. In the graph below, you will see how safety stock calculations, as well as, service level targets fluctuate based on the life-cycle stages of a product.

Safety stock calculations in advanced optimization tools such as EazyStock are adaptive and dynamic following the different demand types as they are more or less variable. Higher accuracy is achieved for certain demand patterns if using Poisson distribution or negative binomial distribution are used.

The target service level, or target fill rate, is a key input driving the size of the safety stock alongside with the demand variability. Ideally, you should set the stock at such a level that means you will be able to cater for each and every demand and supply fluctuation.

In theory, to do that you would need to set the service level at 100%. In reality, this approach is not financially defendable, so companies should strategically setting different target service levels for different demand types and ABC classification.

Learn More

Download our free white paper that covers the different methods for calculating safety stock in greater detail. Additionally, learn about strategies for finding the right balance between inventory costs and customer service levels.

White Paper Topics Include:

- The basics of safety stock management

- Why should companies carry safety stock

- Methods of calculating safety stock

- Calculation equations & examples